1. Remove the driveline (see "Cardan transmission - removal and installation").

2. We clean the shafts and hinges from dirt, wash them with water and detergent.

3. We apply marks with a center punch or paint (one side of the shaft) mutual arrangement of forks of universal joints in order to avoid imbalance of the universal joint.

Dismantling the universal joint

On a car with a high mileage, it is recommended to pre-knock through a suitable drift (socket head or old piston pin) the ends of the retaining rings and apply penetrating liquid to them.

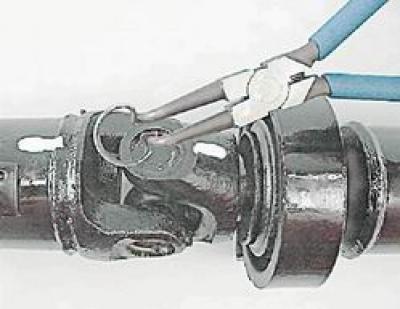

1. Using circlip pliers, remove the four rings.

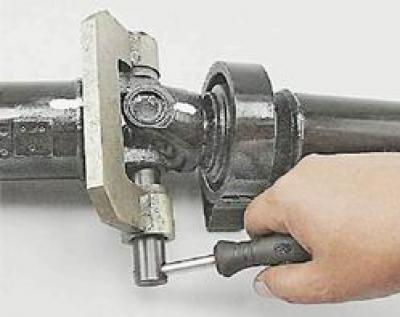

2. The bearings are installed in the forks of the joints with an interference fit. In case of corrosion, the tightness in the connection increases further, therefore, in order to avoid damage to the forks during disassembly, it is recommended to use not a hammer, but a special puller and pre-treat the entire hinge with penetrating grease.

3. With the help of a puller, we partially press the bearing into the puller cup until the crosspiece stops against the fork. In this case, the bearing comes out of the fork only 1/3 of its height.

4. We clamp the cardan shaft in a vice for the hinge fork so as not to deform the pipe. We strike with a hammer through a drift on the lugs of the fork of the front propeller shaft, shifting the crosspiece all the way into the fork. In this case, the bearing is partially pressed out.

5. We make two half rings from a pipe segment.

6. Move the fork of the front driveshaft with the cross in the opposite direction and install the half rings on the spike of the cross (one half ring shown).

7. Using a puller, press out the bearing.

8. We derive the cross from the fork of the rear driveshaft.

9. Similarly, we press the bearing out of the fork of the front driveshaft, holding it in a vise, but so as not to deform the pipe.

10. Remove the cross.

11. By striking with a hammer through a drift, we press out the bearings from the forks of the rear and front propeller shafts.

Assembling the universal joint

Before assembly, we additionally clean the hinge forks from dirt.

During the assembly process, it is necessary to ensure the axial clearance of the cross in the range of 0.01-0.04 mm. A larger gap makes the bearing seals leaky and unbalances the gear. The regulated clearance is ensured by the installation of retaining rings of the appropriate thickness. Retaining rings are available as spare parts in thicknesses from 1.50 to 1.62 mm.

Attention! The cross and the bearing set must be replaced at the same time.

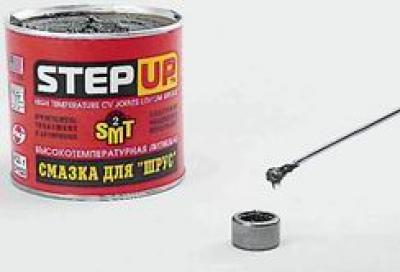

1. Before installing new bearings and crosses, making sure that these parts are clean, generously cover the needle rollers with grease. You can use Fiol-2U, No. 158, MC1000, SHRUS-4 or other grease with similar properties. We fill with grease and the holes of the spikes of the cross.

Attention! Do not use liquid oil, various greases, graphite grease, as well as CIATIM-201 for lubrication of cardan joints.

We cover the holes of the fork lugs with a thin layer of grease to facilitate pressing and protect against corrosion.

2. We put sealing rings on the spikes of the cross (bifurcated lip towards the bearing) and install plastic end washers in the holes of the spikes of the cross.

3. We place the cross between the lugs of the fork.

With light blows with a hammer through the spacer, we press the bearing into the fork a little deeper than the groove for the retaining ring. Using pliers, install the retaining ring into the groove.

4. Turning the fork over, we press in the second bearing until the first bearing rests against the retaining ring. Install the circlip on the second bearing.

5. Similarly, we press the bearings into the eyes of the second fork.

6. After pressing all the bearings and installing the circlips, tap the lugs of the forks with light blows of a hammer. This must be done in order to press the bearings against the circlips. In this case, gaps will appear between the ends of the spikes of the cross and the bottoms of the bearings, which are necessary for the normal operation of the connection.

Having assembled the hinge, you should check it for ease of swing and the absence of axial play that is noticeable by hand in both forks. If such a play is found, thicker retaining rings should be installed.

Removing the intermediate support

The intermediate support usually has to be removed when its bearing is worn, however, by this time, as a rule, the elastic cushion of the support is also damaged. Therefore, it is more expedient to replace the support with the bearing assembly.

You will need a universal two-jaw puller to get the job done.

1. We clamp the front driveshaft in a vice so as not to deform the pipe.

2. With a thin beard, unlock the nut of the front universal joint fork.

3. socket wrench by 27 mm unscrew the nut.

4. Using a two-jaw puller, we press the fork from the splines of the cardan shaft.

5. Remove the plug and mudguard.

6. Having installed an intermediate support on two suitable keys or rods, we knock out the shaft from the bearing through a soft metal drift.

7. Remove the second dirt deflector from the shaft.

Installing an intermediate support

1. Install the intermediate support in reverse order. We apply any grease to the splines of the front propeller shaft to protect against corrosion.

2. Tighten the new nut of the front propeller shaft yoke to a torque of 79.4-98.0 N·m and lock it with a beard.

Removing the flexible coupling

The flexible coupling usually has to be removed to replace its rubber element (when damaged). If the element is not damaged and will be installed in place, a worm-drive clamp with a diameter of at least 140 mm should be purchased to tighten the coupling during installation. The new coupling is supplied complete with a special mounting collar.

1. Remove the driveline (see "Cardan transmission - removal and installation").

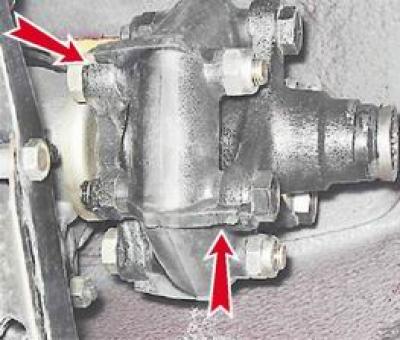

2. socket wrench by 13 mm with an extension, unscrew the two nuts securing the gearbox cross member to the body.

3. For easy removal and subsequent installation (in case of using the old clutch) we tighten its rubber element with a clamp.

4. socket wrench by 19 mm unscrew the three self-locking nuts of the coupling bolts, holding the bolts from turning with a wrench of the same size.

5. Remove the coupling together with the centering ring and rubber seal.

6. Having unscrewed the three nuts of the bolts of the elastic coupling to the flange of the front propeller shaft, we separate the parts.

Installation of flexible coupling

1. Install a new clutch in reverse order.

At the same time, be sure to ensure that the protrusions on the coupling enter the corresponding grooves of the flanges of the front propeller shaft and the output shaft of the gearbox.

2. Install the driveline on the car (see "Cardan transmission - removal and installation").