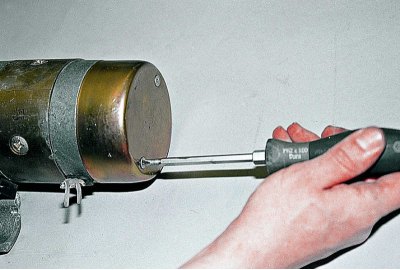

key «at 13» loosen the nut securing the wire to the traction relay...

...and disconnect the wire end.

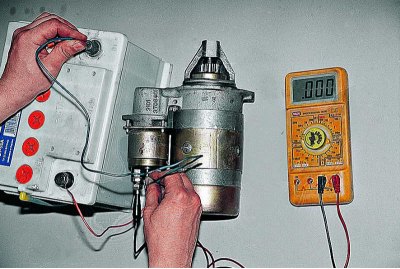

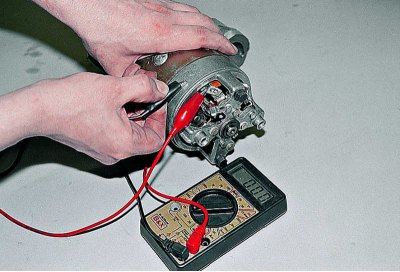

We apply a voltage of 12 V to the output of the relay,...

... «minus» - on the body, and connect the ohmmeter to the contact bolts. In this case, for a working relay, the armature should push the overrunning clutch into the window of the front cover, and the contact bolts should close. We replace the faulty traction relay with a new one.

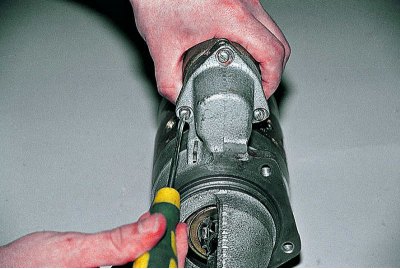

Use a Phillips screwdriver to remove the three screws...

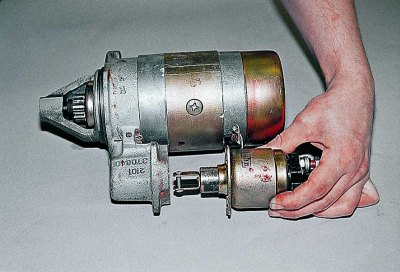

... and remove the traction relay.

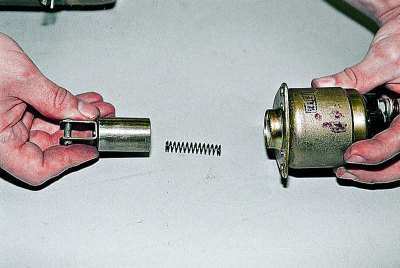

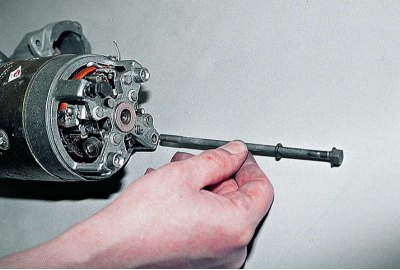

We take out the stem with the spring from the relay housing.

We install a new traction relay in the reverse order.

To further disassemble the starter, use a Phillips screwdriver to unscrew the two screws...

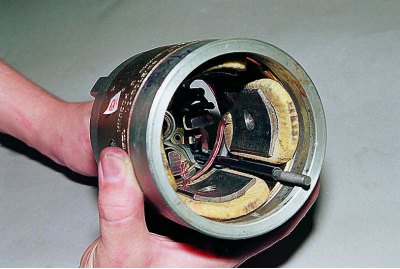

...and remove the lid.

To check the condition of the brushes with a slotted screwdriver, unscrew the screw securing the contact wire...

... and, having pressed the spring with a screwdriver, we remove the brush. In the same way, we remove the three remaining brushes. Replace brushes worn to a height of 12 mm or less.

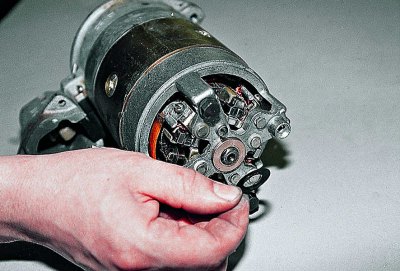

By connecting an ohmmeter in turn to the terminals of the stator windings, we check them for a short to the case and for an interturn short. At the same time, we make sure that the free winding leads are isolated from the housing.

Using a screwdriver, remove the retaining ring.

We remove the washer from the axle.

key «on 10» loosen the two bolts...

...and take them out.

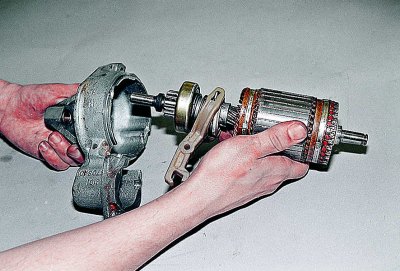

We disconnect the starter housing and remove the insulating tubes of the coupling bolts from it.

External inspection check the condition of the collector and windings. Charring of windings is not allowed. With a slight burn of the collector, we clean its plates with a fine abrasive sandpaper. In case of severe burning and wear, it is better to replace the anchor. Seizures and enveloping of bronze from bearings on the necks of the armature shaft are eliminated with the finest sandpaper, followed by polishing.

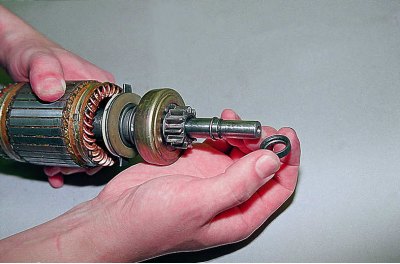

We check the armature windings for a short circuit with an ohmmeter. We replace the defective anchor.

Remove the rubber seal from the drive cover.

Remove the adjusting washer from the armature axis. When assembling, it must be installed in place.

Unpin the lever axle.

We knock out the axle with a beard...

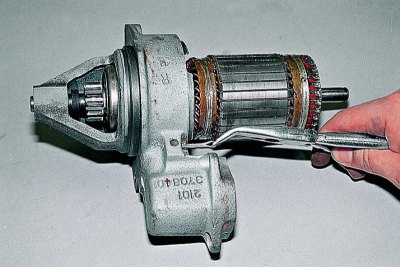

... and take out the anchor with the drive.

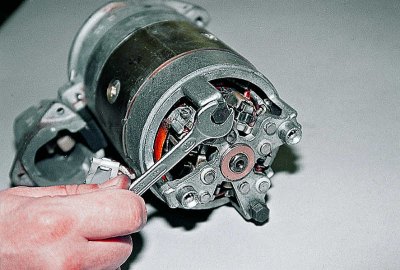

Using a screwdriver, remove the overrunning clutch drive lever.

The gear should rotate easily in one direction and not rotate in the other, not have chips and nicks on the lead-in part of the teeth. If the gear is worn or the clutch is defective, we change the assembly.

Leaning the axis of the anchor on a wooden block, through the key «at 13» knock the limiter off the retaining ring.

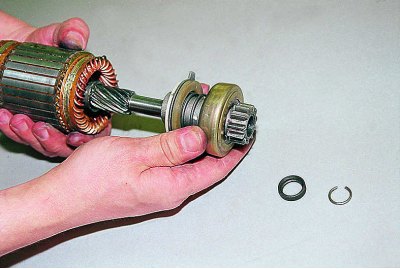

Using a screwdriver, remove the retaining ring.

We remove the limiter and the overrunning clutch assembly with the drive gear from the axle.

Having changed the clutch assembly, put the retaining ring in place and put on the limiter with a conical groove to the armature winding.

The limiter is pressed onto the retaining ring with hammer blows through the key «at 13».

We remove coal dust from the body and brush holder with compressed air. We lubricate the driving ring and the plastic surfaces in contact with it with Litol-24 or grease No. 158. Support bearings - rotor bushings, screw splines of the armature shaft and the freewheel hub are lubricated with engine oil.

Further assembly is carried out in the reverse order of disassembly.

Before assembling the starter, insert the housing tie bolts into the appropriate holes.

Attention! If only one bolt was insulated, when assembling the starter, we put the insulating tube on the one that can touch the copper bus connecting the starter stator windings.

To snap the retaining ring, we press the starter armature through the cover sleeve on the drive side.