Front wheel suspension - independent type «rocking candle» or, as it is called after the name of the inventor, MacPherson. Suspension with telescopic shock absorber struts, coil springs, lower wishbones, with braces and anti-roll bar.

The layout of the suspension and the specifics of the design of a number of its units provide for a negative rolling shoulder, in which the axis of rotation of the wheel intersects with the road outside the tire contact patch. This made it possible to apply a diagonal drive scheme for the brake mechanisms of the wheels. In the event of failure of any circuit, the braking system provides high efficiency, since the front and rear wheel brakes are always active. When braking due to the difference in braking torques on the front and rear wheels (more front than rear) the car skids, but with a negative run-in shoulder, the wheels have moments directed in the opposite direction of the skid, which ensures that the vehicle's directional stability is maintained during the operation of one circuit.

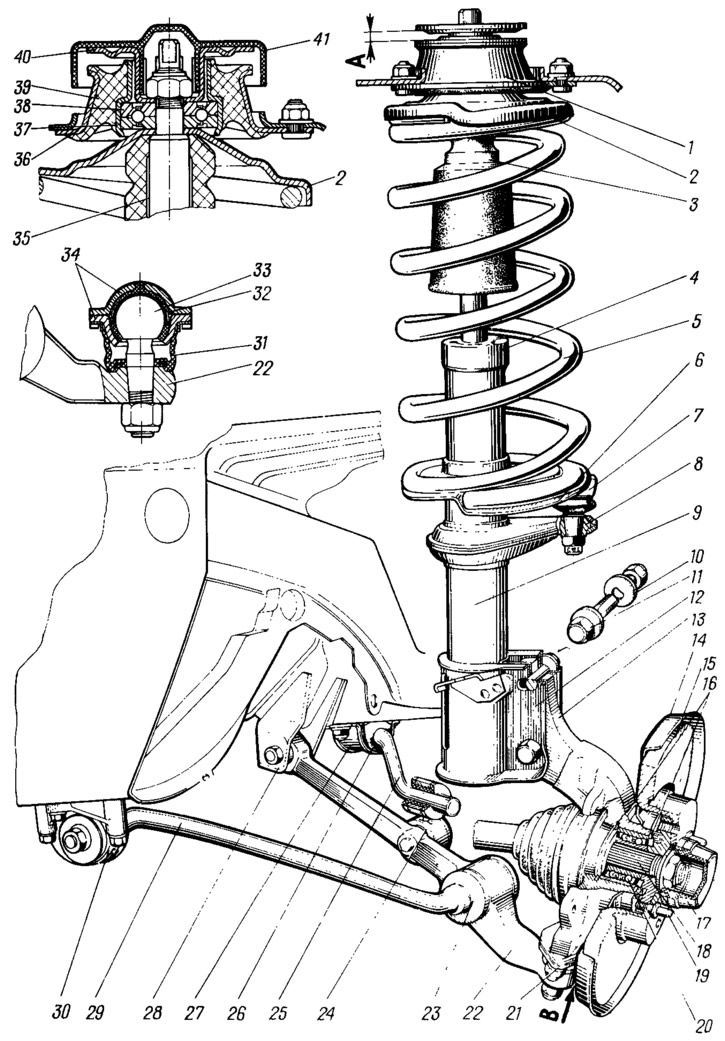

The main element of the suspension is a telescopic hydraulic strut 9 (pic. 69), which combines the functions of a guide vane and a damping element. The lower part of the telescopic rack is connected through the bracket 12 to the steering knuckle 13 with two bolts. In this case, the upper bolt 11 has an eccentric belt at the hexagonal head, and a flat at the threaded end, on which the eccentric washer 10 is put on. The eccentric belt and washer rest against the rack bracket flange, and the bolt rod passes through the cylindrical holes of the steering knuckle. This connection allows you to adjust the camber of the front wheels, since when you turn the upper bolt, the position of the steering knuckle relative to the rack changes.

Pic. 69. Front suspension assembly:

1 - upper support of the telescopic rack; 2 - upper support cup; 3 - compression stroke buffer assembly with a protective cover; 4 - compression buffer support; 5 - suspension spring; 6 - lower support cup; 7 - tie rod ball joint; 8 - rotary lever; 9 - telescopic stand; 10 - eccentric washer; 11 - adjusting bolt; 12 - rack bracket; 13 - rotary fist; 14 - protective cover; 15 - brake disc; 16 - retaining ring; 17 - wheel hub cap; 18 - splined shank of the wheel drive hinge housing; 19 - guide pin; 20 - wheel hub bearing; 21 - ball joint of the suspension arm; 22 - suspension arm; 23 - adjusting washers; 24 - anti-roll bar; 25 - stabilizer bar; 26 - rod cushion; 27 - rod mounting bracket; 28 body bracket for mounting the suspension arm; 29 - stretching the suspension arm; 30 - bracket for fastening the extension; 31 - protective cover of the ball pin; 32 - ball pin bearing; 33 - ball pin; 34 - body of the ball pin; 35 - suspension strut rod; 36 - outer casing of the upper support; 37 - inner body of the upper support; 38 - bearing of the upper support; 39 - rubber element of the upper support; 40 - travel limiter of the upper support; 41 - protective cap of the upper support.

The body 21 of the ball joint is attached to the lower part of the rotary fist with three bolts, in which the ball head of the connecting pin 33 is located. This fabric serves as a bearing for the ball pin. The pin with its conical part enters the hole of the lower suspension arm 22 and is fastened with a self-locking nut.

The protective casing 14 of the brake disc 15 is bolted to the lugs of the steering knuckle. A double-row ball bearing 20 of the closed type is installed in the cavity of the steering knuckle, on which the front wheel hub rotates.

The lower suspension arm 22 is attached to the body bracket 28 with a bolt, nut and spring washer. A rubber-metal hinge is pressed into the lever head, consisting of rubber and metal bushings.

To stabilize the position of the suspension arms, they are bursting on the one hand with stretch marks 29, on the other - with a bar 25 of the anti-roll bar. One end of the extension is connected to the lower suspension arm 22 through a rubber-metal hinge, the other to the bracket 30. This bracket is attached to the body with three bolts. Adjusting washers 23 are installed on both sides of the extension, which regulate the longitudinal angle of inclination of the axis of rotation. The rubber-metal hinge of the brace consists of two rubber and two metal bushings pressed on both sides into the hole of the lower arm 22. This hinge is clamped at the end of the brace with a self-locking nut between two support washers. The rubber-metal hinge of the brace bracket 30 consists of rubber and metal bushings, which are also clamped between two washers with a self-locking nut.

The anti-roll bar 25 is connected to the lower suspension arm by means of a short strut 24 having two heads. The lower head of the strut is connected by a bolt with a nut and a spring washer to the lower suspension arm through a rubber-metal hinge. Another strut head, into which a rubber bushing is pressed, is put on the stabilizer bar. Medium (torsion) part of the rod is attached to the side members of the body with two brackets 27 through split rubber cushions 26. The holes in the brackets 27 are oval, which makes it easier to install the rod on the car.

On the telescopic rack are installed: a helical coil spring 5, a polyurethane foam buffer 3 compression strokes, as well as an upper support 1 of the rack assembly with a bearing and mounting bolts. The spring is installed between the top 2 and bottom 6 support cups. Buffer 3 of the compression stroke, mounted on the rod, under the upper support cup, is connected to a protective casing that protects the rod from mechanical damage.

The upper support 1 of the rack consists of outer 36 and inner 37 cases, between which wear-resistant rubber 39 is installed. A thrust ball bearing 38 is pressed into the inner case of the support, after which the edges of the case are crimped in four places. Three bolts are welded to the flange part of the outer casing, which fasten the support to the mudguard rack of the body.

The upper support of the rack, together with the limiter 40, is attached to the rod with a nut. To prevent the rod from turning when it is wrapped, turnkey flats are made on it. The limiter 40 limits the stroke of the upper support. To protect the upper support from contamination, a plastic cap 41 is put on it.

The high elasticity of the top support of the telescopic pole ensures «rocking» struts during suspension travel and dampens high-frequency vibrations. The bearing built into it allows the rack to rotate when the steered wheels turn.