Open large image in new tab »

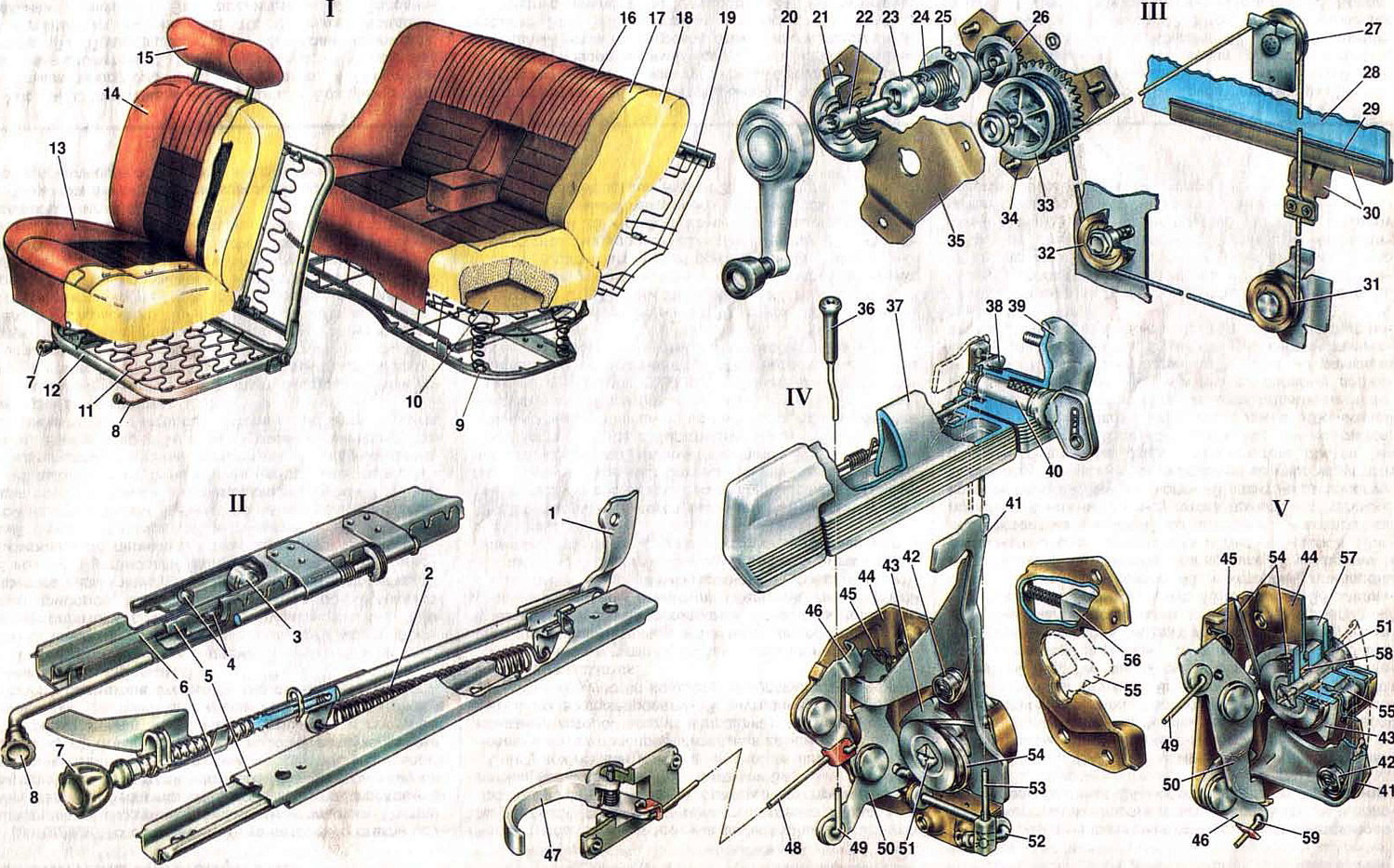

Pic. 33. Body equipment.

1. Front seat backrest reinforcement; 2. Spring back tilt mechanism; 3. Roller; 4. Balls sliders; 5. Sled sliders; 6. Slider guides; 7. Screw with the handle of the backrest tilt mechanism; 8. The handle of the seat movement mechanism; 9. Hole for fixing the seat cushion; 10. padding backing; 11. Frame spring; 12. Pillow frame; 13. Pillow; 14. Back; 15. Headrest; 16. Rear seat upholstery; 17. Upholstery backing; 18. Back padding; 19. Rear seat back frame; 20. Power window handle; 21. Handle trim; 22. Drive roller; 23. Brake spring driver; 24. Brake spring; 25. Drive roller support; 26. Drive gear; 27. Top roller; 28. Sliding door glass; 29. Gasket; 30. Glass clip; 31. Lower roller; 32. Tension roller; 33. Drum with driven gear; 34. Power window housing; 35. Housing cover; 36. Lock lock button; 37. External door handle; 38. Leash of the lock switch; 39. External handle housing; 40. Lock switch; 41. The lever of the external drive of the lock; 42. External drive lever spring; 43. Ratchet; 44. Lock case; 45. Spring lock lever; 46. The lever of the internal drive of the lock; 47. Internal door handle; 48. Traction of the internal drive; 49. Thrust of the button of blocking of the lock; 50. Lever for blocking the lock; 51. Central roller; 52. Lock release roller; 53. Lock switch rod; 54. Ratchet spring; 55. Rotor; 56. Lock cracker; 57. Support washer; 58. Bushing of the central roller; 59. Intermediate rod of the internal drive; I. Seats; II. Skid front left seat; III. Power window front right door; IV. Front left door lock; V. Rear left door lock.

1. Front seat backrest reinforcement; 2. Spring back tilt mechanism; 3. Roller; 4. Balls sliders; 5. Sled sliders; 6. Slider guides; 7. Screw with the handle of the backrest tilt mechanism; 8. The handle of the seat movement mechanism; 9. Hole for fixing the seat cushion; 10. padding backing; 11. Frame spring; 12. Pillow frame; 13. Pillow; 14. Back; 15. Headrest; 16. Rear seat upholstery; 17. Upholstery backing; 18. Back padding; 19. Rear seat back frame; 20. Power window handle; 21. Handle trim; 22. Drive roller; 23. Brake spring driver; 24. Brake spring; 25. Drive roller support; 26. Drive gear; 27. Top roller; 28. Sliding door glass; 29. Gasket; 30. Glass clip; 31. Lower roller; 32. Tension roller; 33. Drum with driven gear; 34. Power window housing; 35. Housing cover; 36. Lock lock button; 37. External door handle; 38. Leash of the lock switch; 39. External handle housing; 40. Lock switch; 41. The lever of the external drive of the lock; 42. External drive lever spring; 43. Ratchet; 44. Lock case; 45. Spring lock lever; 46. The lever of the internal drive of the lock; 47. Internal door handle; 48. Traction of the internal drive; 49. Thrust of the button of blocking of the lock; 50. Lever for blocking the lock; 51. Central roller; 52. Lock release roller; 53. Lock switch rod; 54. Ratchet spring; 55. Rotor; 56. Lock cracker; 57. Support washer; 58. Bushing of the central roller; 59. Intermediate rod of the internal drive; I. Seats; II. Skid front left seat; III. Power window front right door; IV. Front left door lock; V. Rear left door lock.

Front seats

The front seats are separate with individual adjustment of the position of the seat and backrest.

The seat slides consist of guides 6 and sliders 5 stamped from sheet steel. The sliders can move along the guides on two rollers 3 each. Two balls 4 are inserted into the channels between the walls of the sliders and guides on each side with an interference of up to 0.3 mm. The balls prevent the sled from moving up and to the sides. The handle 8 for moving the seat is rigidly connected to the latch, which, under the action of a spring, enters one of the grooves of the latch comb welded to the slide guide. When the handle 8 is pressed down, the latch is released and the seat can be moved to the desired position. The seat slides are attached to brackets welded to the body floor. The seat back has coarse and fine tilt adjustment.

The backrest tilt adjustment mechanism consists of a screw 7 with a handle and a rod, a spring 2, a backrest amplifier 1 and a latch welded to the front of the cushion frame 12. Screw 7 is screwed into the end of the rod. The threaded section of the screw has a cylindrical groove into which a cotter pin is inserted through the groove. The cotter pin prevents the propeller from completely turning out of the rod. On the screw between the handle and the thread there are annular grooves that engage with the teeth of the latch. If the screw handle is raised (coarse backrest adjustment), the screw disengages from the lock; spring 2 at the same time moves the screw with a rod relative to the latch back, and the backrest forward.

When turning the handle (fine adjustment) the screw is held in place by the latch, and the rod moves the seatback behind the reinforcement 1.

Backseat

The rear seat consists of a separate backrest and cushion. The pillow with two holes 9 is mounted on spikes welded to the floor cross member. The seat back in the upper part is fastened with two slats included in the brackets, which are welded to the rear shelf; at the bottom, the back is fastened with two tongues, which are welded to the wheel arches and bent onto the brackets of the lower corners of the back frame. A folding middle armrest is built into the back of the seat.

Power window door

The window regulator of the door is cable, fastened with three nuts on the inner panel of the door. Three rollers 27, 31 and 32, which cover the power window cable, are fixed on the brackets. Roller 32 tensions the cable. To do this, pre-tighten the tension roller bolt 32 with a nut and blow through a special device to displace them along the groove on the inner door panel. After tightening, the bolt is finally tightened.

The cable is wound on a drum 33, the ring gear of which is engaged with the gear 26. In the support 25 of the drive roller 22, a spring brake is placed coaxially with the gear 26, which prevents the glass from spontaneously lowering. On the vertical section of the cable, with the help of two bolts and a pressure plate, a clip 30 is attached, in which the sliding glass 28 is clamped through the gasket 29. The sliding glass is placed in the guide grooves, bolted to the door panel.

The window regulator handle 20 is attached to the splined end of the drive shaft 22 using a clamping bracket that fits into the groove of the handle and into the groove of the shaft. A plastic lining 21 is installed under the handle.

Door locks

Rotary door locks. The protrusions of the rotor 55, mounted on the central roller 51, when the door is closed, run into the latch tooth and turn the roller 51 with the ratchet 43. The protrusion of the external drive lever 41 under the action of the spring 42 stops the roller with the rotor by the ratchet teeth. The ratchet has two teeth that provide preliminary and complete locking of the lock.

When the door is opened, the outer handle 37 presses on the upper end of the outer drive lever 41, which releases the ratchet, and under the action of the compressed seal, the door opens. When opening the door with the inner handle 47, the action is transmitted through the rod 48 to the lever 46 of the internal drive, which, in turn, presses the lever 41, releases the ratchet, and the door opens.

The lock can be blocked with button 36 to prevent access to the passenger compartment from the outside. When the button 36 is pressed with the door closed, the rod 49 turns the lock lever 50 to a position in which the external drive lever 41 is blocked. The locked front door lock can be released by lifting the button 36 or pulling the handle 47, or the lock switch 40. When the switch key is turned, the leash 38 of the latter acts through the rod 53, the roller 52 on the lock lever 50 and unlocks the lock.

The locks of the rear doors, unlike the front ones, can be blocked both with the doors closed and with the doors open (the button can be pressed with the door open and then closed). The lock can only be unlocked by lifting the lock button. This ensures the safety of transporting passengers in the rear seat.

On the door locks next to the rotor 55 there is a special steel washer 57, which, when the door is closed, comes into contact with the latch nut 56, which is pressed by a spring. The retainer cracker selects the gap between the upper edge of the support washer and the retainer body and eliminates the vertical movement of the door when the vehicle is moving. In the event of a collision or overturning of the car, the support washer 57 simultaneously prevents the doors from spontaneously opening due to deformation of the door or body pillars. The support washer extends beyond the walls of the latch housing and prevents the door from moving. The retainer is bolted to the body pillars.