Air filter

The car is equipped with an air filter with a thermostat 4 (pic. 31), allowing you to automatically maintain a constant air temperature at the inlet to the carburetor.

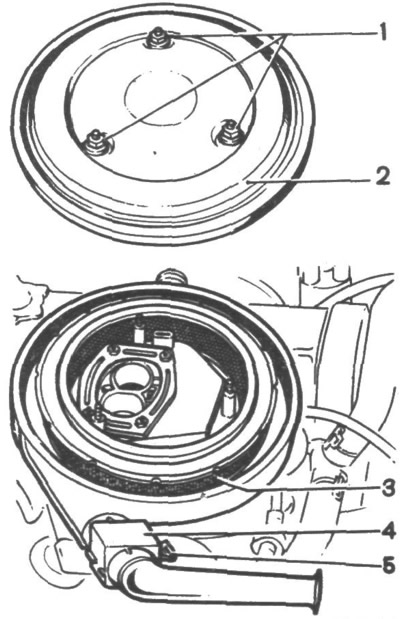

Pic. 31. Air filter:

1 - nut; 2 - cover; 3 - filter element; 4 - thermostat; 5 - handle.

Every 10,000 km run, check the operation of the thermostat. This operation is recommended to be carried out at a service station.

Every 20,000 km mileage, and in case of constant operation of the car on roads with increased dust content after 10,000 km, replace filter element 3, for which unscrew nuts 1 and remove cover 2.

Some of the cars produced can be equipped with an air filter with manual adjustment of the damper position in the thermostat housing. In this case, if the average temperature of the season is below plus 15°C, turn the knob 5 of the damper to the position «NOT», and at temperatures above plus 15°C - to the position «COLD».

Carburetor

Every 10,000 km run, wash with gasoline and blow compressed air through the carburetor fuel filter, as well as the fuel pump filter.

Every 20,000 km run, clean the carburetor inside, rinse with gasoline or benzene and blow with compressed air.

When cleaning the calibrated holes of the jets, do not use wire, so as not to disturb the size and cleanliness of the surfaces of these holes. When screwing in and out jets, be careful not to damage the threads in the holes.

Check and, if necessary, adjust the fuel level setting in the float chamber and the float stroke, for which:

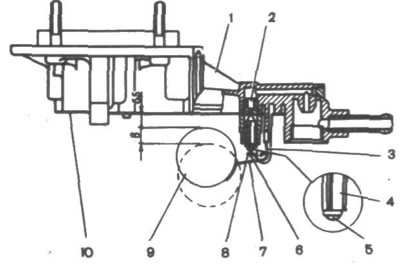

- make sure that the weight of the float is 9 (pic. 32) assembled with lever 7 is 12±1 g, that the float has no holes or dents and rotates freely on the axis;

- check whether the seat 2 of the needle valve 4 is securely tightened and whether the ball 5 of the damping device built into the needle valve 4 is hanging;

- install cover 1 vertically so that the fuel supply fitting is directed upwards, the needle valve is closed, and the float tongue 8 slightly touches the needle valve ball;

- check the distance between the float and the surface of the gasket 10 adjacent to the cover, which should be equal to 6.5 mm;

- change, if necessary, the position of the tongue to obtain the required size; the tongue must be perpendicular to the axis of the valve, and the contact surface of the tongue must not have damage that could cause the valve to hang;

- check the stroke of the float, which should be equal to 8 mm, changing the position of the stop 3 if necessary;

- check if the yoke 6 of the needle valve is preventing its free movement;

- reinstall the carburetor cap, making sure that the float can move freely without hitting the walls of the chamber.

Pic. 32. Setting the fuel level in the carburetor float chamber:

1 - carburetor cover; 2 - needle valve seat; 3 - emphasis; 4 - needle valve; 5 - ball; 6 - draw fork; 7 - lever; 8 - tongue; 9 - float; 10 - gasket.

Note. When changing the needle valve, also replace the seal between seat and bonnet.

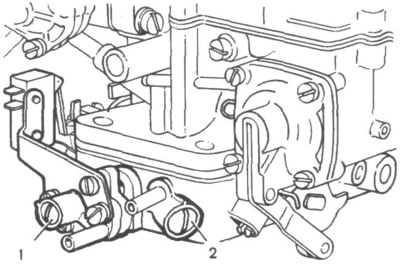

Every 10,000 km run, and on a new car after running the first 2000-3000 km, adjust the minimum speed of the crankshaft in idle mode. This adjustment should only be carried out at a service station. Independently it is allowed to carry out only re-adjustment of the idling system within the limits determined by the restrictive bushings 1 (pic. 33) and 2 on the screws for the quantity and quality of the mixture. Attempts to rotate the bushings at a greater angle will lead to their destruction. In this case, for the increased content of carbon monoxide in the exhaust gases (SO) and excessive fuel consumption, the plant is not responsible.

Pic. 33. Screws for adjusting the carburetor idle system:

1 - restrictive bushing of the mixture quantity screw; 2 - restrictive sleeve of the mixture quality screw.

Adjustment is carried out on a warm engine with adjusted gaps in the gas distribution mechanism and the correct setting of the ignition timing as follows:

- unscrew the restrictive sleeve 2 screws of the quality of the mixture to the stop;

- with a restrictive sleeve 1 of the mixture amount screw, set the crankshaft rotational speed within 850-900 min using the tachometer-1.

Check the adjustment of the idle system, for which, sharply press the accelerator pedal and release it - the engine should increase the crankshaft speed without interruption, and when it decreases to the minimum idle speed, it should not stop. If the engine stops, increase the engine speed with the limiter sleeve 1 of the mixture amount screw within the limiter.