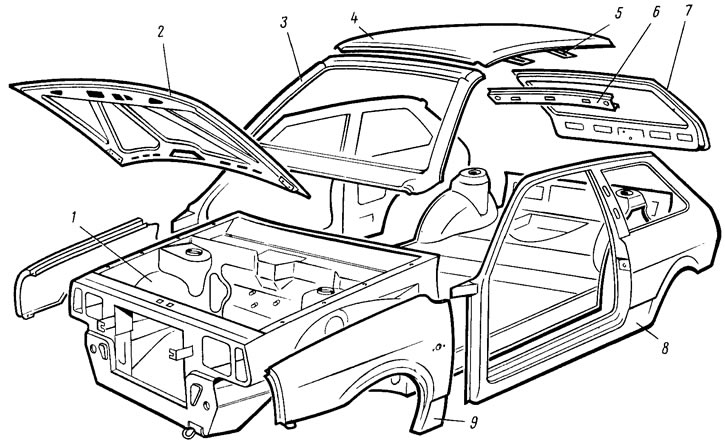

Pic. 158. The main elements of the body frame

The main elements of the frame are the front 1 (pic. 158), floor, sidewalls 8, roof 4 with frame 3 of the wind window, rear panel and load-bearing elements (spars, cross members, racks). The following are hung on the frame: wings 9, hood 2, side doors and rear door 7.

All parts and components of the body, except for attachments, are joined into a single whole by resistance spot welding, and heavily loaded parts are additionally welded by electric arc welding.

The front end 1 consists of a vertical front end shield, mudguards of the front fenders, front spars, cross members and an air intake box. The floor of the body consists of three main parts: the front, middle and rear floor panels. The front panel of the floor is trough-shaped, in the middle it has a tunnel for exhaust pipes and pipelines. The rear floor panel has a one-piece stamped niche for a spare wheel installed from the trunk. Two spars run along the entire floor, which form single longitudinal hidden cavities ventilated with air with the front and rear spars. In general, the floor has front, middle and rear crossbars.

The outer panels of the sidewall are made in whole parts with central and rear pillars, with openings for the side window and the front door. The inner sidewall panels are also made in one piece along with the outer arches (mud flaps) rear wheels. At the rear, the sidewalls have amplifiers and a niche for a gasoline vapor separator, as well as grooves and flanges for tailgate seals. The frame of the wind window is made in one piece, to which amplifiers are welded at the top and bottom. The front struts form two isolated cavities to increase rigidity. The roof panel has reinforcements 5, a front beam and a rear beam 6 for hanging the tailgate. The back panel has top and bottom cross members.

The main body parts are stamped from mild steel sheet 08kp. For deep-drawing parts during stamping and better weldability, steel 08Yu is used, and for greater tensile strength, low-alloy steel 08GS is used. The thickness of the main panels is 0.8 mm; for outer panels of doors and front fenders 0.7 mm; for amplifiers 1-1.2 mm; for front spars 1.8 mm. The remaining spars have a thickness of 1 mm. Various small body parts (connectors, brackets, extensions) are stamped from steel with a thickness of 0.8-2.5 mm.

To increase the anti-corrosion resistance, the inner surface of the wing has a zinc-metal coating 0.1 mm thick and an additional coating with D-11 A plastisol. The wing is attached to the body frame with eight self-tapping bolts. Insulating pads are installed under the front fenders.

Body frame parts most susceptible to corrosion (radiator frame, radiator frame cross member, bulkhead connectors, middle and rear cross members, front door sill divider and a number of other details), are made of steel with one- or two-sided zinc-metal coating.