The car can be equipped with a five- or four-speed gearbox. Gearbox assemblies and most of their parts are interchangeable.

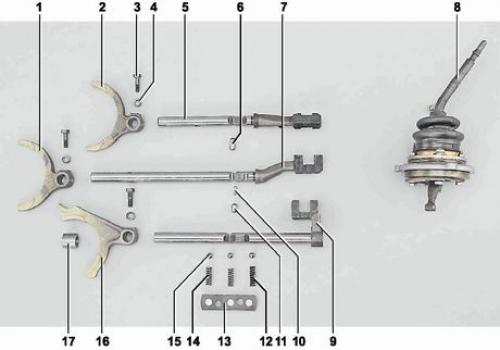

Gear shift drive parts: 1 - fork of inclusion of the III and IV gears (2101-1702024); 2 - fork of inclusion of the 1st and 2nd gears (2101-1702024); 3 - fork mounting bolt (2101-1702028); 4 - spring washer 6 (10516470); 5 - rod of the fork of inclusion of the 1st and 2nd gears (2107-1702060); 6 - cracker (2101-1702107); 7 - rod of the fork of inclusion of the III and IV gears (2107-1702071); 8 - shift lever with gear selection mechanism (2107-1703080); 9 - fork rod for engaging V-th gear and reverse gear (2107-1702080); 10 - cracker (2101-1702108); 11 - cracker (2101-1702109); 12 - spring of the retainer of the rod of the V-th gear and reverse gear (2108-1702087); 13 - rod retainer cover with gasket (2101-1702090); 14 - rod retainer springs (2101-1702087); 15 - ball clamps (2101-1702077); 16 - fork for engaging V-th gear and reverse gear (2107-1702028); 17 - remote bushing (2101-1702084-10)

The five-speed gearbox consists of a steel front cover (installed in the clutch housing) and cast aluminum alloy crankcase and rear cover. The connections of the gearbox housing with the rear cover and the clutch housing are sealed with gaskets. At the front, on seven studs of the gearbox, a clutch housing is installed, which is attached to the box with nuts and spring washers, and at the rear, the gearbox is mounted on two studs to the support of the power unit.

front cover box is pressed into the clutch housing. The input shaft oil seal is installed in the cavity of the cover. In the end wall of the cover there is a hole for draining oil flowing out of the box crankcase in case of damage or wear of the stuffing box.

In the box crankcase gears are installed: primary and secondary shafts with gears and synchronizers, an intermediate shaft and parts of the gear shift drive. In the left side wall of the crankcase, a filler hole is made, closed with a plug with a conical thread. From below, the crankcase is closed with a cover stamped from steel and fixed on ten studs with nuts. The lid has a drain hole closed with a plug with a conical thread and a permanent magnet. The crankcase cavity communicates with the atmosphere through a hole in the top of the crankcase front wall and a breather mounted on the clutch housing. A hole is made in the rear wall of the crankcase for the passage of oil into the cavity of the rear cover. The volume of oil poured into the gearbox is 1.6 liters.

Gear change drive - mechanical. It consists of a gear lever, a gear selector, three rods with forks, latches and a locking device. A handle is attached to the top of the lever on the thread. The lever shaft is connected to the lower part of the lever through elastic damper bushings, which absorb vibration and ensure smooth shifting. The lever housing assembly with the gear selection mechanism and the ball joint housing is fixed on top of the rear cover studs with three nuts. The spherical part of the lever is movably mounted in the body of the ball bearing. The lower part of the lever goes into the groove of one of the rods. The lever, turning in the ball joint, acts on the rod, moving it and the fork, which is fixed motionless on the rod. The 1st and 2nd gear engagement fork rod and the 3rd and 4th gear engagement fork rod are movably mounted in the openings of the front and rear walls of the crankcase. The fork rod for engaging the V-th gear and reverse gear is installed in a hole made in the tide of the rear wall of the crankcase. The rods are held in the neutral or on positions by ball spring-loaded detents, for which three sockets are made in each rod. Clamps with springs are located in bushings pressed into the crankcase holes and closed with a common cover. To prevent simultaneous engagement of several gears (rod movement) the drive has a locking device consisting of three biscuits located in the holes of the stem of the III and IV gears and the rear wall of the crankcase.

Back cover mounted on six studs and secured with nuts and spring washers. On the left side of the rear cover, a speedometer drive is fixed, the driven gear of which engages with the helical gear of the drive mounted on the splines of the rear neck of the output shaft.

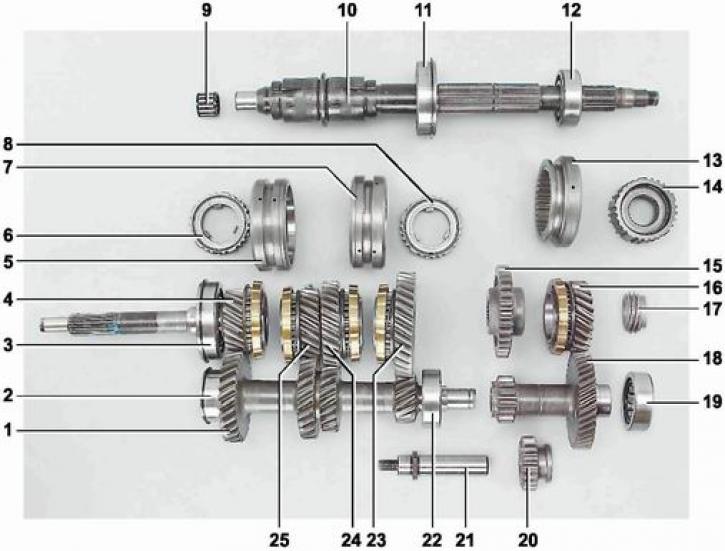

input shaft manufactured integrally with a helical gear of constant meshing. A straight-toothed rim of the fourth gear synchronizer is pressed onto the rear belt of the shaft, and then welded. On the crown of the IVth gear, a spring-loaded synchronizer blocking ring is installed, secured with a retaining ring. The teeth of the inner crown of the synchronization ring engage with the teeth of the 4th gear synchronizer. Splines are made on the front of the shaft, on which the clutch driven disk is located. The shaft rotates in two ball bearings; the front one is located at the end of the crankshaft, and the rear one is located in the front wall of the gearbox housing. A set ring in the groove of the rear bearing outer ring prevents axial movement of the shaft. The output shaft, which is on the same axis as the input shaft, rotates in three bearings. The front roller bearing is located in the bore of the end of the input shaft, the intermediate ball bearing is located in the rear wall of the crankcase. The rear roller bearing is installed in the seat of the rear cover and is sealed from the outside with an oil seal. At the rear splined end of the output shaft, a flange of the flexible coupling of the cardan shaft is attached. Gears with synchronizers are movably mounted on the secondary shaft. They are made in the form of a single block

Shafts and gears of a five-speed gearbox: 1 - intermediate shaft (2107-1701050); 2 - front intermediate shaft bearing (2101-1701068): 3 - input shaft rear bearing (2101-1701033); 4 - input shaft with IV gear (2105-1701020); 5 - synchronizer clutch of III and IV gears (2101-1701116); 6 - synchronizer clutch hub (2101-1701119); 7 - synchronizer clutch of the 1st and 2nd gears (2101-1701116); 8 - synchronizer clutch hub (2101-1701119); 9 - front roller bearing of the secondary shaft (2101-1701108-01); 10 - secondary shaft (2107-1701105-10); 11 - intermediate bearing of the secondary shaft (2101-1701190); 12 - rear bearing of the secondary shaft (20715580); 13 - V-th gear synchronizer clutch (2107-1701176); 14 - synchronizer clutch hub (2108-1701148); 15 - reverse gear (2107-1701140); 16 - gear with V-th gear synchronizer (2107-17011157); 17 - speedometer drive gear (2106-1702158); 18 - gear block V-th gear and reverse gear (2107-1701157); 19 - gear block bearing (2108-1701031-04); 20 - intermediate reverse gear (2121-1701080); 21 - an axis of an intermediate gear wheel of a backing (2107-1701092); 22 - rear intermediate shaft bearing (2107-1701073-02); 23 - gear with synchronizer of the 1st gear (2105-1701112); 24 - gear with synchronizer of the 2nd gear (2101-1701127); 25 - gear with synchronizer III gear (2101-1701131)

helical transmission gear and synchronizer ring gear, with locking rings attached to them. The gears of the gears are in constant mesh with the corresponding gears of the countershaft and the gear block of the Vth gear, and the reverse gear.

intermediate shaft made in the form of a block of four gears and rotates in bearings installed in the front and rear walls of the crankcase. The intermediate shaft drive gear is in constant engagement with the input shaft gear. To the rear end of the intermediate shaft, a gear block of the Vth gear and reverse gear is bolted. The other end of the block rests on a bearing in the wall of the rear cover of the gearbox housing.

On the splines of the secondary shaft a reverse gear is installed between the rear wall of the crankcase and the V-th gear. The connection of the reverse gears is carried out through an intermediate gear mounted on the axle, with the possibility of axial movement. The axle is fixed with a nut on the rear wall of the crankcase. The gear fork enters into the annular groove of the gear, when it is moved, the intermediate gear engages with the reverse gears.

Hubs of synchronization couplings are fixedly mounted on the secondary shaft. The protrusions on the inner surface of the hubs of the synchronization couplings of the 1st - 2nd and 3rd - 4th gears go into three grooves on the shaft, and the hub of the Vth gear coupling is put on the splined part of the shaft. A gear synchronization clutch is put on the outer ring gear of the hub with its inner ring gear, which forms an engagement with the clutch.

shift forks fit into the annular grooves on the outer side of the synchronization sleeves. When the stem is moved, the fork displaces the clutch. The clutch, acting on the synchronizer blocking ring, shifts it. Under the action of frictional forces arising between the clutch and the synchronization blocking ring, the speed of rotation of the gear and the hub is aligned. The teeth on the gear timing clutch engage with the teeth on the gear timing ring. The moment is transmitted from the gear through the clutch and hub to the output shaft.

Four speed gearbox differs in the shape of the back cover. The gearbox does not have a driven gear with a synchronizer and a V-speed synchronization clutch. The reverse drive gear is secured to the intermediate shaft shank with a circlip.