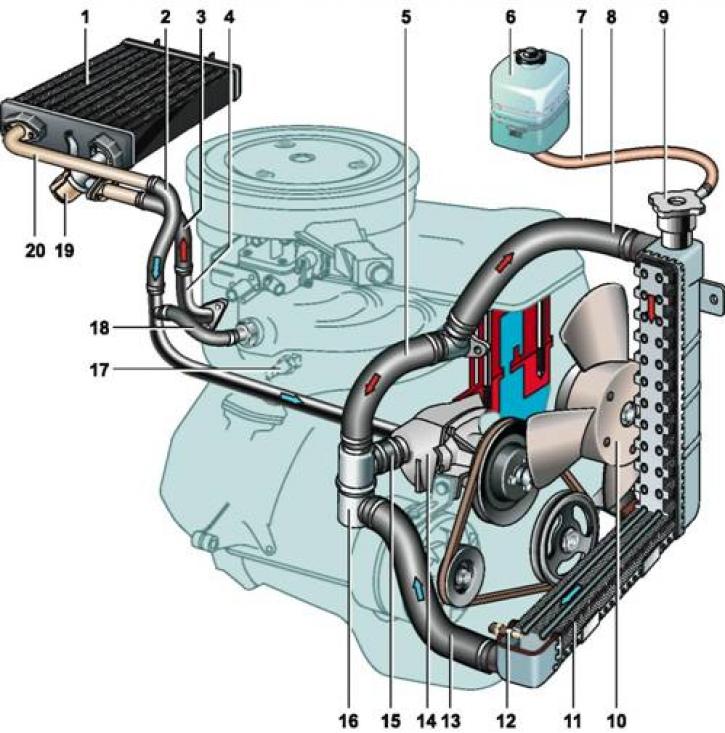

Details of the carburetor engine cooling system: 1 - heater radiator; 2 - hose for draining coolant from the heater radiator; 3 - hose for supplying coolant to the heater tap; 4 - pipe for draining coolant from the cylinder head; 5 - bypass hose; 6 - expansion tank; 7 - connecting hose of the expansion tank; 8 - hose for supplying coolant to the radiator; 9 - radiator cap; 10 - radiator electric fan; 11 - radiator of the cooling system; 12 - sensor for turning on the electric fan; 13 - coolant outlet hose from the radiator; 14 - coolant pump; 15 - hose for supplying coolant to the pump; 16 - thermostat; 17 - coolant temperature indicator sensor; 18 - hose for draining coolant from the inlet pipeline; 19 - heater valve; 20 - pipe for draining coolant from the heater radiator

The cooling system maintains the optimal thermal regime of the engine by controlled heat removal from the most heated parts. The engine cooling system is liquid, sealed type, with forced circulation of the coolant and an expansion tank.

connected to the cooling system interior heater radiator car. The heated coolant from the cylinder head enters through a hose through an open valve into the heater radiator, and then (through the fluid outlet) - to the coolant pump.

coolant pump - centrifugal, driven by a V-belt drive from the crankshaft pulley. The pump consists of a housing and a cover made of aluminum alloy. The cover is fastened with nuts to four studs screwed into the pump housing. A sealing gasket is installed between the body and the cover. The pump shaft rotates in a double-row sealed bearing. A pump drive pulley flange is pressed onto the front end of the roller, and a cast-iron or plastic impeller is pressed onto the rear end.

Radiator - vertical, tubular-lamellar, with two plastic tanks and an aluminum core. The radiator is mounted on two rubber pads and is attached to the body with two bolts. The filler neck of the radiator is hermetically sealed with a stopper and connected with a hose to expansion tank. The radiator cap has an outlet (steam) a valve pressed by a spring to the landing belt of the filler neck, and an inlet valve through which the radiator is connected to the expansion tank. The inlet valve is not pressed against the seat and has a gap of 0.5-1.1 mm, which ensures the inlet and outlet of coolant into the expansion tank during heating or cooling. With a sharp increase in temperature or liquid boiling, the inlet valve does not have time to release liquid into the expansion tank and closes, separating the system from the expansion tank. When, due to further heating of the liquid, the pressure increases to 50 kPa, the outlet valve opens and part of the liquid begins to flow into the expansion tank. The expansion tank is closed with a stopper with a rubber valve that maintains pressure in the tank close to atmospheric.

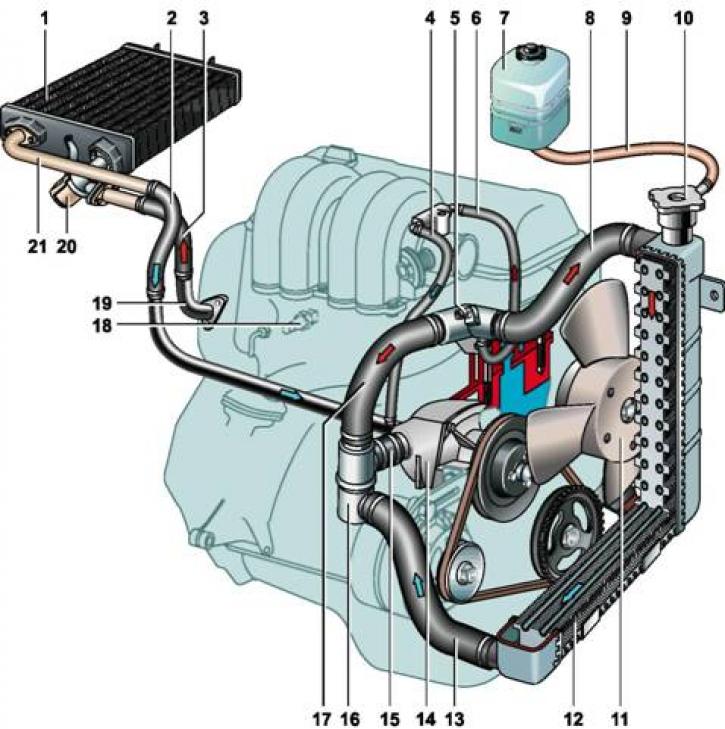

Details of injection engine cooling system: 1 - heater radiator; 2 - hose for draining coolant from the heater radiator; 3 - hose for supplying coolant to the heater tap; 4 - hose for draining coolant from the throttle body heating unit; 5 - sensor (control systems) coolant temperature; 6 - hose for supplying coolant to the throttle body heating unit; 7 - expansion tank; 8 - hose for supplying coolant to the radiator; 9 - connecting hose of the expansion tank; 10 - radiator cap; 11 - radiator of the cooling system; 12 - radiator electric fan; 13 - coolant outlet hose from the radiator; 14 - coolant pump; 15 - hose for supplying coolant to the pump; 16 - thermostat; 17 - bypass hose; 18 - coolant temperature indicator sensor; 19 - coolant outlet pipe from the cylinder head; 20 - heater valve; 21 - coolant outlet pipe from the heater radiator

electric fan installed behind the radiator. To reduce noise during operation, the fan impeller blades have a variable installation angle and pitch along the radius. The electric fan of the carburetor engine is turned on from a sensor screwed into the lower part of the right radiator tank. On cars of early releases with constant forced ventilation, the fan switch-on sensor and the electric fan were not installed. The fan impeller was attached to the coolant pump pulley and rotated constantly while the engine was running. On the injection engine, the electric fan is controlled by ECU commands (via relay). The initial data for these commands is the signal of the coolant temperature sensor installed in the outlet pipe of the cooling system.

Thermostat The cooling system serves to maintain the required thermal regime of the engine and accelerate its warm-up. When the coolant temperature is below 80°C, the main thermostat valve is closed and the bypass valve is open. Fluid circulates from the cylinder block cooling jacket through the thermostat bypass valve to the pump, which again supplies fluid to the cooling jacket, bypassing the radiator (small circle). This ensures that the engine warms up quickly. The temperature at which the main thermostat valve opens should be in the range of 80.6-81.5°C. The total stroke of the main valve must be at least 6 mm. When the liquid is heated above 94°C, the main thermostat valve opens completely, and the bypass valve closes. The liquid comes from the cooling jacket through the inlet hose to the radiator. From the radiator, the fluid passes through the outlet hose through the main thermostat valve to the pump, which again supplies fluid to the cooling jacket (big circle). In the temperature range of 80-94°C, the thermostat valves are in an intermediate position and the liquid circulates both in a small and a large circle. Regardless of the position of the thermostat valves, when the heater tap is open, the liquid always circulates through the heater radiator. In addition, fluid is constantly circulated through the intake manifold or throttle body heating assembly (on injection engine).