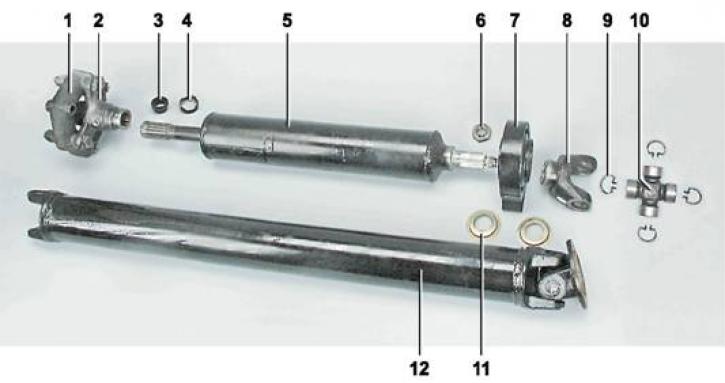

Driveline details: 1 - elastic coupling (2101-2202120); 2 - front propeller shaft flange (2101-2202023); 3 - flange gland (2101-2202110); 4 - stuffing box holder (2101-2202115); 5 - front propeller shaft (21012202015); 6 - fork fastening nut (2101-2202105); 7 - intermediate support (2101-2202080); 8 - fork of the front propeller shaft (2101-2202022); 9 - retaining ring (2101-2202043 - with a thickness of 1.50 mm); 10 - cross with bearings (2101-2202025); 11 - mud deflector (2101-2202103); 12 - rear driveshaft (2101-2201014)

The cardan gear is designed to transmit torque from the secondary shaft of the gearbox to the drive gear of the rear axle gearbox, regardless of its position relative to the car body (within rear suspension travel).

The driveline consists of two shafts (front and rear), two cardan joints, an elastic coupling and an intermediate support.

A flange fixed with a nut is installed on the splines of the secondary shaft of the gearbox. With six bolts, through a rubber elastic element, it is connected to a similar flange, assembled with which it forms elastic coupling. The second flange also has a splined hole into which a splined tip welded to the front shaft is loosely inserted.

Shaft made of a steel pipe, a second splined tip is welded to its opposite end, which rests on the bearing of the intermediate support.

On the splines of the tip, the fork of the front cardan joint.

The joint consists of two forks, a cross and four needle bearings with blind bottoms and radial-face seals to protect against water and dirt, as well as to prevent leakage of lubricant. The bearings are fixed against axial displacement in the lugs of the forks by spring retaining rings.

The other front yoke is welded to the rear driveshaft. This shaft is also made of a steel pipe, at its rear end there is a second cardan joint of a similar design, the rear fork of which has a flange connected by four bolts and nuts to the flange of the drive gear shank of the rear axle gearbox.

intermediate support consists of a steel bracket with a rubber elastic corrugated cushion vulcanized to it, inside which a steel sleeve-body is placed. The housing is equipped with a ball radial bearing of a closed type, additionally protected by mud-reflecting washers.

The cardan drive is dynamically balanced as an assembly using balancing weight plates welded to the outer surface of the shafts.

To prevent a vehicle accident "cliff" front propeller shaft (for example, the destruction of the elastic coupling) on the bottom of the body there is a safety bracket that prevents the shaft from falling onto the road.

While the car is moving, the distance between the rear axle and the gearbox is constantly changing. The design of the driveline allows you to compensate for this change due to the movable splined connection of the front shaft with the flexible coupling flange. The rubber cushion of the intermediate support due to its configuration does not prevent the axial displacement of the front shaft. Angular movements of the rear shaft are provided by cardan joints. The elastic coupling smooths out torque fluctuations and compensates for small angular deviations of the front shaft. In addition, the clutch and elastic intermediate support dampen noise and vibrations that occur when the vehicle is moving.

The maintenance of the cardan transmission is reduced to periodic lubrication of the movable spline connection, for which a hole is made in the flange of the elastic coupling, which is closed by a threaded plug. The rubber seal prevents leakage of grease and dirt from entering the joint. Pivot bearings are lubricated during assembly only (bearing replacement). The bearing of the intermediate support is also lubricated for its entire service life and no relubrication is provided.