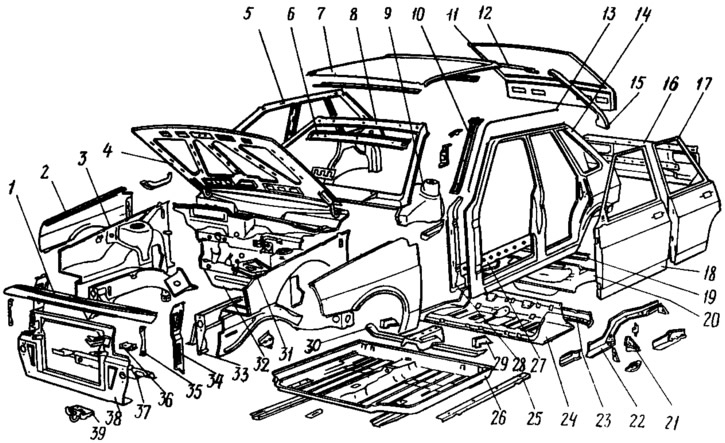

Pic. 136. Details of the car body frame VAZ-2109:

1 - the upper cross member of the radiator frame; 2 - front wing; 3 - mudguard of the front wing; 4 - hood; 5 - inner side panel; 6 front lower roof beam; 7 - roof panel; 8 - wind window frame; 9 - inner arch of the rear wheel; 10 - inner pillar of the wind window frame; 11 - tailgate; 12 - rear roof beam; 13 - drain groove; 14 - outer panel of the sidewall; 15 - groove for the opening of the tailgate; 16 - back panel; 17 - back door; 18 - front door; 19 - rear cross member of the floor; 20 - rear panel of the floor; 21 - reinforcement of the spar under the rear suspension arm; 22 - rear spar of the floor; 23 - middle cross member of the floor; 24 - middle floor panel; 25 - amplifier for installing a jack; 26 - front floor panel; 27 - lower lining of the sidewall; 23 - front strut amplifier; 29 - front seat bracket; 30 - front cross member of the floor; 31 - platform battery; 32 - front panel; 33 - front spar; 34 - radiator frame bracket; 35 - bracket for mounting the headlight; 36 - bracket for the front suspension of the power unit; 37 - lower cross member of the radiator frame; 38 - radiator frame panel; 39 - reinforcement of the lower cross member with an eye for towing.

All parts and components of the body, except for hinged units and front fenders, are joined into a single whole by resistance spot welding, and heavily loaded parts are additionally welded by electric arc welding. Due to the reduction in the number of body parts and the use of large-sized panels, the number of welding points is reduced by almost two times compared to the car body VAZ-2101. The use of electric arc welding has also been significantly reduced.

The front end of the body consists of a vertical front panel 32, mudguards 3 and an air intake box. Mudguards have front spars 33.

The body floor includes three main parts: front 26, middle 24 and rear 20 floor panels. The front panel of the floor is trough-shaped, in the middle it has a tunnel for exhaust pipes, fuel lines and pipelines, which protects them from damage. The back panel of a floor has an all-stamped niche for a spare wheel. Spars are welded along the entire floor, which form longitudinal hidden cavities along the entire vehicle with the front and rear spars. Front 30, middle 23 and rear 19 crossbars are welded to the floor.

Sidewalls consist of external 14 and internal 5 panels. The outer panels of the sidewalls are made as one unit with the front, center and rear pillars of the VAZ-2109 car, the front and center pillars of the VAZ-2108. The inner sidewall panels are also made integral with the outer arches of the rear wheels and with the strut reinforcements. Behind the sidewalls have amplifiers and a niche (at the right side) for gasoline vapor separator, as well as grooves and flanges for door seals.

Frame 8 of the wind window is stamped as one piece, to which reinforcements are welded at the top and bottom. The front pillars of the frame with amplifiers to increase rigidity form two isolated cavities.

The roof panel 7 has two amplifiers, behind the beam 12 for hanging the tailgate 11.

Rear lights are attached to the rear panel 24 with upper and lower crossbars.

The plumage of the body includes the front fenders 2, the outer panels 14 of the sidewalls, the frame 8 of the wind window, the roof panel 7 and the rear panel 16.

The main body parts are stamped from low-carbon cold-rolled steel sheet. The thickness of the sheet material of body parts is mainly 0.8 mm; outer panels of doors and front fenders - 0.7 mm; amplifiers - 1... 1.2 mm. The front spars 33 are 1.8 mm thick; other spars - 1.0 mm. Various small body parts (connectors, brackets, extensions) are stamped from steel with a thickness of 0.8... 2.5 mm.

Removable units are hung on the body: front doors (rear for VAZ-2109), tailgate 11, hood 4, front fenders 2, bumpers, radiator lining and others.

The front fenders are attached to the body frame with eight self-tapping bolts: four on the upper flange of the wing to the mudguard, one bolt each at the front bottom and rear bottom and two bolts to the A-pillar (under the wing). Gaskets are installed under the front fenders to reduce vibration.

The radiator lining is made of microporous polyurethane foam with the addition of 20% finely ground glass fiber. The cladding is painted to match the body color, fastened with screws to the body at the bottom at the ends, front and top under the hood.

Body parts that are most susceptible to corrosion are made of steel with a one-sided or two-sided zinc-metal coating. These include the radiator front frame, radiator frame lower cross member, bulkhead connectors, floor center and rear cross members, door sill separator (on both sides), front fenders and a number of other small details.