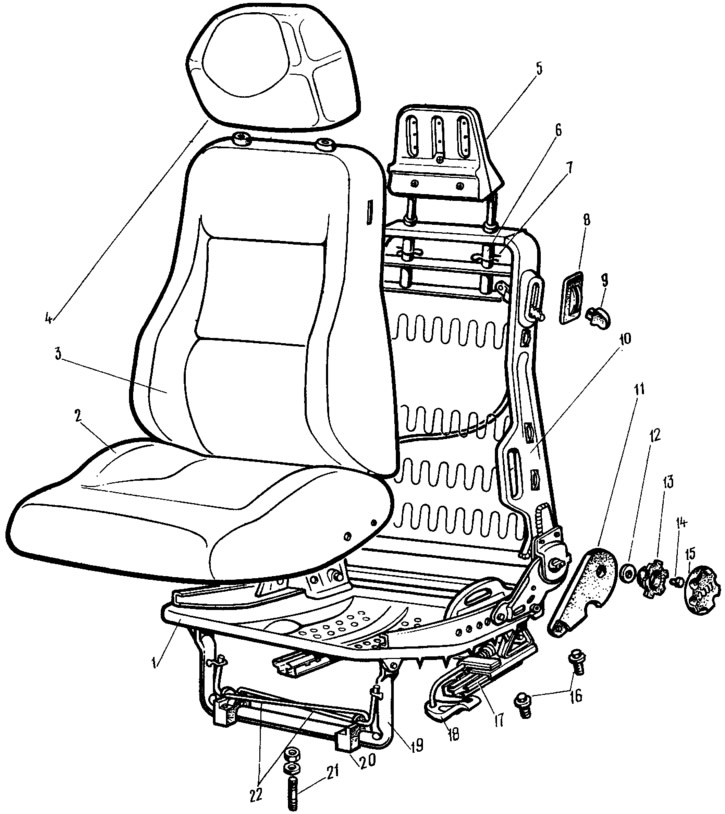

Pic. 153. Front seat:

1 - pillow base; 2 - pillow; 3 - back; 4 - headrest; 5 - head restraint frame; 6 - headrest guide; 7 - cotter pin; 8 - lining of the backrest tilt lever; 9 - handle of the backrest reclining mechanism; 10 - base of the back; 11 - lining of the mechanism for adjusting the inclination of the back; 12 - gasket; 13 - holder for the handle of the backrest adjustment mechanism; 14 - holder fastening bolt; 15 - handle of the backrest tilt adjustment mechanism; 16 - slide mounting bolt; 17 - slide guide; 18 - handle of the movement mechanism; 19 - base stand; 20 - front bracket; 21 - bracket fastening pin; 22 - torsion bars.

The base 1 of the cushion 2 of the seat consists of a strong steel frame and a cushion tray made of pressed sheet steel. An amplifier is welded to the pallet. The base 10 of the backrest is made of strong steel frames to which wire springs are attached. To avoid creaking, the ends of the springs are covered with a layer of polyamide resin. The base of the backrest is pivotally connected to the base 1 of the pillow by the lower links of the tilt adjustment mechanism.

Guides 6 of the headrest 4 are welded to the base 10 of the backrest. The frame 5 of the headrest is stamped from sheet steel and fastened with two stoppers in the form of clamps on the round post of the headrest. The ends of the racks have three stamped recesses for fixing the headrest with cotter pins 7, each of which is pressed into one of the recesses through a slot in the guide. The headrest is manually adjustable both in height and angle of inclination by turning on the rack around the horizontal axis. From below, the headrest is closed with a plastic lining, fastened with two screws.

Cushion 2, backrest 3 and headrest 4 of VAZ-2108 and 21081 vehicles have polyurethane foam padding, padding and upholstery. The upholstery is made of a composite knitted material «Grabotina» or caprovelour. Its color is selected depending on the color of the body.

On VAZ-21083 cars, as well as on VAZ-2109 and 21093, the front seats differ mainly in individual elements of the cushion and back upholstery.

Each of the front seats of the cars in question and their modifications has mechanisms: moving the seat forward and backward, adjusting the backrest, tilting the backrest forward.

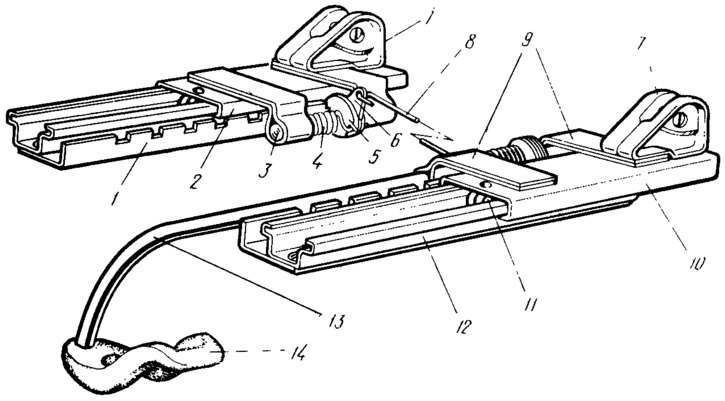

The mechanism of movement of the seat has a sled (pic. 154), consisting of guides 12 and sliders 2 and 10, which are stamped from sheet steel. The rails are bolted to the rear body brackets. The sliders can move along the guides, each on two rollers 11. To protect the rollers from falling out and limit their convergence, stampings are provided on the lower plane in its middle part and at the ends. The sliders have vyshtampovki at the rear ends. Rubber rings are installed in the annular grooves of the rollers. The displacement of the sliders up and to the sides is limited by the edges of the sliders and guides. The sliders are pivotally connected to the base of the pillow.

Pic. 154. Front seat sled:

1 - latch of the mechanism for moving the internal sled; 2, 10 - sliders; 3 - axis of the latch of the internal slide; 4 - latch spring; 5 - latch; 6 - latch lever; 7 - staples; 8 - latch rod; 9 - latch brackets; 11 - roller; 12 - guide of the outer slide; 13 - rod of the handle of the movement mechanism; 14 - handle of the movement mechanism.

The seat is fixed in the desired position by latches 5, each of which is pressed by a spring 4 into one of the grooves of the comb latch 1 of the movement mechanism. The clamps are welded to the guides. The levers 6 of the latches of the inner and outer sleds are interconnected by a rod 8. The latch of the outer sled is mounted on a rod 13 with a handle 14 of the seat movement mechanism. By pressing the handle, the latches are disengaged from the comb latches and the seat is moved to the desired position. When the handle is released, the seat is fixed by latches under the action of springs. Consistency of the action of the latches of the inner and outer sled is achieved by bending the rod 8.

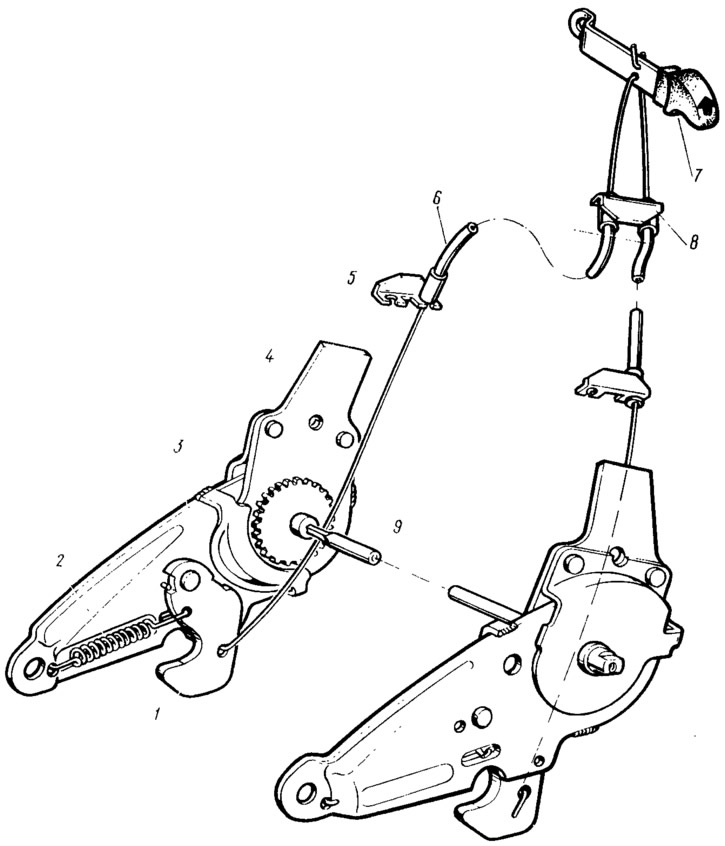

The mechanism for adjusting the inclination of the back allows you to turn the knob 15 (see fig. 153) mechanism to change the position of the back. To relax the driver or passenger, the front seat backrest can be set to the most comfortable position. The maximum backrest tilt angle is 80°from the vertical. The mechanism consists of two pairs of upper 4 (pic. 155) and bottom 3 links. The top links are welded to the back base. The links are pivotally connected to each other by means of two eccentrics and two gear pairs of internal gearing (in fig. 155 not shown), stamped on the upper and lower links. The upper links have 30 teeth each, the lower links have 29 teeth each. Gear pairs assembled with eccentrics are non-separable, maintenance and repair are not subject. The links are pressed against each other with a spring washer. Both eccentrics of the mechanism, having square holes, are interconnected by a synchronizer 9 of a tubular section with stamped squares at the ends. Holder 13 is installed on two flats of external eccentrics (see fig. 153), made of polycarbonate, and fastened with a bolt 14 to the end of the eccentric through a gasket. A plastic handle 15 of the backrest adjustment mechanism is placed on the holder. On the side, the mechanism is closed with plastic facings 11.

Pic. 155. Mechanisms for adjusting the inclination of the backrest and reclining the backrest of the front seat:

1 - hook; 2 - hook spring; 3 - the lower link of the backrest tilt adjustment mechanism; 4 - the upper link of the backrest tilt adjustment mechanism; 5 - pull mechanism for tilting pictures; 6 - shells of rods; 7 - handle of the lever of the mechanism for reclining the back; 8 - bracket; 9 - synchronizer.

When handle 15 is turned, both eccentrics turn, providing a deflection of the upper links and, in general, the back of the front seat.

The mechanism for reclining the back of the front seat of VAZ-2108, 21081 and 21083 cars ensures the convenience of passengers getting into the back seat. In this case, the backrest leans forward, for which the lower links 3 (see fig. 155) are hinged on the base of the pillow. In the normal position, the lower links are fixed by the fingers of the pillow base with hooks 1 under the action of springs 2. The hooks are connected by rods 5 to the lever of the handle 7 of the folding mechanism. The rods are placed in polyamide shells 6, the guides of which are installed in brackets welded to the base of the backrest. The lever of the handle is covered with lining 8 (see fig. 153).

On VAZ-2109 and 21093 cars, there is no need to recline the backs. Therefore, they do not have levers with handles 7 (see fig. 155) and rods with shells 6. The remaining parts of the mechanism are in place and, if necessary, the backrest can be folded back by manually depressing the hooks 1.

On VAZ-2108 vehicles and its modifications, when the handle 7 of the tilting mechanism is moved upwards, the rods 5 retract the hooks 1 back and release the lower links 3, after which it is possible to move the seat back forward for the passage of passengers. When the seat back is returned to its normal position, the hooks lock the lower links and the back as a whole by the fingers of the base of the pillow. The normal operation of the backrest reclining mechanism is ensured by changing the lengths of the rods 5 and their reliable fastening by bending the ends of the rods on the lever and hooks of the mechanism.