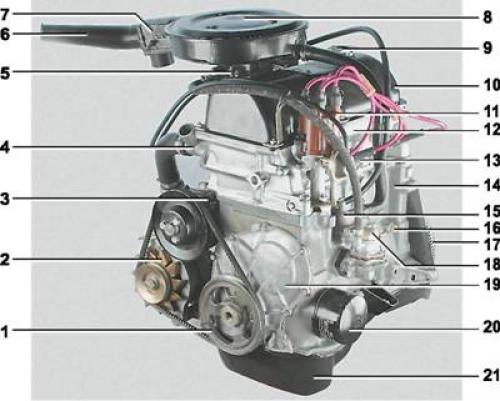

Carburetor engine: 1 - crankshaft pulley; 2 - generator; 3 - coolant pump; 4 - thermostat; 5 - carburetor; 6 - air intake; 7 - thermostat; 8 - air filter housing; 9 - oil filler cap; 10 - cylinder head cover; 11 - ignition distributor; 12 - cylinder head; 13 - coolant temperature indicator sensor; 14 - cylinder block; 15 - oil separator of the crankcase ventilation system; 16 - oil pressure sensor; 17 - flywheel; 18 - fuel pump; 19 - camshaft drive cover; 20 - oil filter; 21 - engine oil pan

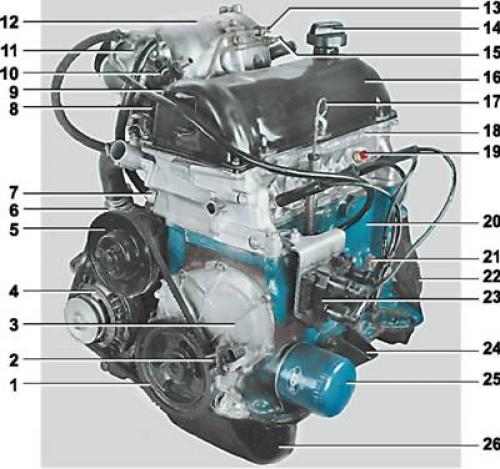

injection engine: 1 - crankshaft pulley; 2 - crankshaft position sensor; 3 - camshaft drive cover; 4 - generator; 5 - coolant pump; 6 - thermostat; 7 - chain tensioner; 8 - idle speed regulator; 9 - fuel rail; 10 - throttle position sensor; 11 - throttle body; 12 - receiver; 13 - fuel supply pipe; 14 - filler cap; 15 - drain fuel tube; 16 - cylinder head cover; 17 - oil level gauge (probe); 18 - cylinder head; 19 - coolant temperature indicator sensor; 20 - cylinder block; 21 - oil pressure sensor; 22 - flywheel; 23 - coil (module) ignition; 24 - engine support bracket; 25 - oil filter; 26 - engine oil pan

Depending on the modification, one of four engines can be installed on the car: 2103, 2104 (1.5 l) or 2106, 21067 (1.6 l).

Engine - gasoline, four-stroke, four-cylinder, in-line, eight-valve, with an overhead camshaft. Engines 2103 and 2106 are carbureted, and engines 2104 and 21067 are with multipoint fuel injection.

The 2104 engine was created on the basis of the 2103 engine, so the cylinder block, connecting rod and piston group, gas distribution mechanism drive and crankshaft have the same design and dimensions.

The 21067 engine was created on the basis of the 2106 engine. Since the 21067 and 2104 engines have different cylinder diameters, the pistons with rings are not interchangeable, respectively. The timing gear drive parts and crankshafts of these engines are identical.

On the cover of the camshaft drive of injection engines, brackets are made for installing the crankshaft position sensor.

Car engines equipped with an injection system comply with the EURO II exhaust gas toxicity standards. Multiport fuel injection with EVAP and catalytic converter reduces fuel consumption and makes it easier to start the engine in cold weather.

The ignition system of engines 2104 and 21067 is included in the control system. The functions of the ignition distributor are performed by the electronic engine control unit.

Cylinder block cast from ductile iron. The engine cylinders are bored in the block and honed. By diameter, the cylinders are divided into 5 classes through 0.01 mm and are marked on the lower plane of the block with the letters A, B, C, D and E. The cylinders are arranged vertically in one row.

Crankshaft, cast from high-strength cast iron, installed in the lower part of the block on five support necks. The shaft rotates in steel-aluminum liners, a layer of aluminum-tin alloy is applied to the steel base. The holes for the main bearings are machined together with the bearing caps, so the caps are not interchangeable. On the outer surfaces of the caps of the main bearings, marks are made corresponding to their serial number (counting from the front end of the crankshaft). To prevent axial movement of the crankshaft, two thrust half rings are installed in the grooves of its rear support - steel-aluminum and metal-ceramic. The front crankshaft oil seal is installed in the camshaft drive cover, "working" along the outer surface of the pulley. The rear oil seal is pressed into a holder attached to the cylinder block, and "works" on the surface of the crankshaft flange. The front bearing of the input shaft of the gearbox is pressed into the rear end of the crankshaft.

connecting rod - steel, forged. The lower head of the connecting rod is detachable, and connecting rod bearings are installed in it. The hole in the bottom head of the connecting rod is processed together with the cap, so the caps are not interchangeable. In order not to confuse the connecting rod caps, the numbers of the cylinders in which they are installed are marked on the sides of the connecting rods and caps.

A piston pin is pressed into the upper head of the connecting rod, which rotates freely in the piston bosses.

Pistons cast from aluminum alloy, and their outer surface (to improve run-in to cylinder walls) coated with tin. Piston skirt (to compensate for uneven thermal expansion) It has a complex geometric shape: it is conical in height and oval in cross section. Therefore, the piston diameter should be measured in a plane perpendicular to the piston pin, at a distance of 52.4 mm from the piston crown. The axis of the hole for the piston pin is shifted to the right of the axis of symmetry of the piston. Piston rings made of special cast iron are installed in the piston grooves. Closer to the bottom of the piston are two compression rings, and to the skirt - one oil scraper. The upper compression ring has a convex working surface coated with porous chrome, and the lower one is phosphated, scraper type. The oil scraper ring is two-component: it consists of a ring and an expander. The working surface of the ring is chrome-plated.

cylinder head cast from aluminum alloy and attached to the block with eleven bolts. A non-shrink gasket is installed between the head and the block. Seats and valve guides made of cast iron are pressed into the block head. On top of the valve guide bushings, oil deflector caps are pressed, which are necessary to reduce the flow of oil into the combustion chamber through the gaps between the stem and the guide bushing. The valves are made of heat-resistant steel and are actuated (through leverage) camshaft rotating in an aluminum bearing housing.

Camshaft - five-bearing, eight-cam, cast iron. The shaft is held against axial movement by a support flange. A driven sprocket is installed on the front end of the shaft. The drive of the camshaft and the roller of auxiliary units is carried out from the crankshaft drive sprocket by a double-row roller chain. The drive is equipped with a damper and a chain tensioner with a shoe.

Flywheel mounted on the rear end of the crankshaft and attached to it with six bolts. The flywheel is cast iron, with a pressed ring gear, necessary for starting the engine with a starter. When assembling a new engine, the flywheel is balanced along with the crankshaft.