Attention! The gearbox consists of a large number of parts, many of them are similar, therefore, to facilitate assembly, the parts should be laid out on sheets of paper in order and be sure to sign each one.

Drain the gearbox oil (see Checking the level and changing the oil in the gearbox).

Removing the gearbox (see Gearbox replacement).

Remove the clutch release fork and the clutch release bearing (see Replacing the pressure plate assembly and clutch release bearing).

Thoroughly clean the dirt, wash the gearbox housing with a brush and hot water and detergent from the outside and put it on the workbench with the clutch housing down.

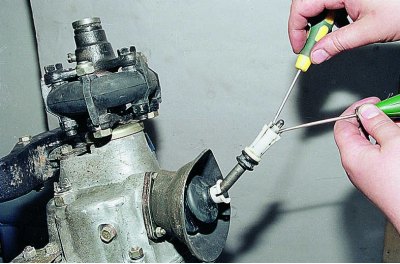

With two screwdrivers, we separate the sectors of the spacer sleeve and...

... remove it and the damper rubber bushing.

Remove the flexible coupling and flange from the output shaft of the gearbox (see Replacement of a cuff of a secondary shaft).

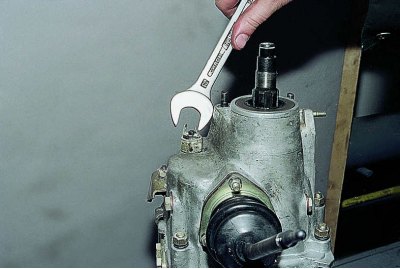

head «at 13» unscrew the two nuts securing the support...

...and take it off.

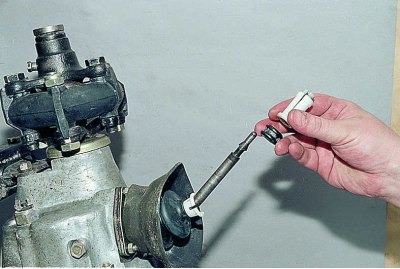

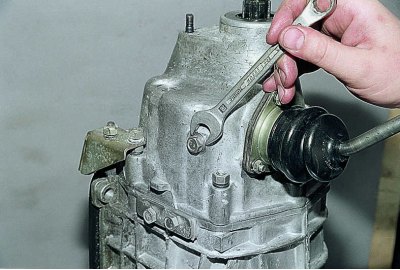

head «on 10» unscrew the nut securing the speedometer drive...

...and remove the speedometer drive.

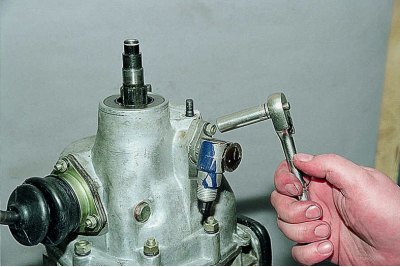

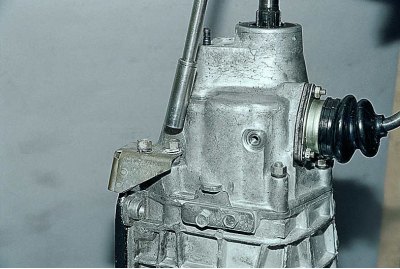

key «at 22» turn off the reverse light switch...

...and take it off.

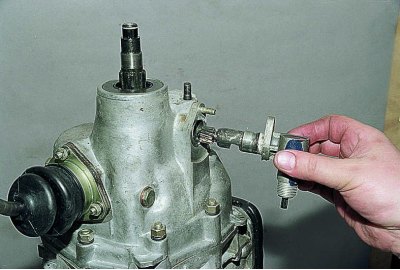

key «at 13» unscrew the stop for moving the gear lever.

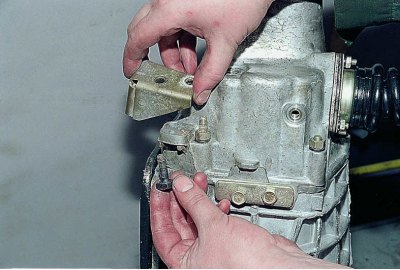

head «at 13» unscrew the two nuts securing the bracket.

Remove the bracket and remove the square head bolt.

head «at 13» unscrew the remaining nuts securing the rear cover of the gearbox.

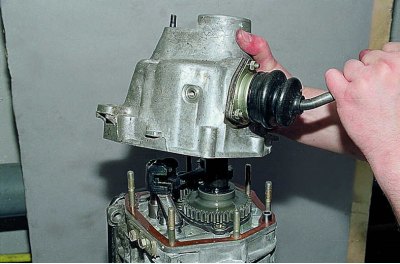

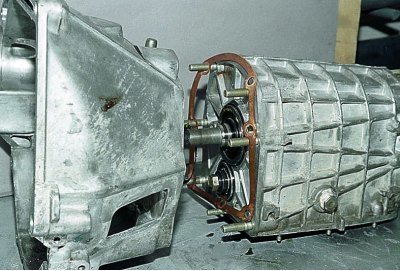

Remove the rear cover by moving the shift lever to the right to free it from the gear shift rods.

Carefully, trying not to damage, remove the rear cover gasket.

Remove the rear bearing.

Remove the speedometer drive gear and its retainer - a steel ball.

head «on 10» unscrew the bolt securing the reverse gear fork.

Remove the reverse gear and reverse gear.

Remove the spacer from the reverse gear.

With a puller, remove the retaining ring from the intermediate shaft.

Remove the reverse drive gear and spring washer.

With a puller, remove the retaining ring from the secondary shaft.

Remove the reverse driven gear and spring washer.

With an impact screwdriver, unscrew the four screws securing the bearing lock plate and the shaft of the reverse idler gear.

Remove the stop plate.

Remove the reverse intermediate gear shaft.

head «on 10» unscrew the ten nuts securing the bottom cover.

We remove the cover.

I put the gearbox on its side.

head «at 13» loosen one nut...

...and the head «at 17» - six nuts securing the clutch housing to the gearbox.

We disconnect the crankcases and remove the gasket.

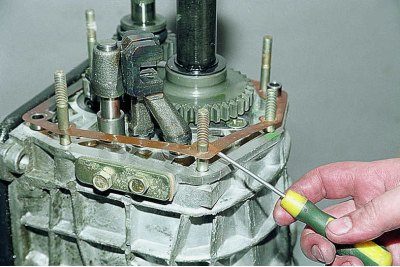

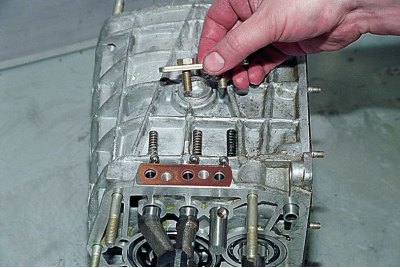

head «at 13» unscrew the two bolts securing the cover of the rod clamps.

We remove the cover and remove three springs and three balls from the holes.

We take out the stem of the fork of the reverse gear.

head «on 10» unscrew the bolt securing the fork of inclusion of I and II gears.

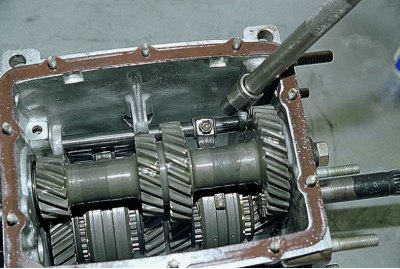

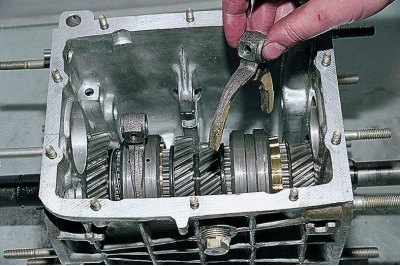

We take out the rods, at the same time removing the blocking crackers.

We take out the stem of the fork of inclusion of I and II gears.

head «on 10» unscrew the bolt securing the fork of inclusion of III and IV gears.

We take out the stem of the fork of inclusion of III and IV gears.

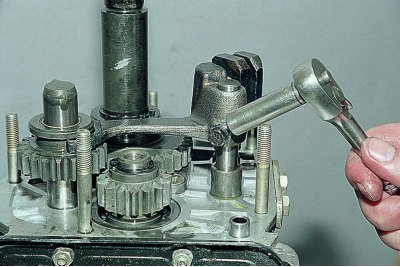

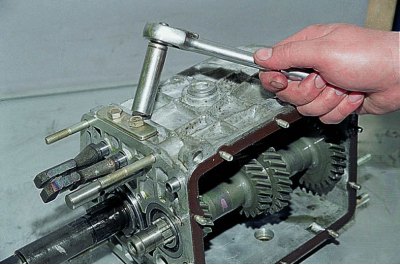

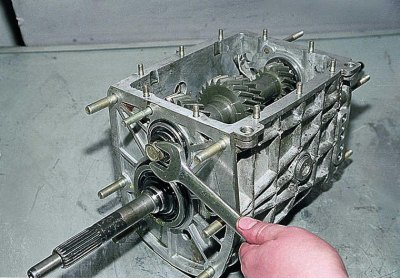

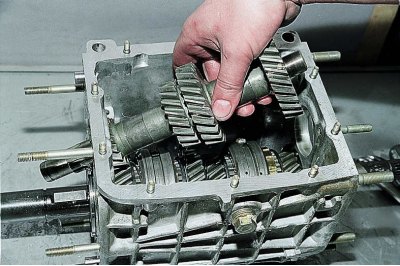

By pressing the clutches, we turn on two gears at once and with the key «at 19» unscrew the bolt securing the front bearing of the intermediate shaft.

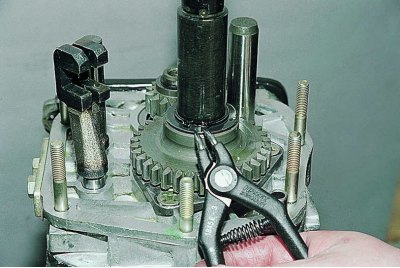

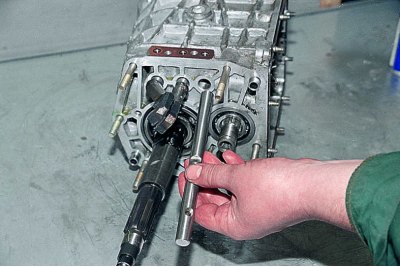

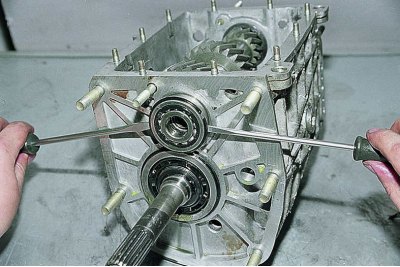

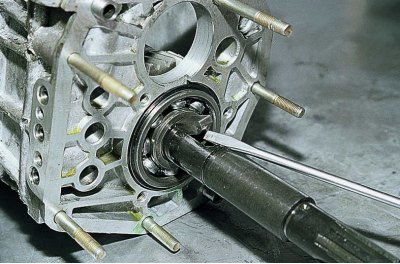

Prying with two screwdrivers for the retaining ring, we take out the front bearing of the intermediate shaft.

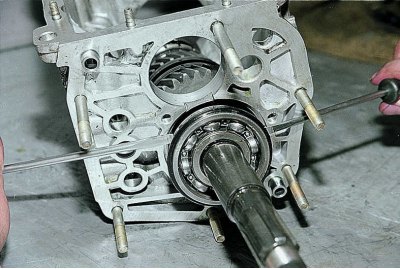

We push out the rear bearing of the intermediate shaft.

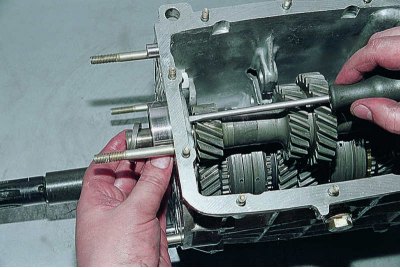

Having tilted, we take out the intermediate shaft from the gearbox housing.

We take out two shift forks.

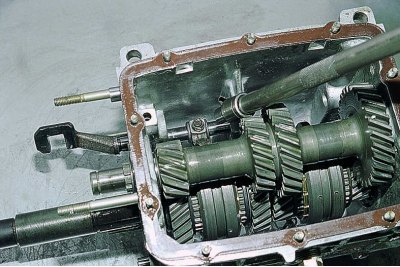

Prying with a screwdriver, we take out the input shaft assembly with the bearing and the synchronizer ring.

Remove the needle bearing from the output shaft.

Using a screwdriver, remove the key from the back of the output shaft.

Prying with two screwdrivers, remove the rear bearing of the secondary shaft.

We take out the secondary shaft from the gearbox housing.

Vertically install the secondary shaft, holding it in a vice through cardboard gaskets.

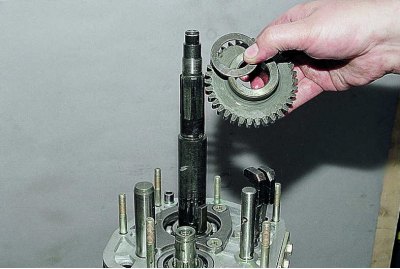

We remove the synchronizer clutch of III and IV gears.

Remove the retaining ring with a puller...

... and remove the synchronizer hub and spring washer.

Prying off with a screwdriver, remove the retaining ring, as well as the blocking ring and the synchronizer spring.

Remove 3rd gear gear.

Leaning the gear of the 1st gear on a rigid base, with a hammer, through a soft metal spacer, we knock out the secondary shaft...

... and remove the 2nd gear gear assembly, the 1st and 2nd gear synchronizer clutch, the synchronizer hub, the 1st gear gear assembly and the 1st gear gear bushing from it.

Synchronizer elements I, II and IV (on the main shaft) gears are disassembled similarly to the third gear synchronizer.

To remove the input shaft bearing...

... release the retaining ring with a puller...

... and remove it along with the spring washer.

Having rested the bearing on a rigid base, we knock out the input shaft with a hammer through a soft metal drift.

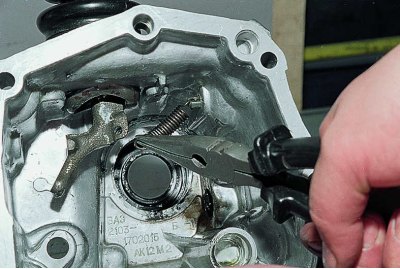

To remove the shift lever from the rear cover of the gearbox housing...

... disconnect the return spring from the lever.

key «on 10» unscrew the three nuts securing the ball joint of the lever and...

... remove the lever from the studs.

To replace the leader's cuff (primary) shaft, we knock out the cuff with a drift through the hole in the front cover of the gearbox and...

...remove it.

Thoroughly wash all parts in kerosene or diesel fuel and inspect them. The teeth of gears and couplings should not be chipped, scuffed, fatigue chipping and noticeable wear. The surfaces of the shafts, axles and gearshift rods must be perfectly smooth, free of burrs, burrs and heavy wear. There should be no cracks and nicks on the crankcase, and wear and traces of turning in the bores for bearings. Corrosion and traces of crushing and seizing are unacceptable on the splines of the shafts. Minor damage can be repaired with fine sandpaper followed by polishing, but it is better to replace the damaged parts with new ones.

All rolling bearings, both ball and roller bearings, must be in perfect condition, their radial play must not exceed 0.05 mm, any defects on the tracks and rolling elements are unacceptable. Separators should not have breaks, touching rings and melting (plastic). In general, if «mileage» the box exceeds 120 thousand km and the unit is being repaired with disassembly, it is better to replace all bearings with new ones, regardless of their condition, especially if severe damage to the gears and gear clutches has been noticed. We replace the cuffs with new ones in any case. When assembling, we lubricate all parts of the box, incl. we cover the bearing nests and the bearings themselves with gear oil, the joints of the crankcase and covers are covered with a thin layer of oil-resistant sealant, and the parts of the switching mechanism are covered with SHRUS-4 grease.

We assemble the gearbox in the reverse order of disassembly. The spring of the reverse fork rod detent differs from others in rigidity and has a black coating. Before installation, we cover the working surface of the cuffs with a thin layer of Litol-24 lubricant. We tighten the clamping washer bolt of the intermediate shaft bearing with a torque of 8.1–10.0 kgf·m. We tighten the nut of the rear end of the secondary shaft with a torque of 6.8–8.4 kgf·m.