Open large image in new tab »

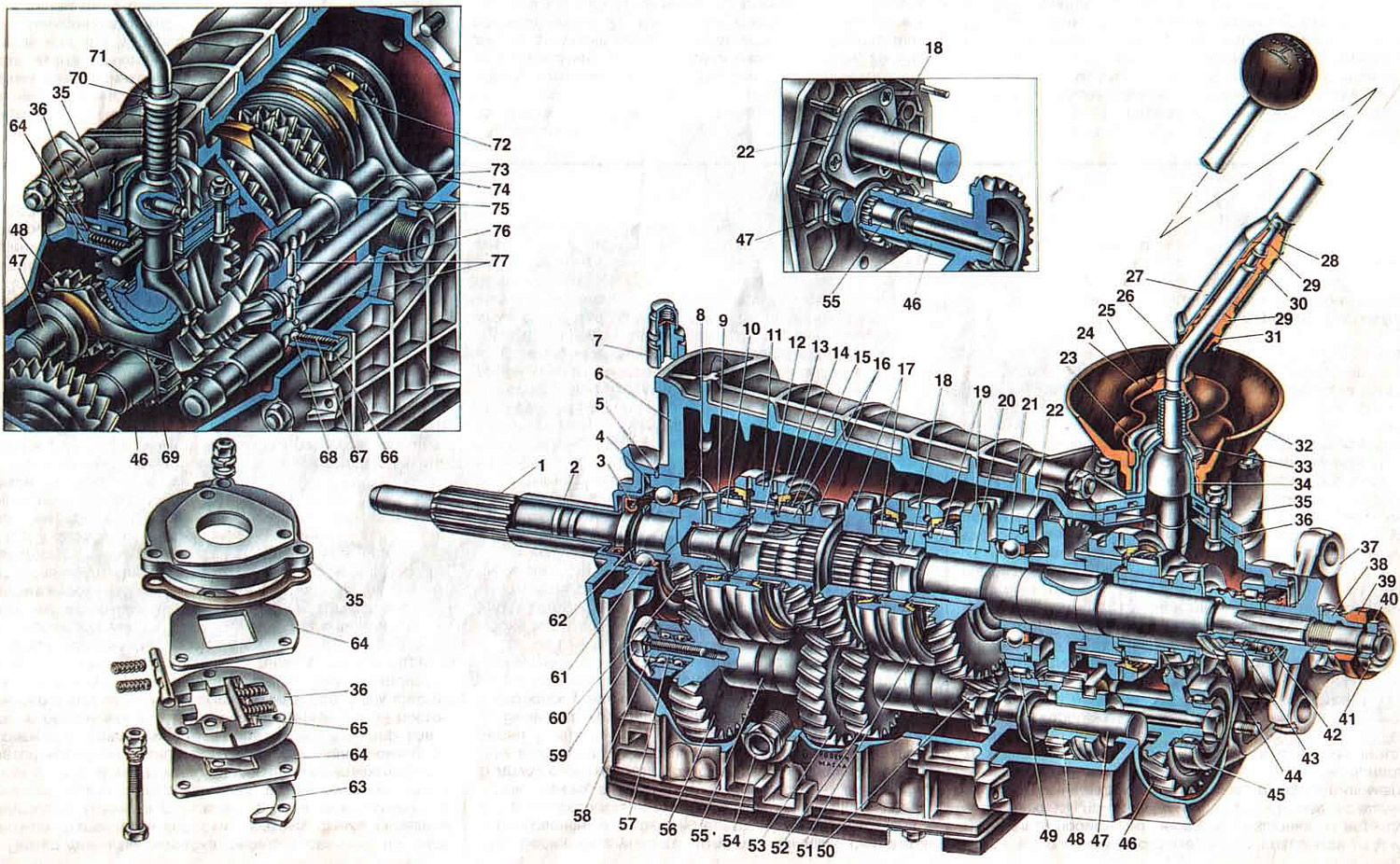

Pic. 17. Five-speed gearbox.

1. Primary shaft; 2. Gear box front cover; 3. Primary shaft seal; 4. Spring washer; 5. Bearing adjusting ring; 6. Gearbox housing; 7. Breather; 8. Needle bearing of the secondary shaft; 9. Thrust washer of the synchronizer spring; 10. Gear rim of the synchronizer of the 5th gear; 11. Sliding clutch of the synchronizer of III and IV gears; 12. Synchronizer coupling hub for III and IV gears; 13. Synchronizer retaining ring; 14. Blocking ring synchronizer; 15. Synchronizer spring; 16. Gear and ring gear of the synchronizer of the III gear; 17. Gear and ring gear synchronizer II gear; 18. Secondary shaft; 19. Gear and ring gear of the synchronizer of the 1st gear; 20. Bushing gear 1st gear; 21. Intermediate bearing of the secondary shaft; 22. Intermediate bearing lock plate; 23. Flange; 24. Protective cover; 25. Spring; 26. Gearshift lever; 27. Gear lever rod; 28. Elastic cushion damper; 29. Rubber damper bushing; 30. Damper spacer; 31. Locking sleeve damper; 32. Cuff; 33. Spherical washer; 34. Ball joint lever; 35. Gear lever housing; 36. Guide plate; 37. Flange of the flexible coupling of the driveline; 38. Nut; 39. Centering ring seal; 40. Centering ring; 41. Retaining ring; 42. Output shaft rear bearing seal; 43. Protective bearing of the secondary shaft; 44. Speedometer drive gear; 45. Gear block bearing; 46. Block gears V transmission and reverse; 47. The axis of the intermediate reverse gear; 48. Intermediate reverse gear; 49. Rear intermediate shaft bearing; 50. Gear wheel of the 1st gear of the intermediate shaft; 51. Sliding clutch synchronizer I and II gears; 52. Gear wheel of the second gear of the intermediate shaft; 53. Gear wheel of the III gear of the intermediate shaft; 54. Filler plug; 55. Intermediate shaft; 56. Gear wheel of constant engagement of the intermediate shaft; 57. Front intermediate shaft bearing; 58. Clamping washer intermediate shaft bearing; 59. Clamping washer bolt; 60. Gear wheel of constant engagement of the input shaft; 61. Rear input shaft bearing; 62. Stop wheel; 63. Reverse locking bracket; 64. Guide plate washers; 65. Guide bar; 66. Cover of clamps; 67. Spring retainers; 68. Retainer; 69. Fork of inclusion of V transfer and a backing; 70. Thrust washer; 71. Retaining ring; 72. Switching fork III and IV gears; 73. The rod of the fork of inclusion of I and II gears; 74. The rod of the fork of inclusion of III and IV gears; 75. Fork of inclusion of I and II transfers; 76. The rod of the fork of the inclusion of V gear and reverse; 77. Block crackers.

1. Primary shaft; 2. Gear box front cover; 3. Primary shaft seal; 4. Spring washer; 5. Bearing adjusting ring; 6. Gearbox housing; 7. Breather; 8. Needle bearing of the secondary shaft; 9. Thrust washer of the synchronizer spring; 10. Gear rim of the synchronizer of the 5th gear; 11. Sliding clutch of the synchronizer of III and IV gears; 12. Synchronizer coupling hub for III and IV gears; 13. Synchronizer retaining ring; 14. Blocking ring synchronizer; 15. Synchronizer spring; 16. Gear and ring gear of the synchronizer of the III gear; 17. Gear and ring gear synchronizer II gear; 18. Secondary shaft; 19. Gear and ring gear of the synchronizer of the 1st gear; 20. Bushing gear 1st gear; 21. Intermediate bearing of the secondary shaft; 22. Intermediate bearing lock plate; 23. Flange; 24. Protective cover; 25. Spring; 26. Gearshift lever; 27. Gear lever rod; 28. Elastic cushion damper; 29. Rubber damper bushing; 30. Damper spacer; 31. Locking sleeve damper; 32. Cuff; 33. Spherical washer; 34. Ball joint lever; 35. Gear lever housing; 36. Guide plate; 37. Flange of the flexible coupling of the driveline; 38. Nut; 39. Centering ring seal; 40. Centering ring; 41. Retaining ring; 42. Output shaft rear bearing seal; 43. Protective bearing of the secondary shaft; 44. Speedometer drive gear; 45. Gear block bearing; 46. Block gears V transmission and reverse; 47. The axis of the intermediate reverse gear; 48. Intermediate reverse gear; 49. Rear intermediate shaft bearing; 50. Gear wheel of the 1st gear of the intermediate shaft; 51. Sliding clutch synchronizer I and II gears; 52. Gear wheel of the second gear of the intermediate shaft; 53. Gear wheel of the III gear of the intermediate shaft; 54. Filler plug; 55. Intermediate shaft; 56. Gear wheel of constant engagement of the intermediate shaft; 57. Front intermediate shaft bearing; 58. Clamping washer intermediate shaft bearing; 59. Clamping washer bolt; 60. Gear wheel of constant engagement of the input shaft; 61. Rear input shaft bearing; 62. Stop wheel; 63. Reverse locking bracket; 64. Guide plate washers; 65. Guide bar; 66. Cover of clamps; 67. Spring retainers; 68. Retainer; 69. Fork of inclusion of V transfer and a backing; 70. Thrust washer; 71. Retaining ring; 72. Switching fork III and IV gears; 73. The rod of the fork of inclusion of I and II gears; 74. The rod of the fork of inclusion of III and IV gears; 75. Fork of inclusion of I and II transfers; 76. The rod of the fork of the inclusion of V gear and reverse; 77. Block crackers.

On VAZ-21065 vehicles, and on request on a number of VAZ-2106 vehicles, a five-speed gearbox is installed. It was created on the basis of a four-stage box and differs in appearance by the shape of the back cover, in the cavity of which the fifth stage is located at the end of the driven shaft. The introduction of an additional fifth gear has expanded the range of vehicle speeds, due to which the engine is operated in the most economical modes, and engine operating conditions are also improved. This, in turn, increases the durability of its work. The gear ratios of the same gears for the five- and four-speed gearboxes are the same. The gear ratio of the fifth gear is 0.82.

Due to the fact that the five-speed gearbox is based on a four-speed gearbox, many of its parts have the same design and are interchangeable. The gearbox is also three-shaft, that is, it consists of primary 1, secondary 18 and intermediate 55 shafts. The input shaft is identical to the four-speed box shaft. The output shaft is distinguished by its rear part, on which the details of the fifth stage are located. The intermediate shaft differs in that in the rear end it has a threaded hole for the bolt of fastening the block 46 of the fifth gear and reverse gears. Driven gears 16, 17, 19 of the third, second and first gears, synchronizer parts, shaft bearings are unified with the same parts of the four-speed gearbox. Thus, the design of the parts located in the crankcase cavity of the box is the same with a four-stage box (see fig. 15).

Details of the fifth gear and reverse are located in the cavity of the rear cover. Together with driven gear 12 (see fig. 18) reverse gear on the driven shaft 2, the hub 13 of the clutch 14 of the fifth gear synchronizer is attached with one key. Behind the hub 13 there is a thrust washer and a bushing 18, on which the gear 17 of the fifth gear rotates. Between the gear sleeve 17 and the drive gear 20 of the speedometer drive, an oil slinger washer 19 is clamped. It reduces the ejection of oil towards the stuffing box 42 (see fig. 17), improving working conditions. The rear end of the secondary shaft rotates on a cylindrical roller bearing 43, because. the load on the rear end of the shaft has increased. A flange 37 of an elastic coupling is attached to the splines of the shaft. All parts located on the secondary shaft are pressed with nut 38, which is fixed with a lock washer. A rubber seal 39 is located on the cylindrical belt of the nut, and a centering ring 40 and its retaining ring are located at the end of the shaft.

On the splines of the intermediate shaft 55, the block 46 of the gears of the fifth gear and reverse is fastened with a coupling bolt. The rear support for the gear unit is a cylindrical roller bearing 45. The gear unit has two rims. The large crown is in constant engagement with the fifth gear driven gear. With a small crown, the intermediate gear 48 engages when the reverse gear is engaged. The intermediate gear 48 is located on the axis 47, which is mounted in the baffle of the crankcase of the box with a nut with a Belleville spring washer. The other end of the axle rests in the socket of the rear cover.

The gearshift drive also differs slightly from the four-speed gearbox drive. The design of the rod 76 and the fork 69 of the reverse and fifth gears has been changed. A double fork 69 is attached to the rod 76 with a locking bolt - one enters the groove of the intermediate reverse gear 48, the other into the annular groove of the fifth gear synchronizer clutch. Thus, when moving the rod 76, the same fork will include one or another gear. In this regard, in the rod 76, as well as on other rods, there are three sockets for the balls of the retainers. Fork 69 has a groove into which the lower end of the gear lever enters. At the end of the rod 76, a head is fixed with a locking bolt, on which a flat is made, with which the head acts on the rod (ball) reversing light switch. In the future, when changing the design of the drive, it is planned, together with the head of the rod, to produce a lug with a groove for the lower end of the gear lever, removing this lug from the fork 69.

A new gear selection mechanism has been introduced into the gear shift drive. It blocks accidental engagement of reverse gear when engaging fifth gear. The gear selection mechanism consists of a guide plate 36 of the lever, the upper and lower washers 64 of the guide plate, the housing 35 of the gear lever, the reverse locking bracket 63. The listed parts are tightened with three bolts, with which the selector mechanism is attached to the socket of the rear cover of the gearbox. In the grooves of the guide plate 36, spring-loaded guide bars 65 are installed, between which the lower end of the gear lever is clamped. Under the action of the springs of the guide plates, the gear lever is set to a neutral position, in which the end of the lever is located in the groove of the head of the rod 74 for engaging III and IV gears.

When the V gear is turned off, if the lever crosses the line of the neutral position, the protrusion of the lever rests against the bent tab of the locking bracket 63 and further movement of the lever towards the reverse gear stops. This eliminates the accidental engagement of reverse gear while the car is moving and damage to the gearbox parts. To engage reverse gear, press the lever down to compress its spring. In this case, the ledge of the lever will fall below the petal of the locking bracket 63, and you can move the gear lever back until the reverse gear is fully engaged.