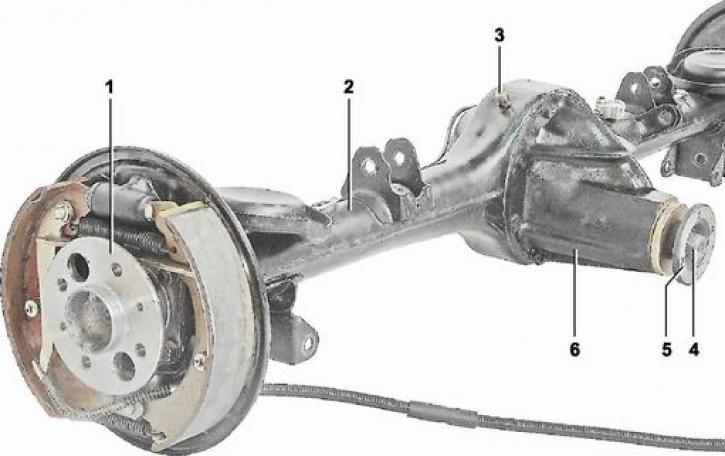

Rear axle: 1 - half shaft (2103-2403069); 2 - rear axle beam (2101-2401010-01); 3 - breather (2101-2401050-01); 4 - nut of the shank of the final drive pinion M16x1.5 (12574921); 5 - drive gear flange with a dirt deflector (2101-2201100-10); 6 - gearbox housing (2101-2402015-10)

On welded sheet steel rear axle beam bolted cast iron gearbox housing, which houses the main gear and differential.

main gear - hypoid, the axis of the drive gear is shifted down, the gear ratio is 3.9, 4.1 or 4.3 (depending on vehicle modification). The gear ratio is marked on the driven gear.

Differential - gear, conical, two-satellite. The differential housing, together with the final drive driven gear attached to it, is installed in the crankcase on two tapered roller bearings. The adjustment of the bearings and the axial position of the gear is carried out by two adjusting ring nuts with an external thread, wrapped in split bearing beds.

drive gear, made integral with the shank, mounted in the crankcase also on two tapered roller bearings. Its axial position is determined by the thickness of the adjusting ring placed between the gear and the inner bearing. A flange is installed on the splined end of the shank, bolted to the flange yoke of the rear cardan joint.

Flange fastened to the shank with a nut, which simultaneously adjusts the shank bearings. A spacer sleeve is installed between the inner rings of the bearings, which deforms when the nut is tightened, providing a preload in the bearings.

half shafts their splined ends enter the holes of the side gears of the differential. The outer ends of the axle shafts are supported by ball bearings installed in the bores of the flanges of the rear axle beam. The axle shafts are secured against axial displacement relative to the bearings by pressed locking rings. At the ends of the axle shafts there are flanges to which the rear wheels of the car are bolted.

Reducer the rear axle is lubricated with gear oil poured into the axle beam in a volume of 1.3 liters. To change the oil in the beam, filler and drain holes are made, closed with plugs with a self-sealing conical thread.

The axle bearings are fitted with rubber-coated sealing washers and filled with lifetime grease. The leakage of oil from the rear axle is prevented by oil seals installed at the ends of the axle shafts and the shank of the drive gear.

To prevent the air pressure inside the bridge from increasing during the working heating of the gearbox, which can lead to oil leakage through the seals, a breather is installed on the beam (safety valve).