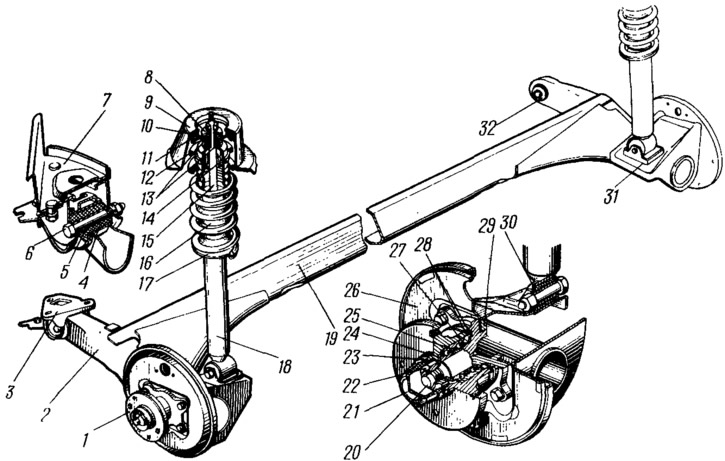

The guide element of the suspension is a beam consisting of two trailing arms 2 (pic. 74) and connector 19, welded together through amplifiers. The lever connector is significantly shifted forward from the wheel axis, it has a U-shaped section, which has high bending rigidity and low torsional rigidity. Due to the offset of the lever connector from the axle of the wheels and due to the specified section, the connector, twisting, works like a torsion bar, providing a partial independence of the movement of each wheel.

Pic. 74. Rear suspension assembly:

1 - rear wheel hub; 2 - rear suspension arm; 3 - bracket for mounting the suspension arm; 4 - rubber bushing of the lever hinge; 5 - joint spacer; 6 - a bolt of fastening of the suspension arm; 7 - body bracket; 8 - support washer for fastening the shock absorber rod; 9 - upper support of the suspension spring; 10 - spacer spring; 11 - insulating gasket of the suspension spring; 12 - rear suspension spring; 13 - shock absorber rod attachment pad; 14 - compression stroke buffer; 15 - shock absorber rod; 16 - shock absorber protective cover; 17 - lower support cup of the suspension spring; 18 - shock absorber; 19 - lever connector; 20 - wheel hub axle; 21 - hub cap; 22 - wheel hub nut; 23 - sealing ring; 24 - bearing washer; 25 - hub bearing; 26 - brake shield; 27 - retaining ring; 28 - dirt reflector; 29 - suspension arm flange; 30 - shock absorber bushing; 31 - lever bracket with an eyelet for attaching a shock absorber; 32 - rubber-metal hinge of the suspension arm.

Behind the lever connector, a space is formed in which the spare wheel and a capacious gas tank are placed. This is another advantage of the front wheel drive car layout and the adopted rear suspension design.

Trailing arms 2 are made of pipe. Brackets 31 with lugs for attaching shock absorbers, as well as flanges 29 are welded to the rear of the levers, to which axles 20 of the rear wheel hubs and shields 26 of the wheel brakes are bolted. At the front, each lever has a welded bushing, into which a rubber-metal hinge 32 is pressed, consisting of rubber bushings 4 and metal bushings 5. A bolt 6 passes through the spacer sleeve 5 of the hinge, connecting the suspension beam arm with a stamped bracket 3, which is attached to the body bracket 7 with welded bolts with nuts and washers.

The spring 12 of the suspension is made of spring steel of round section. It is mounted on the shock absorber 18. Its lower part rests on the cup 17, welded to the shock absorber reservoir, and the upper part, through the insulating rubber gasket 11, into the upper support 9, which is welded to the inner arch of the body.

The buffer 14 of the compression stroke is made of polyurethane. It is mounted on the shock absorber rod inside the suspension spring. From above, the buffer rests against the cover of the protective casing 16, and when it is turned on, it rests on the buffer support, which is put on the upper part of the shock absorber reservoir. The casing 16 protects the shock absorber rod 15 and the compression stroke buffer from mechanical damage and contamination.