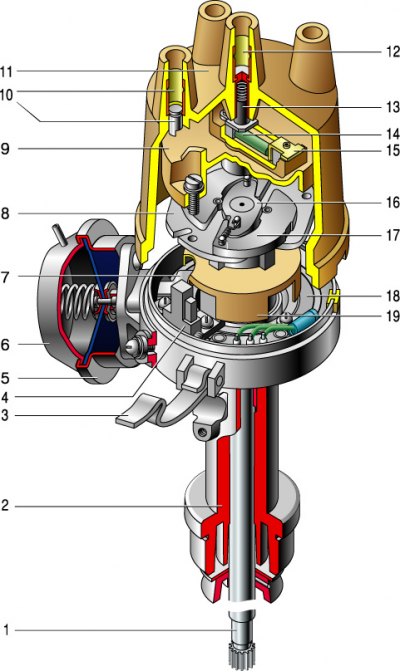

1 - roller; 2 – the case of the gauge-distributor of ignition; 3 - locking spring cover; 4 – contactless sensor; 5 - housing of the vacuum regulator; 6 - diaphragm; 7 – draft of the vacuum regulator; 8 - base plate of the centrifugal regulator; 9 – ignition distributor rotor; 10 – side electrode with terminal; 11 - cover; 12 – central electrode with terminal; 13 - coal of the central electrode; 14 - resistor; 15 - outer contact of the rotor; 16 - leading plate of the centrifugal regulator; 17 - weight of the centrifugal ignition timing regulator; 18 – contactless sensor support plate; 19 - screen.

Four-spark ignition distributor, with a non-contact sensor of control pulses and built-in vacuum and centrifugal ignition timing controllers.

The ignition distribution sensor transmits control signals to the switch, setting the moment of sparking, and distributes high voltage current pulses to the spark plugs.

The sensor is installed in the front of the cylinder block on the left side.

The body of the sensor-distributor is cast from aluminum alloy. Two plain bearings are pressed into the housing shank, in which the roller rotates. The screen is fixed on the roller. When the roller rotates, the teeth of the screen pass through the slot of the proximity sensor, creating control pulses in the electrical circuit of the sensor. A centrifugal regulator is mounted in the upper part of the roller, on the base plate of which the rotor is fixed (slider). When the roller rotates, the weights of the centrifugal regulator diverge under the action of centrifugal forces, turning the screen at a certain angle in the direction of rotation of the roller. Control pulses are generated in advance, which is greater, the faster the rotation. The angle of rotation is limited by the size of the groove in the base plate of the centrifugal governor.

The base plate of the proximity sensor is mounted on a ball bearing, which allows it to rotate around the axis of the roller. The plate is connected by a rod to the diaphragm of the vacuum ignition timing controller. Underpressure (supplied through a hose from the throttle space of the carburetor) acts on the diaphragm of the vacuum regulator, and the rod rotates the base plate together with the sensor relative to the screen, thereby ensuring the optimal ignition timing depending on the engine load.

From above, the housing of the sensor-distributor is closed with a cover with slots for high voltage wires. On the inside of the lid, a spring-loaded coal is mounted in its central electrode. Rotor with contact plate (slider) distributes the high voltage current to the spark plugs according to the firing order of the cylinders (1–3–4–2). The ignition distributor shaft rotates clockwise when viewed from above.

Distributor 30.3706 and sensor-distributor 38.3706 are the same in terms of seats and mounting method on the engine, and their covers and rotors (runners) interchangeable.

Switch 3620.3734

The switch converts the control pulses of the proximity sensor into a pulsed current supplied to the primary winding of the ignition coil. The health of the switch cannot be checked without special equipment.

Attention! To avoid damage to the switch, do not disconnect its connector when the ignition is on; do not remove the battery terminals while the engine is running. Systematically check the security of fastening «masses» switch to the body.

Otherwise, the non-contact system is similar to the contact ignition system.