Disassembly of the outer hinge

Disassembly of the hinge is carried out only in case of damage to the protective cover 8 (see fig. 76), when it becomes necessary to change the lubricant.

To disassemble the outer hinge, remove clamps 5 and 9 with tool 67.7814.9508 and slide the protective cover 8 along the wheel drive shaft (at the drive of the right wheel, the cover is pressed in or turned out).

Using a drift and a hammer, the hinge is knocked off the shaft, applying force to the holder 3. Then the hinge is washed.

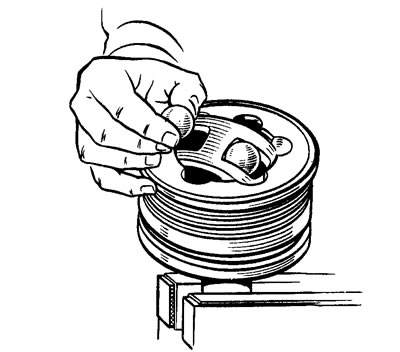

Before disassembling with paint or a touchstone, mark the relative position of the clip 3 (pic. 77), separator 2 and body 1 of the hinge. Fix the outer hinge in a vise, as shown in Fig. 78. Tilt the cage and separator so that one ball comes out of the groove of the hinge body as completely as possible. With a screwdriver made of soft material, squeeze the ball out of the separator. Then all the parts are turned so that the adjacent ball takes the same position, and it is removed from the separator.

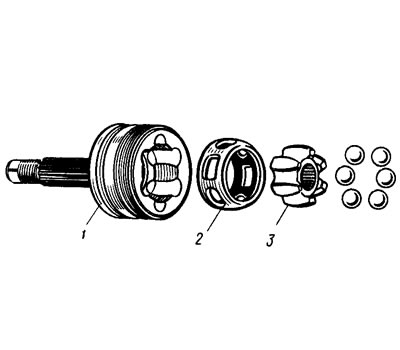

Pic. 77.. External hinge parts |

Pic. 78. Removing the balls from the separator |

Using these techniques, take out the remaining balls.

The sequence of removing the balls can be different - through one ball. Slight tapping on the separator or cage with an object made of soft material is allowed. Excessive force of rotation of the separator is unacceptable, as it is possible to block the balls, which will complicate further disassembly.

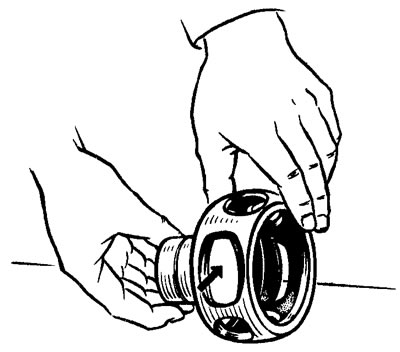

Install the separator with the cage so that the elongated windows of the separator (marked with arrows in Fig. 79) located against the protrusions of the hinge body and take out the separator assembly with the clip. The cage is removed from the separator, for which one of the projections of the cage is placed in the elongated window of the separator (pic. 80) and roll out the clip. Once again, the hinge parts are thoroughly washed and the condition of all parts is checked, paying special attention not only to their wear and damage, but also to the presence of corrosion. If the working surfaces are worn more than 0.1 mm, damaged or corroded, the hinge assembly is replaced.

Pic. 79. Removing the separator assembly with the cage from the hinge body |

Pic. 80. Extraction from the clip separator |

Assembling the outer hinge

The assembly of the outer hinge is carried out in the reverse order of disassembly, taking into account the following:

- before assembly, grease SHRUS-4 is applied to all parts;

- when installing the separator assembly with the cage into the hinge body, it is necessary to ensure that the marks made before disassembly coincide;

- when installing the balls in the separator, the cage is tilted approximately at an angle that is 2 times greater than the separator;

- fill the hinge with SHRUS-4 grease in the amount of 40 cm3;

- install a new retaining ring in the groove of the shaft strictly in its center, using grease. Then the shaft rests against the cage so that the alignment of the ring relative to the shaft and the cage is preserved. Sharply hit the end of the wheel drive shaft. In this case, the retaining ring is compressed and slips through the hole of the clip;

- before installing the inner clamp, air is released from the boot, for which the seating belt of the boot is pulled away from the drive shaft with a screwdriver, check for cracks and deformations in the zone of the clamp nests. If they are found, replace the clamps with new ones using tool 67.7814.9508;

- when installing the clamp lock, the top of the fixing tooth is placed in the direction of rotation of the hinge.

Disassembly of the inner joint

Disassembly sequence:

- remove clamps 5 and 9 (see fig. 76) tool 67.7814.9508 and shift the protective cover 8 along the shaft (at the drive of the right wheel, the cover is pressed in or turned out);

- mark the relative position of the parts to be separated;

- latch 11 is removed from the hinge body, and then shaft 10 is assembled with holder 3, separator 6 and balls 4;

- with a screwdriver made of soft material, remove the balls and remove the clip from the separator;

- using the above methods (see «Disassembly of the outer hinge»), disconnect the hinge parts, wash them and carefully check the condition of all parts. If the working surfaces are worn more than 0.1 mm, the parts are damaged or corroded, the hinge assembly is replaced.

Inner Hinge Assembly

The assembly of the inner hinge is carried out in the reverse order of disassembly. In this case, before installing the cage on the shaft splines, make sure that the annular groove of the cage for the thrust ring is installed towards the shaft. After assembly, make sure that the cage assembly with the separator and balls moves freely along the entire length of the housing grooves from the force of the hand. Otherwise, the cause of jamming is identified and, if parts are damaged, the hinge assembly is replaced. Then, after making sure of the correct assembly, they put 80 cm into the hinge3 SHRUS-4 lubricants.

Before installing the clamps, they release «excess» air from the boot by pulling the seat band of the boot away from the drive shaft with a screwdriver.