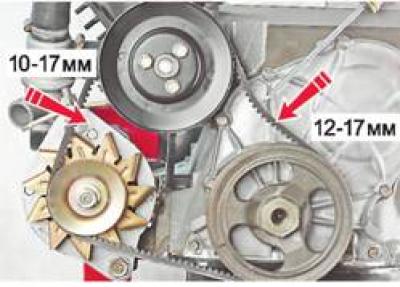

The belt tension is characterized by the amount of deflection in the section between the pulleys of the coolant pump and the crankshaft or the pulleys of the pump and the generator when a force of 10 kgf is applied in the middle of the section. In the first case, the deflection should be 12-17 mm, and in the second - 10-15 mm.

Visually assess the condition of the belt. In the presence of delaminations, tears and other mechanical damage, we replace the belt (see below).

1. We prepare the car for operations (see "Vehicle preparation for maintenance and repair").

2. To check the belt tension with a large screwdriver or other suitable object, press the belt branch in one of two places (shown by arrows) and check deflection.

3. If the deflection does not correspond to the specified values, then loosen the nut securing the generator to the adjusting bar (see below, "Generator - removal and installation").

4. With a mounting blade, we press the generator from the cylinder block, increasing the belt tension. If this requires excessive force, then by removing the engine mudguard (see "Mudguard - removal and installation"), wrench 19 mm (13 mm for alternator 9412.3701) loosen the nut securing the alternator to the engine bracket (see below, "Generator - removal and installation"). While holding the generator, tighten the nut securing the generator to the adjusting bar. We check the deflection of the belt, if necessary, increase or decrease its tension.

Attention! Excessive belt tension causes increased loads on the bearings of the coolant pump and alternator, which will lead to premature failure.

5. To replace the belt, loosen the nut securing the generator to the adjusting bar and with a mounting blade move the generator to the cylinder block until it stops (see above).

6. On injection engine Remove the crankshaft position sensor to remove the belt (see "Crankshaft Position Sensor - Check and Replace").

7. Remove the belt from the pulleys and install a new one.

8. Pull the belt (see above) and tighten the alternator mounting nuts.

9. Installation of the remaining removed parts is carried out in reverse order.