Car suspension and shock absorber repair VAZ-2109

Front suspension device

Wheel suspensions are the link between the body and the wheels. Through them, the forces acting on the wheels are transmitted to the body. The elements included in the suspension...

Wheel suspensions are the link between the body and the wheels. Through them, the forces acting on the wheels are transmitted to the body. The elements included in the suspension...

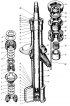

Front shock absorber device

Building 30 (pic. 70) the telescopic strut is made of a pipe, to which are welded on the outside: at the bottom there is a bracket for connecting to the steering knuckle, in the...

Building 30 (pic. 70) the telescopic strut is made of a pipe, to which are welded on the outside: at the bottom there is a bracket for connecting to the steering knuckle, in the...

Operation of the telescopic strut and shock absorber

The principle of operation of the telescopic strut, as well as the rear suspension shock absorber, is based on creating increased resistance to body swaying due to the forced flow...

The principle of operation of the telescopic strut, as well as the rear suspension shock absorber, is based on creating increased resistance to body swaying due to the forced flow...

Car wheel device

The wheels of the car are disc, with a deep one-piece rim, size 4½I-13. The front wheel hub rotates in the cavity of the steering knuckle ( see fig. 69 ) on a double-row ball...

The wheels of the car are disc, with a deep one-piece rim, size 4½I-13. The front wheel hub rotates in the cavity of the steering knuckle ( see fig. 69 ) on a double-row ball...

Vehicle tire device

The vehicles are fitted with low profile radial tires 155/80R13, 165/70R13 (165/70SR13 - imported with steel cord), 175/70R13. The tire size is applied on its sidewall and is...

The vehicles are fitted with low profile radial tires 155/80R13, 165/70R13 (165/70SR13 - imported with steel cord), 175/70R13. The tire size is applied on its sidewall and is...

Wheel alignment

Wheel alignment has a significant effect on vehicle stability, front tire wear and fuel consumption. There are the following wheel alignment angles. Collapse Camber is the tilt of...

Wheel alignment has a significant effect on vehicle stability, front tire wear and fuel consumption. There are the following wheel alignment angles. Collapse Camber is the tilt of...

Front suspension and wheel maintenance

Every 500 km, check and, if necessary, adjust the tire pressure. After the first 2000 km, and then every 15,000 km, check the condition of the front suspension parts, protective...

Every 500 km, check and, if necessary, adjust the tire pressure. After the first 2000 km, and then every 15,000 km, check the condition of the front suspension parts, protective...

Tire pressure

Check tire pressure with a pressure gauge. If there is a constant drop in tire pressure, check for air leakage through the chamber spool. In case of leakage, tighten the spool, if...

Check tire pressure with a pressure gauge. If there is a constant drop in tire pressure, check for air leakage through the chamber spool. In case of leakage, tighten the spool, if...

Mounting and dismounting tires

In order not to disturb the balance of the wheel, before disassembling it is necessary to make a mark with chalk on the tire against the chamber valve and install the tire...

In order not to disturb the balance of the wheel, before disassembling it is necessary to make a mark with chalk on the tire against the chamber valve and install the tire...

Checking the condition of the front suspension

Condition of ball joint boots determined visually and by touch on a car installed on a flyover or inspection ditch. Covers should not have ruptures, delamination of rubber,...

Condition of ball joint boots determined visually and by touch on a car installed on a flyover or inspection ditch. Covers should not have ruptures, delamination of rubber,...

Checking and adjusting wheel alignment

These complex and responsible operations are recommended to be carried out at the service station on special optical stands that ensure the accuracy of angle measurements. But...

These complex and responsible operations are recommended to be carried out at the service station on special optical stands that ensure the accuracy of angle measurements. But...

The main malfunctions of the front suspension and tires and how to eliminate them

Noise and knocks in the suspension when the car is moving Causes of the malfunction and how to fix it: suspension struts are faulty. When rocking the car, check visually and...

Noise and knocks in the suspension when the car is moving Causes of the malfunction and how to fix it: suspension struts are faulty. When rocking the car, check visually and...

Rear suspension device

Suspension of rear wheels of torsion-lever type. Its design is simple and reliable, and maintenance during the operation of the car is reduced to a minimum and consists in...

Suspension of rear wheels of torsion-lever type. Its design is simple and reliable, and maintenance during the operation of the car is reduced to a minimum and consists in...

Rear shock absorber device

Shock absorber 18 rear suspension ( see fig. 74 ) — hydraulic telescopic double-acting. For the lower lug, the shock absorber is tilted to the trailing arm bracket by a bolt with...

Shock absorber 18 rear suspension ( see fig. 74 ) — hydraulic telescopic double-acting. For the lower lug, the shock absorber is tilted to the trailing arm bracket by a bolt with...

Rear Suspension Maintenance

After the first 2000 km, and then every 15,000 km, check the condition of the suspension elements. Every 30,000 km, check the fastening of the rear suspension parts. Checking the...

After the first 2000 km, and then every 15,000 km, check the condition of the suspension elements. Every 30,000 km, check the fastening of the rear suspension parts. Checking the...

The main malfunctions of the rear suspension and how to eliminate them

Noise and knocking in the suspension when the car is moving Causes of the malfunction and how to fix it: shock absorbers are faulty. Check the condition of the shock absorbers as...

Noise and knocking in the suspension when the car is moving Causes of the malfunction and how to fix it: shock absorbers are faulty. Check the condition of the shock absorbers as...

This section is available on russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

More articles from other manuals on VAZ cars:

➠ Chassis: Car suspension VAZ-21011 (1974-1983)

➠ Chassis: Suspension and shock absorbers VAZ-2105 (1979-2010)

➠ Chassis: Suspension and wheels VAZ-2110 (1995-2007)

➠ Chassis: Wheel suspension VAZ-21213 (1994-2006)

➠ Chassis: Car suspension VAZ-21011 (1974-1983)

➠ Chassis: Suspension and shock absorbers VAZ-2105 (1979-2010)

➠ Chassis: Suspension and wheels VAZ-2110 (1995-2007)

➠ Chassis: Wheel suspension VAZ-21213 (1994-2006)

Share with friends:

- General information

- Specifications

- User manual

- Maintenance

- Car care

- Troubleshooting

- Power unit

- Engine repair

- Cooling and lubrication system

- Power and exhaust system

- Transmission

- Car gearbox

- Clutch and drive shafts

- Chassis

- Car suspension

- Steering

- Brake system

- Body

- Exterior

- Interior

- Doors and locks

- Electrical equipment

- Equipment and devices

- Lighting and signaling

- Engine electrics

- Ignition system

- General information

- Introduction to guide

- Power unit

- Engine repair

- Cooling and lubrication system

- Power and exhaust system

- Transmission

- Clutch and drive shafts

- Car gearbox

- Chassis

- Front suspension

- Rear suspension

- Steering

- Brake system

- Body

- Exterior

- Interior

- Doors and glass

- Electrical equipment

- Equipment and devices

- Engine electrics

- Ignition system

VAZbook.ru © 2017 · Mobile version · Contact with administration · Sitemap: EN BG BY UA RS HR RO PL SK HU · Site search · News and articles

VAZ-1111 · VAZ-11113 · VAZ-2101 · VAZ-21011 · VAZ-2104 · VAZ-2105 · VAZ-21051 · VAZ-2106 · VAZ-21061 · VAZ-2107 · VAZ-21099 · VAZ-2109 · VAZ-2108 · VAZ-2110 · VAZ-2112 · VAZ-2114 · VAZ-2115 · VAZ-2121 · VAZ-21213 · VAZ-21214 ·