Open large image in new tab »

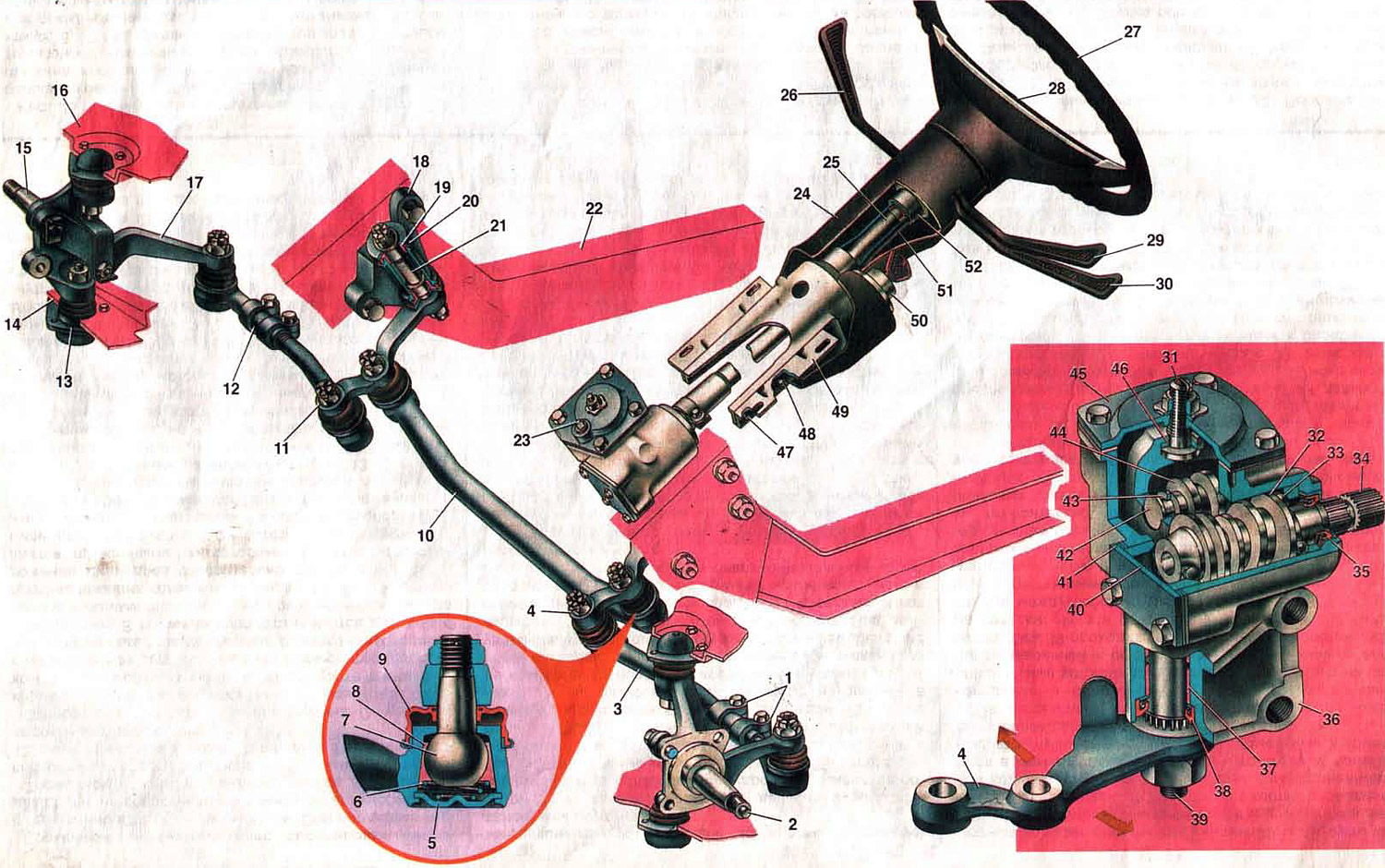

Pic. 24. Steering.

1. Coupling collar of lateral draft; 2. Left knuckle; 3. Internal tip of the side rod; 4. Bipod; 5. Support washer of a spring of an insert of a spherical finger; 6. Liner spring; 7. Ball pin; 8. Ball pin insert; 9. Protective cap of the ball pin; 10. Medium thrust steering gear; 11. Pendulum lever; 1.2. Adjusting coupling of lateral draft; 13. Lower ball joint of the front suspension; 14, Front suspension lower arm; 15. Right knuckle; 16. Upper suspension arm; 17. The lever of the right rotary fist; 18. Pendulum arm bracket; 19. Bushing axis pendulum lever; 20. O-ring bushing axle pendulum lever; 21. The axis of the pendulum lever; 22. Right side member of the body; 23. Oil filler plug; 24. Facing casing of the steering shaft; 25. Steering shaft; 26. The lever of the switch of a screen wiper and washer; 27. Steering wheel 28. Horn switch; 29. The lever of the switch of indexes of turn '; 30. Headlight switch lever; 31. Adjusting screw; 32. Worm; 33. Worm bearing; 34. Worm shaft; 35. Oil seal; 36. Steering gear housing; 37. Bipod shaft bushing; 38. Bipod shaft seal; 39. Bipod shaft; 40. The lower cover of the crankcase of the steering mechanism; 43. Shims; 44. Bipod shaft roller; 45. Top cover of the crankcase of the steering mechanism; 46. Adjustment screw plate; 47. Rivet fastening the plate and flange of the bracket; 48. Bolt for fastening the plate and flange of the bracket; 49. An arm of fastening of a shaft of a steering; 50. Ignition switch; 51. Pipe of the upper support of the steering shaft; 52. Pipe flange of the upper support of the steering shaft.

1. Coupling collar of lateral draft; 2. Left knuckle; 3. Internal tip of the side rod; 4. Bipod; 5. Support washer of a spring of an insert of a spherical finger; 6. Liner spring; 7. Ball pin; 8. Ball pin insert; 9. Protective cap of the ball pin; 10. Medium thrust steering gear; 11. Pendulum lever; 1.2. Adjusting coupling of lateral draft; 13. Lower ball joint of the front suspension; 14, Front suspension lower arm; 15. Right knuckle; 16. Upper suspension arm; 17. The lever of the right rotary fist; 18. Pendulum arm bracket; 19. Bushing axis pendulum lever; 20. O-ring bushing axle pendulum lever; 21. The axis of the pendulum lever; 22. Right side member of the body; 23. Oil filler plug; 24. Facing casing of the steering shaft; 25. Steering shaft; 26. The lever of the switch of a screen wiper and washer; 27. Steering wheel 28. Horn switch; 29. The lever of the switch of indexes of turn '; 30. Headlight switch lever; 31. Adjusting screw; 32. Worm; 33. Worm bearing; 34. Worm shaft; 35. Oil seal; 36. Steering gear housing; 37. Bipod shaft bushing; 38. Bipod shaft seal; 39. Bipod shaft; 40. The lower cover of the crankcase of the steering mechanism; 43. Shims; 44. Bipod shaft roller; 45. Top cover of the crankcase of the steering mechanism; 46. Adjustment screw plate; 47. Rivet fastening the plate and flange of the bracket; 48. Bolt for fastening the plate and flange of the bracket; 49. An arm of fastening of a shaft of a steering; 50. Ignition switch; 51. Pipe of the upper support of the steering shaft; 52. Pipe flange of the upper support of the steering shaft.

The steering consists of a worm gear, a steering wheel 27, a steering shaft 25 and a steering gear. The worm gearbox is located in an aluminum crankcase 36, which is attached to the left side member of the body with three bolts with self-locking nuts. Adjusting shims are installed between the crankcase of the steering mechanism and the side member, which achieve the alignment of the worm shaft and the steering shaft. For the same purpose, two holes in the crankcase for mounting bolts are made oval.

A worm 32 is installed in the crankcase on two angular contact bearings 33. The bearings do not have inner rings. Their role is played by treadmills made at the ends of the worm. The clearance in the worm bearings is regulated by gaskets 41 installed under the bottom cover 40. At the outlet of the crankcase, the worm shaft 34 is sealed with an oil seal 35. An annular groove is made on the splined part of the worm shaft for a coupling bolt when the worm shaft is connected to the tip of the steering shaft. In engagement with the worm is a double-ridge roller 44, which rotates on an axle 42 in a double-row needle bearing. The ends of the axle, after being pressed into the holes of the shaft lugs 39, are riveted using electrical heating, i.e. this connection is one-piece. Thrust washers 43 are installed between the ends of the roller and the groove of the bipod shaft, which limit the axial movement of the roller on the axis.

The bipod shaft with a cylindrical polished part is installed in two bronze bushings 37 and sealed with an oil seal 38 at the outlet of the crankcase. Bipod 4 is mounted on the conical splines of the bipod shaft in one specific position, thanks to the double spline on the shaft and the double cavity in the bipod hole.

The gearing of the worm pair is made with a shift of the axes of the roller and the worm by 5.5 mm, which allows you to adjust the backlash-free engagement of the roller with the worm as they wear out. This is ensured by axial displacement of the bipod shaft using the adjusting screw 31. The head of the screw enters the T-shaped cutout of the bipod shaft together with the plate 46, which ensures the desired fit of the screw head. The adjusting screw 31 is screwed into the top cover 45, secured against turning with a washer and tightened with a lock nut. When the adjusting screw is screwed into the cover, the bipod shaft is lowered, and the gap in the engagement of the roller with the worm is selected.

The parts of the worm gear are lubricated with TAD-17i oil, which is poured through the hole closed with plug 23, the filling capacity is 0.215 liters.

The steering wheel is made of plastic reinforced with a steel frame. Splines with a double cavity are cut in the steering wheel hub, and double splines on the shaft 25, which ensures that the wheel is connected to the shaft in only one position. The steering wheel is attached to the shaft with a nut, which, after tightening, is punched out at one point. The upper part of the steering shaft rests on a sleeve pressed into the upper support pipe. The lower end of the pipe is fastened with a coupling bolt to the bracket 49. At the upper end of the pipe, the switch for headlights, direction indicators, wiper and windshield washer is attached with a clamp. The ignition switch 50 is fixed with two screws in the socket of the bracket 49. Bracket 49 is attached to the body panel bracket with four bolts. The mounting bolt holes in the bracket are oval shaped for a more precise connection (centering) steering shafts and worm. The lower part of the shaft 25 splined tip is connected to the shaft 34 of the worm and secured with a coupling bolt. In the area of fastening of the ignition switch on the steering shaft, a ring is welded into the groove of which the locking rod of the anti-theft device of the ignition switch enters. The steering shaft is closed by a facing casing 24, consisting of the upper and lower parts, interconnected by screws.

The steering drive includes: bipod 4, middle 10 and side rods 3, pendulum lever 11, swivel levers 17. These parts are interconnected by ball joints. The bipod is connected to the middle and side rods. The bipod stop limits the angle of rotation of the front wheels.

The middle rod 10 is one-piece, at the ends it has sockets for accommodating parts of ball joints. Lateral traction 3 composite. Each of them consists of two tips connected to each other by a threaded adjusting sleeve 12. The sleeve is fixed on the tips with two clamps 1. With this design of the side rods, their length can be changed, which is necessary to control the toe of the steered wheels. The outer tips of the side rods are pivotally connected to the swivel arms 17, which are bolted to the steering knuckles. The inner tip of the right side rod is pivotally connected to the pendulum lever, and the tip of the left rod is connected to the bipod. All ball joints are the same.

The ball joint of the rod consists of a steel pin 7, the spherical head of which rests on a split conical insert 8, made of plastic with high anti-seize properties. The conical spring 6, pressing the insert against the spherical head of the pin 7, automatically maintains a backlash-free connection between them. From below, in the socket of the tip, a washer 5 is rolled, which is a support for the spring. The conical part of the pin goes into the conical hole of the swing arm (bipod or pendulum arm) and fastened with a castellated nut, fixed with a cotter pin. During assembly, the hinges are filled with SRB-4 grease and sealed: from below with a support washer 5, from above with a reinforced cap 9. Replenishment or replacement of grease is carried out only when the car is being repaired.

The pendulum arm bracket is attached to the inside of the right side member with two bolts with self-locking nuts. The bracket is cast from aluminum alloy. In its through groove there are two plastic bushings 19, on which the axis 21 of the pendulum lever rotates. Washers are pressed to the ends of the bushings. The upper washer is mounted on the flats of the axle and is tightened with a castellated nut with a moment that ensures the rotation of the lever with a force of 10-20 N (1-2 kgf), attached at its end. The lower washer is pressed against the sleeve by a self-locking nut with a torque of 106 Nm (10 kgf·m). The pendulum lever 11 is fixed on the axis with the same nut. Rubber sealing rings 20 are installed between the end surfaces of the washers and the body of the pendulum lever bracket. During assembly, the cavity between the bushings is filled with Litol-24 grease. The bushings themselves are lubricated with the same grease.