To check, we prepare from a dense material (cardboard) two templates with a width of 6.5 + 0.25 mm and 14 + 0.5 mm.

Execution sequence

1. We prepare the car for work (see "Vehicle preparation for maintenance and repair").

2. Remove the carburetor cover (see "Carburetor cover - removal and disassembly").

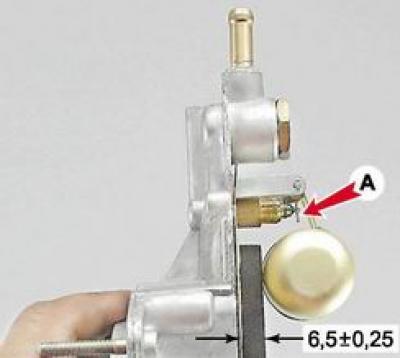

3. The maximum fuel level in the float chamber is determined by the moment the fuel supply hole is closed by the needle valve located in the valve seat. We set the cover in a vertical position so that the float tongue touches the spring-loaded valve ball, but at the same time its spring is not compressed. Using a template, we check the distance between the float and the gasket adjacent to the carburetor cover.

This distance should be within 6.5 + 0.25 mm. If the distance does not correspond to the specified one, then we adjust it by bending the tongue A needle valve mounts.

4. The maximum opening of the needle valve is determined by the stroke of the float. With the float retracted to the maximum with a template, we check the distance between the float and the gasket adjacent to the carburetor cover.

This distance should be 14 + 0.5 mm.

5. If necessary, bend the stop on the float bracket.

With correctly set extreme positions of the float, its stroke is 8 + 0.25 mm.

Installation

Install the carburetor cover on the body (see "Carburetor cover - removal and disassembly").