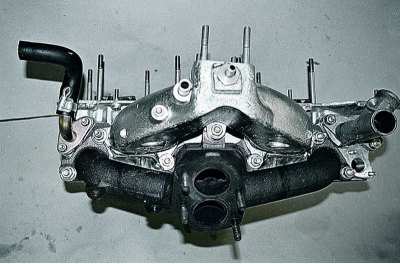

We unscrew the seven nuts securing the manifolds to the block head and remove them (see Replacing the intake and exhaust manifold gaskets).

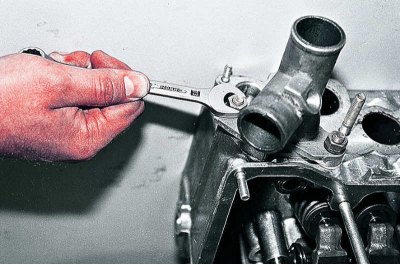

key «on 10» unscrew the two nuts securing the pipe...

...and remove the tube.

key «at 13» unscrew the two nuts securing the double pipe...

... and remove it from the head of the block. Gaskets are installed between the nozzles and the head.

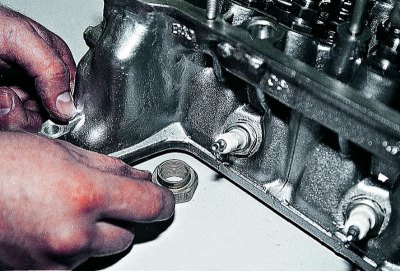

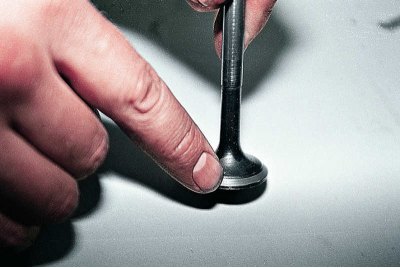

We put an impromptu stop under the valve (a nut, but a wooden block is better).

Dry the valve (see Replacing the valve stem seals of the gas distribution mechanism).

Remove the valve from the guide bushing.

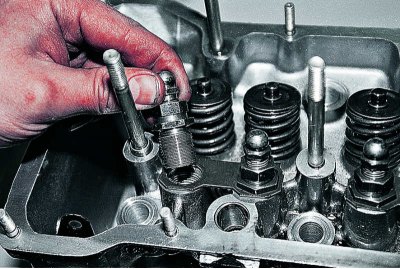

Apply lapping paste to the valve plate.

Install the valve in place. We put a lapping tool on the valve stem.

Pressing the valve plate to the seat, turn it alternately in one direction or the other.

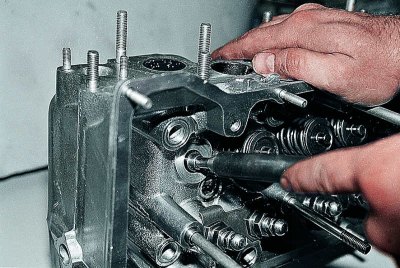

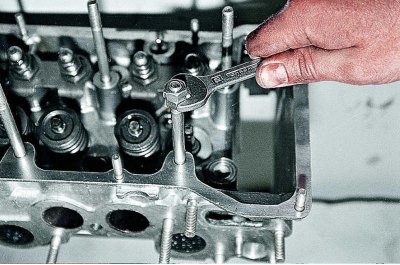

If necessary, for convenient access to the outer valves with a key «at 13» unscrew the two extreme studs, after locking the two nuts on them...

We continue grinding the valve until an even matte rim appears on the seat and the chamfer of the valve disc.

Thoroughly flushing, install the valve in place, replacing the oil seal (see Replacing the valve stem seals of the gas distribution mechanism).

head «at 12» unscrew the plug...

...and remove it together with the adjusting bolt and locknut. We replace them if necessary.

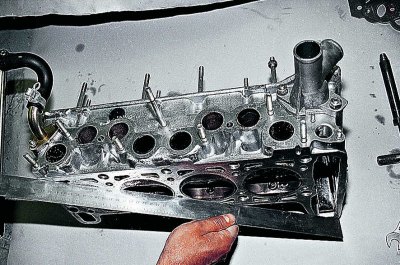

With a metal ruler, we check the mating plane of the cylinder head. Permissible clearance - 0.15 mm.