Fuel tank with a volume of 39 liters, welded from two halves, stamped from leaded sheet steel, painted with black enamel on the outside. The tank is located in the trunk on the right side in the direction of the car and is attached to the body with a clamp tightened with a bolt. The filler neck of the tank is led into a niche on the right rear fender and closed with a screw plug. For ventilation, the fuel tank has a hose leading into the niche of the filler neck. On top of the tank, a sensor for the level indicator and fuel reserve is installed through the sealing gasket. From the sensor on the instrument panel displays data on the remaining fuel in the tank. When the remaining fuel is 4.0-6.5 liters, a control lamp lights up on the instrument panel.

Fuel lines made of galvanized steel tubes and fixed from below to the bottom of the body with holders. The parts of the fuel system are interconnected by rubber hoses, secured with clamps.

Fuel pump - diaphragm type, with a mechanical drive and a manual pumping lever. The pump is located on the left side of the cylinder block and is fixed through a heat-insulating spacer and gaskets on two studs with nuts. The pump is driven through a pusher from an eccentric on the auxiliary drive shaft or from a manual pumping lever. The pump capacity is not less than 60 l/h at a pumping frequency of 2000 cycles per minute. The pressure created by the pump is in the range of 0.2-0.3 kgf / cm². The pump consists of a lower housing with drive levers, an upper housing with inlet and discharge valves, a diaphragm assembly and a cover. The diaphragm assembly has two upper working and one lower (safety) diaphragms mounted on the stem. Between the workers and the safety gasket, inner and outer spacers are installed. In order to prevent fuel from entering the crankcase in case of damage to the working diaphragms of the fuel pump, a hole for draining the fuel is made in the outer gasket.

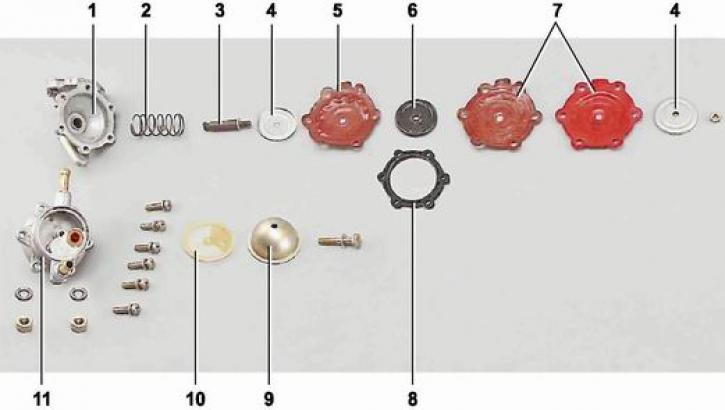

Fuel Pump Details: 1 - lower body; 2 - return spring; 3 - stock; 4 - plate diaphragm assembly; 5 - safety diaphragm; 6 - internal spacer; 7 - working diaphragms; 8 - outer spacer; 9 - pump cover; 10 - mesh filter; 11 - upper body

Air filter - dry, with a replaceable filter element that cleans the air entering the carburetor. The filter housing is mounted on the carburetor cover through a rubber gasket with spacer bushings on four studs and fastened with self-locking nuts. The top of the filter housing is closed with a cover with a rubber seal. Air enters the air filter housing through the cold air intake or through a pipe connected by a corrugated hose to the warm air intake from the exhaust manifold area. The air flow through the air intake or branch pipe is blocked by a partition A, attached to the lid.

Depending on the season, the lid is rearranged to the desired position (in summer the flow of warm air is blocked, in winter - cold).

The air filter housing is connected by a crankcase gas supply hose to the oil separator cover of the crankcase ventilation exhaust system. A flame arrester is installed in the crankcase gas supply hose.

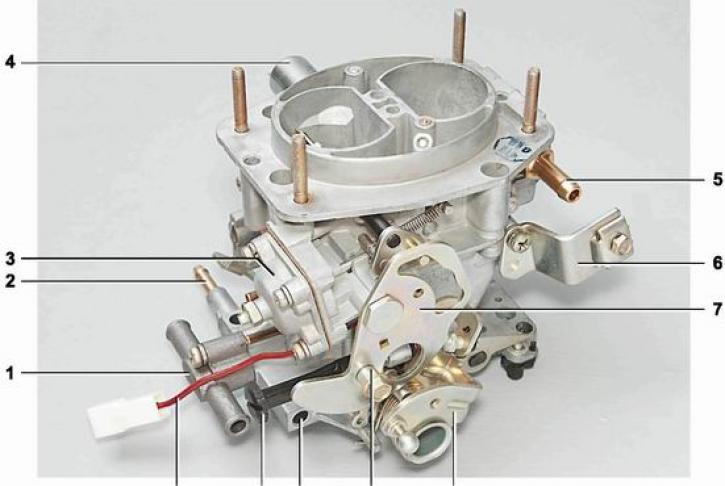

On vehicles with engines of models 2106 and 2103, carburetor 2107-1107010-20. On vehicles with a model 21011 engine, carburetor 2105-1107010-20 without solenoid shut-off valve.

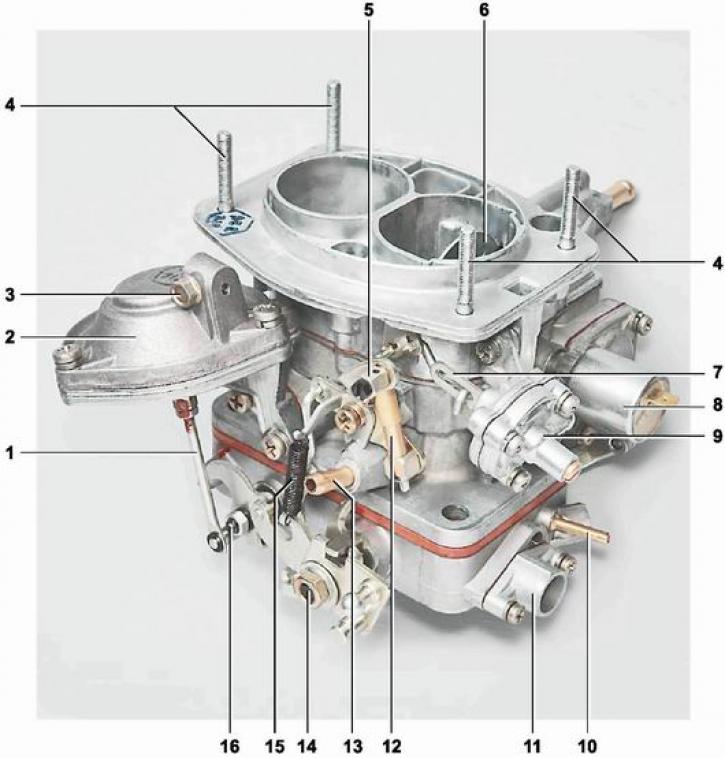

Carburetor 2107-1107010-20: 1 - thrust of the pneumatic actuator of the throttle valve of the secondary chamber; 2 - pneumatic actuator of the throttle valve of the secondary chamber; 3 - a bolt of fastening of a cover of draft of a drive of an air damper; 4 - studs for fastening the air filter housing; 5 - coupling with a screw for fastening the air damper drive rod; 6 - air damper; 7 - diaphragm rod of the starting device; 8 - solenoid valve; 9 - starting device; 10 - fitting for supplying vacuum to the vacuum regulator of the ignition distributor; 11 - quality screw holder; 12 - telescopic rod; 13 - branch pipe for crankcase gases; 14 - axis of the throttle valve of the primary chamber; 15 - return spring for blocking the opening of the damper of the secondary chamber; 16 - axis of the throttle valve of the secondary chamber

Carburetor emulsion type, two-chamber, with a falling stream. The combustible mixture is formed from the air entering through the air filter and the fuel supplied by the pump. This ensures uninterrupted supply of a combustible mixture of optimal composition in all engine operating modes. The prepared mixture is sucked through the inlet pipeline into the engine cylinders. The carburetor consists of three body parts: a cover, a carburetor body and a throttle body.

The carburetor is mounted on four intake pipe studs. In the carburetor cover there are inlet mouths of the primary and secondary mixing chambers, a fuel supply fitting from the fuel pump, fuel and air channels. A fuel supply needle valve and a float are also fixed on the cover, providing the necessary fuel level in the float chamber. The carburetor body has large diffusers and a float chamber.

Air and fuel channels are made in the carburetor body, air and fuel jets, an accelerator pump sprayer and an electromagnetic shut-off valve are installed. The solenoid valve shuts off the fuel supply through the idle system when the ignition is turned off.

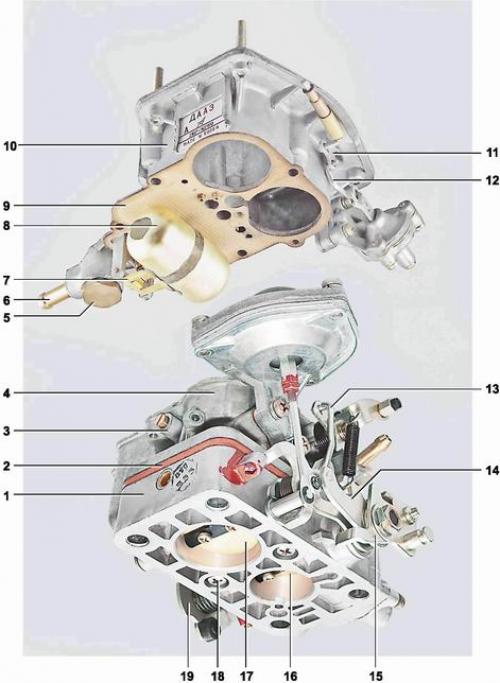

Carb cover and body 2107-1107010-20: 1 - throttle body; 2 - heat-insulating spacer; 3 - housing of the fuel jet of the transition system of the secondary chamber; 4 - carburetor body; 5 - plug of the carburetor fuel filter; 6 - fuel fitting; 7 - needle valve body; 8 - float; 9 - gasket; 10 - carburetor cover; 11 - air damper lever; 12 - rod connecting the air damper lever with the diaphragm rod of the starting device; 13 - thrust connection of the throttle valve with the drive of the starting device; 14 - lever limiting the opening of the throttle valve of the secondary chamber; 15 - throttle actuator lever; 16 - throttle valve of the primary chamber; 17 - throttle valve of the secondary chamber; 18 - screw for fastening the throttle body; 19 - accelerator pump drive cam

The accelerator pump provides an additional portion of fuel to the primary mixing chamber when the pedal is pressed sharply "gas". The diaphragm type pump is made in the tide of the body and is closed with a lid fixed with four screws. The diaphragm of the pump is moved by a lever. To ensure a smooth ride and, accordingly, a smooth and long injection, a damping spring is installed in the telescopic cup of the diaphragm. The accelerator pump lever is driven by a cam mounted on the throttle valve axle of the primary chamber.

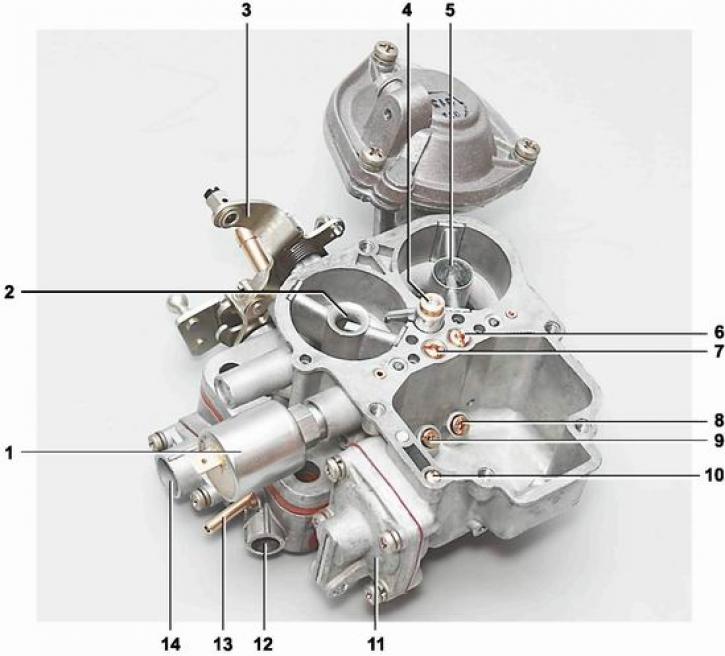

Carburetor body 2107-1107010-20: 1 - solenoid valve; 2 - small diffuser of the primary chamber; 3 - three-arm lever; 4 - accelerator pump sprayer; 5 - small diffuser of the secondary chamber; 6 - main air jet of the secondary chamber; 7 - main air jet of the primary chamber; 8 - main fuel jet of the secondary chamber; 9 - main fuel jet of the primary chamber; 10 - adjusting screw for fuel supply by the accelerator pump; 11 - accelerator pump cover; 12 - composition adjusting screw (quality) idle mixtures; 13 - fitting for supplying vacuum to the vacuum regulator of the ignition distributor; 14 - adjusting screw for the amount of idle mixture

From below, the throttle body is attached to the carburetor body with two screws. In it, rotary throttle valves are installed on the axles in the primary and secondary mixing chambers. The drive of the throttle valve of the primary chamber is carried out mechanically through a system of adjustable rods from the pedal "gas". The drive of the throttle valve of the secondary chamber is pneumatic. The drive housing, with a diaphragm and a return spring, is fixed to the carburetor body with two screws. The drive rod is pivotally connected to the lever on the axis of the throttle valve of the secondary chamber. The pneumatic drive begins to open it when the throttle valve of the primary chamber is deflected by an angle of more than 48°and a vacuum is created in the mixing chambers sufficient to open the damper.

To start and operate the engine when warming up, the carburetor has a starting device and an air damper. The air damper is mounted on an axis in the inlet neck of the primary chamber of the carburetor cover. The damper is driven from the driver's seat by a cable from the control handle. The body of the starting device is fastened with two screws to the carburetor cover. The diaphragm rod of the starter drive is connected by a rod to the air damper lever. The starting device cavity is connected by an air channel to the primary mixing chamber. When the engine starts, a vacuum is created in the cavity. The diaphragm rod depresses the return spring, acts on the thrust and slightly opens the air damper. Idling adjustment is carried out by the composition screws (quality) and the amount of the mixture.

Carburetor 21053-1107010: 1 - carburetor heating block; 2 - fitting for supplying crankcase gases; 3 - starter cover; 4 - solenoid valve; 5 - fuel supply pipe; 6 - bracket for fastening the shell of the draft of the air damper drive; 7 - air damper control lever; 8 - throttle control lever; 9 - bushing for fastening the air damper drive rod; 10 - composition adjusting screw (quality) idle mixtures; 11 - adjusting screw for the amount of idle mixture; 12 - electric wire of the EPHH limit switch

On a car with a contactless ignition system, it is installed carburetor 21053-1107010, equipped with forced idle economizer system (EPHH). The EPHX system includes a limit switch mounted on the idle mixture amount adjusting screw, a solenoid valve, an electronic control unit (see "Electrical circuits"). This system cuts off the fuel supply through the idle system at engine over idle (with the pedal released "gas" and engine speed over 1900 rpm).