Using a Phillips screwdriver, loosen the clamps of the inlet and outlet fuel hoses.

Remove the hoses from the pump fittings. To prevent gasoline from leaking, we plug the hoses with M8 bolts.

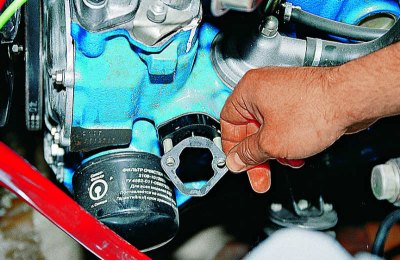

key «at 13» unscrew the two nuts securing the pump...

...and remove it from the studs.

We remove the outer adjusting gasket from the studs,...

... a heat-insulating spacer with a pusher...

...and the second gasket, which we mark so that we do not confuse it with the first during assembly.

Install the new pump in the reverse order of removal. At the same time, we install the gaskets each in its place.

For reliable operation of the fuel pump, we periodically check and, if necessary, select the thickness of the outer adjusting shim. To do this, turn the crankshaft of the engine so that the pusher protrudes by a minimum amount.

After installing the heat-insulating spacer with both gaskets, the pusher of the fuel pump drive should protrude by 0.8–1.3 mm.

A gasket 0.27–0.33 mm thick must be installed between the cylinder block and the heat-insulating spacer. Outdoor laying (between spacer and pump) is selected for the required protrusion of the pusher. This gasket can be made independently by cutting it from a paronite sheet of suitable thickness.