Execution sequence

1. We install the car on a viewing hole or overpass (see "Vehicle preparation for maintenance and repair").

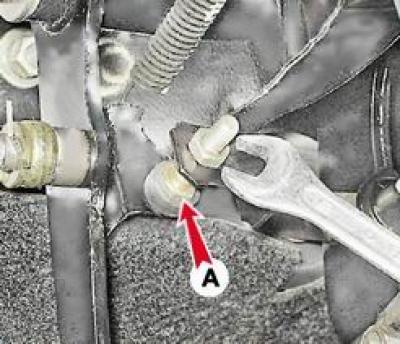

2. In the passenger compartment, we check the free travel of the clutch pedal, which should be within 0.4-2 mm from the upper position of the pedal until the pusher stops against the master cylinder piston. We make adjustments if necessary. For this key by 10 mm loosen the lock nut of the clutch pedal travel stop and, turning the stop A, set the required clearance.

3. We clean the pusher from dirt and apply penetrating lubricant to its threads.

4. We check the free play of the pusher of the working cylinder, on which the free play of the release bearing depends. To do this, manually press the clutch fork back until it stops, while the free play of the pusher should be within 4-5 mm. If the spring force is too large, then for convenience it can be disconnected from the lever.

5. To adjust the free play of the pusher with a key by 17 mm we hold the adjusting nut of the pusher from turning, and with the key by 13 mm loosen the locknut.

6. Holding the pusher by the flats from turning with a key by 8 mm, turn the key by 17 mm adjusting nut and set the required free play of the pusher (4-5 mm).

7. While holding the pusher adjusting nut, tighten the locknut.

8. In the cabin, we check the total free play of the clutch pedal, which should be within 25-35 mm from its upper position before the clutch is released. If necessary, repeat steps 2-7.