Open large image in new tab »

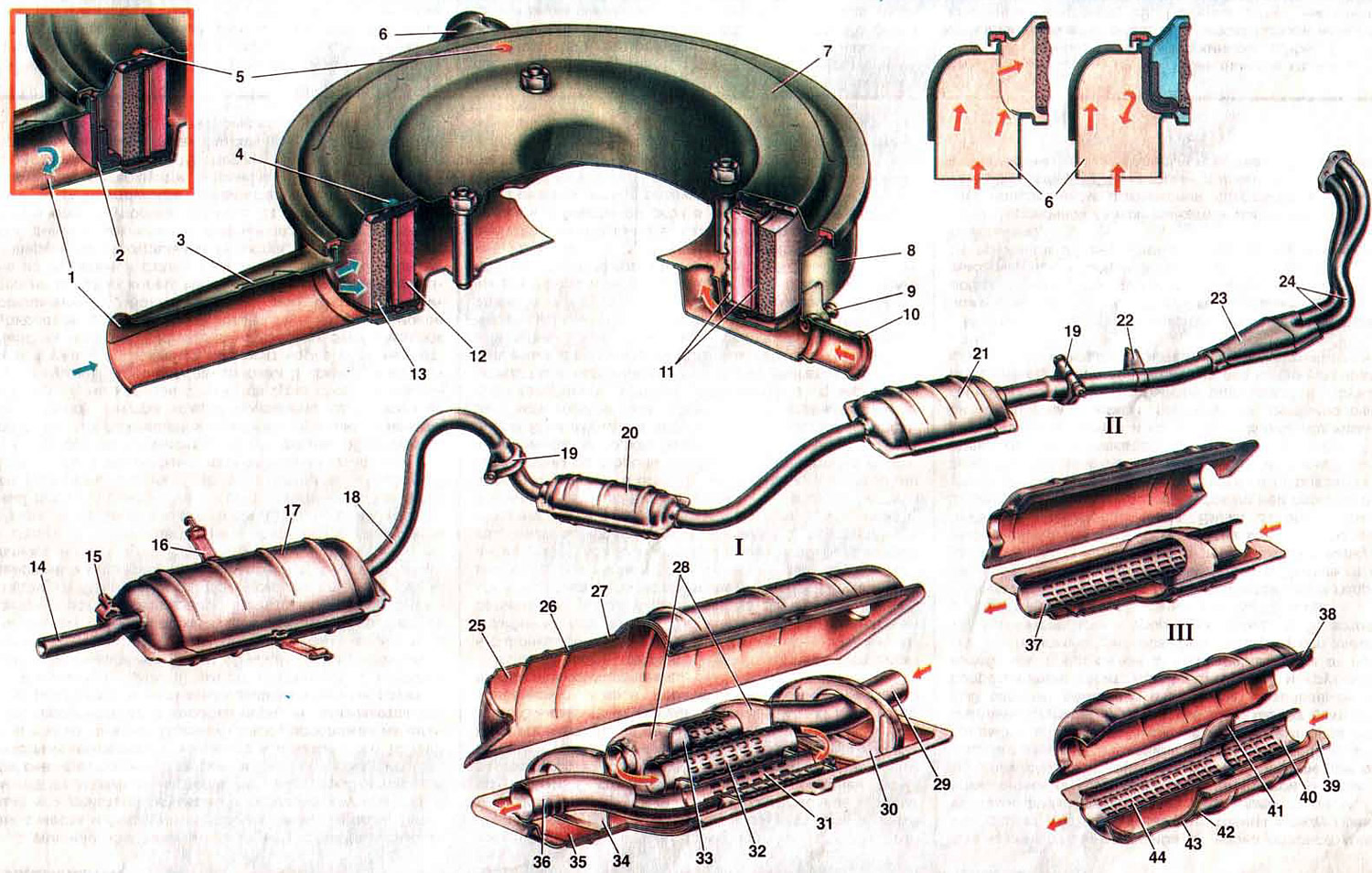

Pic. 12. Air filter, mufflers. 1. Cold air intake; 2. Partition blocking air access to the filter; 3. Arrow for setting the filter cover according to the marks for winter and summer operating modes; 4. The label is blue for setting the summer mode of operation; 5. Red label for setting for winter operation; 6. Warm air intake pipe from the exhaust manifold; 7. Filter cover; 8. Filter housing; 9. Branch pipe for suction of crankcase gases into the spool device of the carburetor; 10. Collector of exhaust ventilation of the engine crankcase; 11. Perforated shell filter element; 12. Cardboard filter element; 13. Filter element precleaner; 14. Outlet pipe; 15. Cushion suspension exhaust pipe; 16. Silencer suspension belt; 17. Main muffler; 18. Front pipe of the main muffler; 19. Clamps; 20. Rear additional muffler; 21. Front additional muffler; 22. A collar of fastening of a reception pipe to a transmission; 23. Gas receiver; 24. Downpipe; 25. Upper semi-body of the main muffler; 26. Thermal insulation of the main muffler; 27. The casing of the main muffler; 28. Medium partitions; 29. Inlet pipe; 30. Front baffle; 31. Perforation of the exhaust pipe; 32. Inner perforated pipe; 33. Casing inlet perforated pipe; 34. Rear baffle; 35. The lower semi-body of the main muffler; 36. Outlet pipe; 37. Perforated pipe front additional muffler; 38. The upper half-case of the rear additional muffler; 39. The lower half-case of the rear additional muffler; 40. Front perforated pipe; 41. Deaf partition; 42. Rear additional muffler cover; 43. Thermal insulation of the rear additional muffler; 44. Rear perforated pipe; I. Main silencer. II. Front additional muffler; III. Rear additional muffler.

Air filter

The air filter cleans the air entering the carburetor from mechanical impurities. The engine is equipped with a single-stage dry-type air filter with a replaceable filter element with a pre-cleaner. The air filter has seasonal adjustment of intake air temperature.

The air filter housing 8 is stamped from a steel sheet. The filter housing is mounted on the carburetor flange with four studs and fastened with self-locking nuts. On the carburetor, the filter is sealed with a rubber gasket. From above, the filter housing is closed with a cover 7 with a rubber seal. The cover is fastened with three nuts screwed onto the axles with remote ledges. The body and cover of the filter are painted with black enamel.

The filter element is made of a special filter cardboard 12 inserted into metal perforated shells 11. A filter element 13 made of synthetic wool is put on the outside for preliminary air purification (precleaner), increasing the dust capacity of the filter.

The filter housing has an air intake 1 of cold air and a branch pipe 6 of the intake of heated air from the zone of the exhaust manifold of exhaust gases. Branch pipe 6 is connected by a corrugated hose to the warm air intake.

From the bottom side, a crankcase exhaust ventilation manifold 10 is welded to the air filter housing, which is connected to the space behind the filter element. The branch pipe 9 for crankcase gases is connected by a hose to the spool of the carburetor.

When the engine is running, air enters the air filter housing through the cold air intake 1 from the engine compartment or through the warm air intake from the exhaust manifold area through a corrugated hose and pipe 6.

To seasonally adjust the temperature of the intake air, the air filter cover 7 has a seasonal baffle 2 on one side, blocking the access of air from the air intake 1 or pipe 6.

When installing the air filter, the cover must be positioned correctly. In summer, the cover is placed so that the blue mark 4 "summer" coincided with the black arrow 33 on the air intake, and in winter - so that the red mark 5 is opposite the arrow 3 "winter" on the filter cover. An air filter is installed on VAZ-21065 vehicles, which is interchangeable with the filter of a VAZ-2105 vehicle.

Intake pipe

The inlet pipe is cast iron, mounted on the cylinder head studs through two sealing metal-asbestos or ferronite gaskets common with the exhaust manifold.

The inlet pipe has a platform for installing a carburetor and four channels for supplying the working mixture to the engine cylinders. The pipe has a jacket for heating the working mixture, which is connected by channels to the jacket for cooling the cylinder head. The liquid is drained from the intake pipe heating jacket through a hose and tube to the engine cooling system pump.

Gasoline condensate formed on a cold engine drains out through a drain pipe pressed into the intake pipe and connected to the intake chamber of the pipe. To eliminate noticeable lean mixture at idle due to air leaks, the drain tube has an outlet with a diameter of (0,8±0,1) mm.

Exhaust gas outlet

Exhaust gases are released through the exhaust manifold, downpipe 24, front 21 and rear 20 additional mufflers and the main muffler 17. The downpipe and mufflers are non-separable, they are interconnected by pushing the pipes one into the other and are fixed with coupling clamps 19. Moreover, one of the connected pipes has flared end with two longitudinal diametrically located slots. When assembling, it is necessary to completely cover the said slots with the inserted pipe.

The exhaust manifold is cast iron, has four pipes for exhaust gases from four cylinders. The manifold is studded to the cylinder head through sealing metal-asbestos or ferronite seals. The collector in the lower part has a flange to which the exhaust pipe of the mufflers is attached.

Downpipe

The downpipe consists of a flange, two pipes, a gas inlet 23, welded from two stamped halves, closed on both sides with asbestos heat-insulating gaskets and thin-walled protective casings. The exhaust pipe is studded to the exhaust manifold with four brass nuts, as well as to a bracket attached to the gearbox with a clamp 22. A sealing gasket made of asbestos sheet reinforced with steel tape is installed between the exhaust pipe and the manifold. Since 1988, the gasket has been made from elastomer. Gasket and nuts are disposable.

Silencers consist of two stamped half-shells, welded together. Perforated pipes and partitions are placed inside the mufflers, forming chambers, each of which suppresses the noise of a certain frequency range.

The main muffler 17 has two stamped half-shells 25 and 35, perforated pipes and baffles 28, 30 and 34, of which two baffles are made deaf. Asbestos sheet or other insulating material is laid under the casings of the upper and lower half-hulls for thermal insulation and noise reduction.

The main muffler shells and internal perforated pipes are made of stainless steel to improve corrosion resistance. The exhaust pipe 14 VAZ-2106 may have a decorative gas outlet made of stainless steel.

The front and rear additional mufflers, unlike the main one, have only one blank partition each; their perforated pipes are located coaxially and have throttling diaphragms, as in the first produced car models. Installing diaphragms when repairing a car is not recommended due to the additional loss of engine power for exhaust gases.

Mufflers with pipes assemblies are attached to the floor of the body with two rubber straps 16 for the body of the main muffler and a rubber cushion for the exhaust pipe 14.