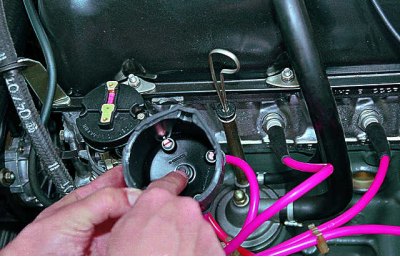

We take out the central high-voltage wire (connected to the ignition coil) from the distributor cap.

We bring its tip at a distance of about 1 millimeter to the bare contact «masses» (e.g. to a bolt or stud on an engine).

While holding the wire in this position, we ask the assistant to turn the engine crankshaft with the starter.

If there is no spark at the same time, we check in order: the gap between the contacts of the breaker (see Adjustment of the angle of the closed state of the breaker contacts).

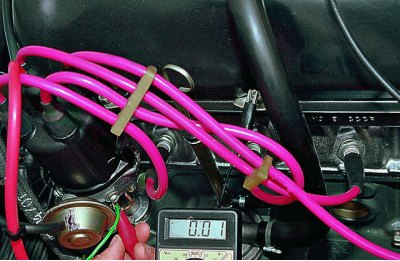

The presence of voltage at the low-voltage contact of the distributor when the ignition is turned on can be checked with a tester or a test lamp.

Tester (voltmeter) when cranking the crankshaft, it should show the periodic occurrence of voltage, and the control lamp should light up and go out (see Checking the ignition timing).

Replace the ignition coil with a known good one.

If there is a spark, install the center wire in place and repeat the experiment with any of the spark plug wires.

If between the spark plug wire and «weight» there is no spark, perhaps: condensation on the inner wall of the distributor cap; damage to the carbon of the central electrode; runner resistor failure...

... as well as oxidation of the electrodes of the distributor cap and runner.

If there is a spark on the candle wire, we check the condition of the candles, the moment the ignition is installed (see relevant sections).