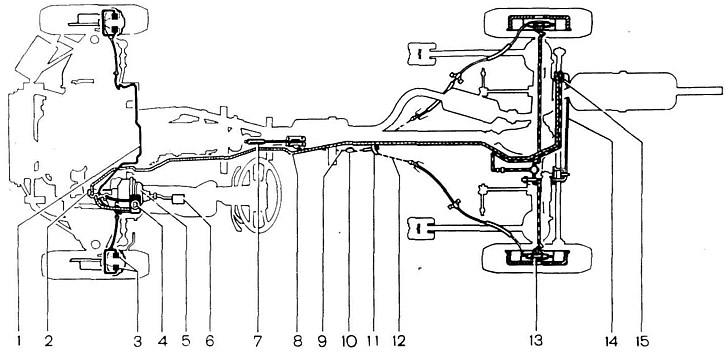

Pic. 54. Scheme of the brake system:

1 - front brake circuit; 2 - the main cylinder of the hydraulic brake system; 3 - brake cylinders of the front disc brake; 4 - a reservoir of a hydraulic drive of brakes; 5 - vacuum amplifier; 6 - brake pedal; 7 - parking brake lever; 8 - rear brake circuit; 9 - front parking brake cable, 10 - front cable guide roller; 11 - rear cable equalizer; 12 - rear night brake cable; 13 - wheel cylinder rear drum brake; 14 - torsion lever of the pressure regulator; 15 - pressure regulator.

Before servicing the brake system, clean each brake of dirt, rinse with warm water and dry with compressed air. It is not allowed to use gasoline, diesel fuel, trichlorethylene or other types of solvents, as they corrode the cuffs and seals of the hydraulic cylinders.

The surfaces of the friction linings of the brake pads must be clean, free of dirt and grease. Clean dirty pads with a wire brush and rinse with white spirit. If you find grease on the pads, check for grease or brake fluid leaks through the seals and repair. During maintenance, keep the brakes free of oil.

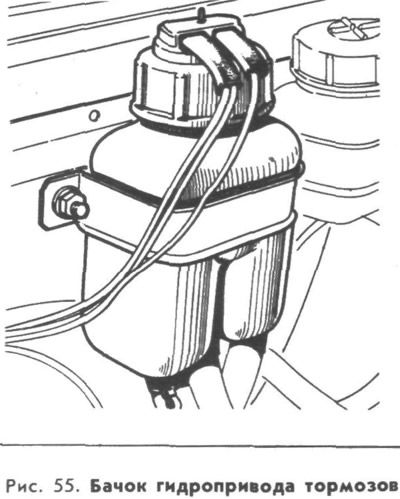

Hydraulic brake reservoir

Every 10,000 km mileage check the fluid level in the tank (pic. 55), which, when the cap is installed, must reach the lower edge of the filler neck. Add brake fluid «Dew» or «Tom». By pressing the pusher on the tank cover, check the correct operation of the liquid level indicator - with the ignition on, the control lamp should be lit with a constant light.

After 5 years of operation, it is recommended to replace the brake fluid with fresh one.

Flexible brake lines

Every 10,000 km, starting from 30,000 km, check the condition of the brake hoses. If small cracks are found on the outer sheath or blisters appear when pressing the brake pedal, replace the hose with a new one.

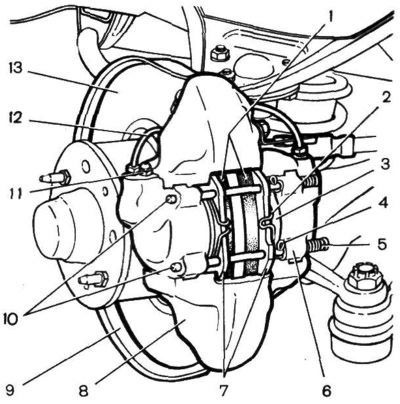

Front disc brakes

Every 10,000 km run, check the condition of the brake pads. Replace the pads if the thickness of the friction linings is 1 (pic. 56) will decrease to 1.5 mm. If you remove the pads not for replacement, then mark them so that you can put them in their places during assembly. To remove brake pads 7, remove cotter pins 4 and pins 10 with springs 2 and 5.

Pic. 56. Front disc brake:

1 - brake pads; 2 - spring; 3 - brake cylinder piston; 4 - cotter pin; 5 - spring; 6 - brake cylinder; 7 - brake pads; 8 - support; 9 - casing of the brake disc; 10 - brake pad mounting pins; 11 - fitting; 1 2 - connecting tube; 13 - brake disc.

Before installing the pads, make sure that the brake disc 13 is not damaged or has very deep scratches. If the disc is worn to a thickness of less than 9 mm, replace it with a new one.

To install the pads, move the pistons 3 as deep as possible into the cylinders 6. At the same time, make sure that the rubber protective seals of the pistons are in their sockets and are not damaged. Replace seals if necessary. As the pistons move into the cylinders, the fluid level in the reservoir rises. To avoid overfilling, remove the lid and take the required amount of liquid in a timely manner. Then install pads 7, insert pins 10 with springs 5, put cotter pins 4 and springs 2.

After replacing the pads, it is not necessary to bleed the brake system. Pumping is necessary only after dismantling the caliper 8 or the presence of air in the brake system and is carried out through the fitting 11.

The adjustment necessary to compensate for lining wear is made automatically.

Rear drum brakes

Every 20,000 km run, check the condition of the rear brake pads, for which:

- park the vehicle on a level surface and place chocks under the wheels;

- remove the car from the parking brake and loosen the rear wheel mounting bolts;

- install a jack and remove the wheel;

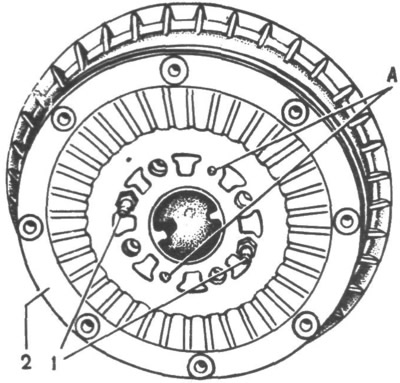

- remove the brake drum 2 (pic. 57), for which unscrew two bolts 1, insert them into the technological holes «A» and wrap until the drum separates.

Pic. 57. Brake drum:

1 - bolts; 2 - brake drum; A - technological holes.

Removal and installation of the brake drum is greatly facilitated if an autopreparation is applied to the gap between the hub and the drum «Unisma-1» with an exposure after application of 10-15 minutes.

Check the condition of the brake pads 2 (pic. 58) with friction linings 1 and the working surface of the brake drum. If the pads are broken or deformed, as a result of which uniform contact of the pads with the drum is excluded and braking efficiency is reduced, replace them with new ones. Replace the pads even if the thickness of the pads decreases to 2 mm. Replace pads only in pairs. The gap between the pads and drums is restored automatically as the linings wear.

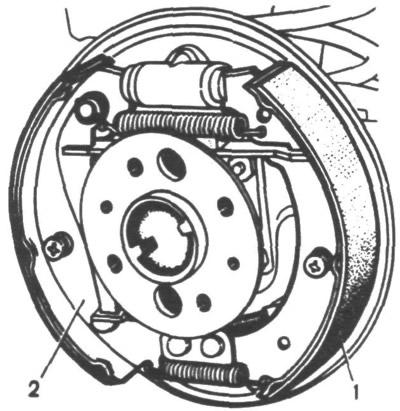

Pic. 58. Rear brake with drum removed:

1 - friction lining; 2 - brake block.

If deep grooves have formed on the working surface of the drum or the surface has become excessively oval, the drums must be bored and ground at a service station. Lubricate the landing belt with a thin layer of graphite grease before installing the drum.

When checking the rear brakes, do not forget to pay attention to the condition of the protective rubber boots of the brake cylinders.

Bleeding the brake system

Increased travel of the brake pedal and its «softness» indicate the presence of air in the brake system, which significantly reduces the effectiveness of the brakes. Bleed the brake system with two people. In the process of pumping, in order to eliminate the influence of the pressure regulator, it is not allowed to hang out the rear of the car.

Remove air from the system by pumping sequentially the brake cylinders, first the rear circuit, and then the front, as follows:

1. Remove the tank cap (pic. 55) and add brake fluid, bringing its level to normal.

2. Remove protective caps from fittings 11 (pic. 56) and 1 (pic. 59) and wipe the fittings with a clean cloth. Put the rubber hose from the accessory kit on the end of the fitting, and immerse the other end of the hose in a clean transparent vessel partially filled with brake fluid,

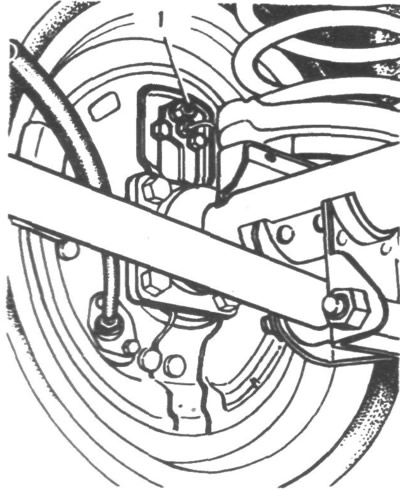

Pic. 59. View of the drum brake shield from the rear axle:

1 - fitting for bleeding the hydraulic system of the rear brakes.

3. Press the brake pedal sharply 3-5 times with an interval between pressing 2-3 s and, holding the pedal depressed, unscrew the fitting by 1/2-3/4 turn, pushing the pedal out of the system along with air through hose to vessel. After the brake pedal reaches the extreme forward position and the outflow of fluid through the hose stops, wrap the fitting.

4. Repeat step 3 until no more air bubbles come out of the hose. While holding the brake pedal down, tighten the fitting until it stops, remove the hose, wipe the end of the fitting dry and put on a protective cap.

During pumping, make sure that the fluid level in the tank is sufficient. At the end of pumping the system, restore the required maximum level in the tank.

The fluid released from the brake system during pumping is not recommended to be used in the future.

If the brake system is not pumped well enough, then when you press the brake pedal, an increased pressure will be felt at the end of its stroke «softness», the greater, the more air remains in the system. If it is impossible to completely remove air through one fitting, repeat pumping simultaneously through two fittings for each pair of wheels.

Brake Fluid Replacement

To replace the brake fluid with fresh:

- install the car on a lift or viewing hole;

- remove the protective caps from the fittings, put rubber hoses on the fittings, lower the second ends of which into transparent vessels;

- unscrew the fittings by 1/2-3/4 turns and ask the assistant to sharply press the brake pedal and slowly release it. Thus, the liquid from the system will flow into the vessels. As the fluid stops flowing, tighten all fittings in sequence. Drain the fluid from the vessels, fill the reservoir with fresh brake fluid and unscrew the fittings;

- again ask the assistant to sharply press the brake pedal and release it smoothly, and also monitor the fluid level in the reservoir, preventing «dry» bottom;

- when liquid appears in the vessel, tighten all fittings in sequence;

- bleed the brake system as described above.

Brake pedal free travel adjustment

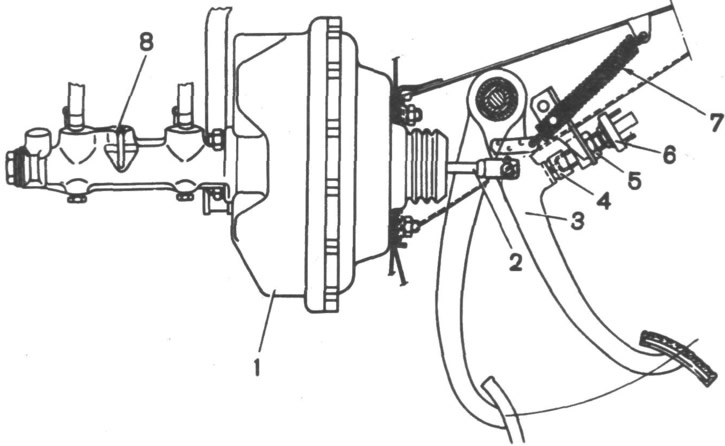

The free travel of the brake pedal with a working brake system and the engine not running should be 3-5 mm. Adjust it by moving switch 6 (pic. 60) brake light together with buffer 4 with nut 5 previously unscrewed. After adjustment, tighten nut 5.

Pic. 60. Brake pedal:

1 - vacuum amplifier; 2 - pusher; 3 - brake pedal; 4 - brake light switch buffer; 5 - thrust screw nut; 6 - stoplight switch; 7 - pedal release spring; 8 - the main cylinder of the hydraulic system of the brakes.

Vacuum brake booster

Every 30,000 km run, check the performance of the vacuum booster, for which:

- press the brake pedal 5-6 times with the engine off;

- while holding the brake pedal down, start the engine. With a working booster, the brake pedal after starting the engine should «go ahead». If this does not happen, check the tightness of the hose connections to the intake pipe and to the amplifier, since loosening of the fasteners causes air leakage and drastically reduces the efficiency of the amplifier. If the problem persists after this, contact a service station.

Pressure regulator

Every 30,000 km run, check the operation of the pressure regulator, for which:

- put the car on a lift or viewing hole;

- clean the regulator and cover from dirt;

- carefully remove the cover, remove any remaining grease and clean the connection «torsion lever - regulator piston»;

- ask the assistant to sharply press the brake pedahp a working pressure regulator, the protruding part of the piston will move relative to the body, turning the torsion lever;

- repeat the operation 2-3 times and, after making sure that the regulator is working, put 5-6 g of fresh grease DT-1 and put on the cover.

If the piston does not move relative to the body, contact a service station.

Parking brake

Every 20,000 km run, and on a new car after running the first 2000-3000 km, check and, if necessary, adjust the stroke of the parking brake lever.

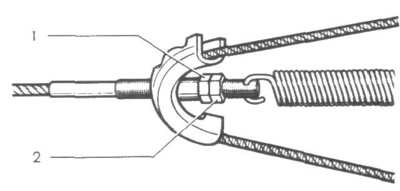

Proper adjustment of the parking brake ensures reliable operation of the vehicle's braking system. If the car is not braked by the parking brake on a slope of up to 30% when the lever is moved by 4-5 teeth of the sector, adjust the stroke of the lever with the tensioner. To adjust:

- move the lever to the lowest position and lift it up by two teeth of the sector;

- release locknut 2 (pic. 61) and, turning the adjusting nut 1, tighten the cable;

- tighten lock nut 2 and check whether the car remains in the braked state when the lever is moved 4-5 teeth.

Pic. 61. Adjusting the stroke of the parking brake lever:

1 - adjusting nut; 2 - locknut.

To prevent brake pads from freezing to the drums after driving on wet roads with sudden temperature fluctuations, do not apply the parking brake when the car is parked in an open area or in an unheated garage, do not «having dried» brakes with smooth braking when moving to a parking lot.