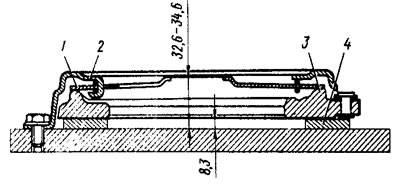

To check the condition of the leading part of the clutch, cover 2 is installed (pic. 59, 1 clutch assembly with pressure plate 3 on a tool with an intermediate ring 4 8.3 mm thick. This device simulates a flywheel with a driven disk. Having fixed the clutch cover, perform three shutdown strokes, applying a load of no more than 137.8 kgf to the petals of the pressure spring 1, and measure the amount of pressure plate withdrawal. Shutdown progress (7±0,1) mm ends of the petals must correspond to a disk stroke of at least 1.4 mm.

Pic. 59. Clutch control

Measure the distance from the base of the fixture to the plane of the ends of the spring petals. It should be 32.6-34.6 mm for a new clutch. In the process of clutch operation, due to the wear of the clutch discs, this size increases. If it reaches 43 mm or the movement of the pressure plate is less than 1.4 mm, replace the clutch cover assembly with the pressure plate.

Check the elasticity of the springs. Clutch release fork return spring must have a length of: 102 mm under force (23,5±2,4) kgf; 91 mm under force (12,3±1,2) kgf; 81 mm free.

The length of the clutch booster spring must be 30.6 mm under force (54,9±0,6) kgf; 44 mm under force (31,5±0,7) kgf; 62 mm free.

Check the condition of the cable. First of all, make sure that the ends of the cable, the leash and the earring are firmly attached, and that the cable moves freely inside the sheath. Check the condition of the cable sheath, rubber buffers and bushings, protective cover, earring and leash. If the cable and its other elements are damaged, if the tips are loosened, the cable is replaced with a new one.

The dimensions of the main mating parts and the limits of permissible wear in operation are given in Table. 6.