- Rated power, kW - 1.3

- Current consumption at maximum power, A, not more than — 260

- The strength of the consumed current in the inhibited state, A, not more than - 500

- Current consumption at idle, without relay, A, no more than — 60

Starter type 29.3708 is a left-hand mixed-excitation DC motor with an electromagnetic two-winding traction relay. It serves to start the engine, is installed on its left side (front, when viewed in the direction of the car) and is flanged to the clutch housing with three studs.

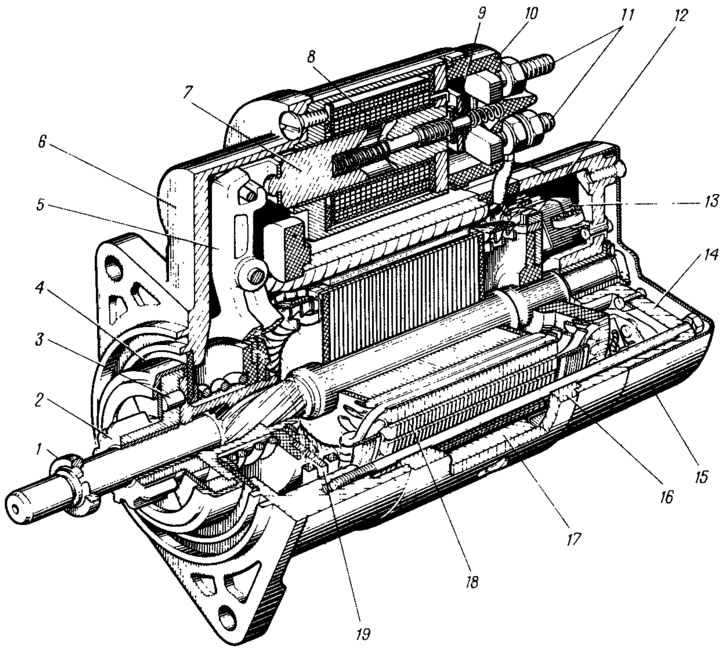

The main components of the starter housing or stator 16 (pic. 103) with excitation windings, armature 18 with overrunning clutch 4, cover 6 on the drive side with lever 5, cover 14 on the collector side with brush holders and traction relay. Covers 6, 14 and the body are connected by two tie bolts.

Pic. 103. Starter:

1 - restrictive ring; 2 - drive gear; 3 - overrunning clutch roller; 4 - overrunning clutch; 5 - drive lever; 6 - cover on the drive side; 7 - relay armature; 8 - relay winding; 9 - contact plate; 10 - relay cover; 11 - contact bolts; 12 - collector; 13 - brush; 14 - cover from the side of the collector; 15 - casing; 16 - body; 17 - stator pole; 18 - anchor; 19 - driving ring.

The body is made of mild steel strip rolled into a cylinder and welded at the joint. Inside the case, four steel poles 17 are fixed with screws, on which the winding coils are put on. The housing, together with the coils and poles, forms the stator. Three stator coils (serial) connected to the armature winding in series, and one (shung) - in parallel. Therefore, the excitation of the starter is mixed. It provides a relatively low idle speed of the armature, which reduces wear on the bearing bushings, facilitates the operation of the overrunning clutch and prevents armature runaway.

The main current consumed by the starter flows through the serial coils and the armature winding. Therefore, they are wound with copper tape with a large cross section. A relatively small current flows through the shunt coil, which depends mainly on the voltage of the battery. Therefore, the shunt coil is wound with copper wire in enamel insulation. Coils are braided with cotton tape and impregnated with varnish.

Anchor 18 consists of a shaft on which a core made of electrical steel plates is pressed, and a collector 12. A winding made of copper tape is placed in the grooves of the core. The ends of the winding are soldered to the collector plates. The armature shaft rotates in two ceramic-metal bushings impregnated with oil. The rear bushing is pressed into cover 14, and the front bushing is located in the clutch housing. The front end of the armature shaft enters this bushing when the starter is attached to the clutch housing.

The starter uses an end-type collector. It is a plastic disk in which the copper contact plates of the collector are filled. The use of an end collector made it possible to reduce the length of the starter and its weight. In addition, such a collector contributes to a more stable and long-term operation of the brush contact.

At the front end of the armature shaft, a starter drive is installed, consisting of a roller overrunning clutch and gear 2. The purpose of the overrunning clutch is to transmit torque from the starter armature shaft to the flywheel crown through gear 2 when starting the engine, and after starting, while working in overtaking mode, to prevent transmission of torque from the flywheel to the armature. Otherwise, the armature winding may come out of the core slots due to «spacing» - excessively high frequency of rotation of the armature by the flywheel of a running engine.

The overrunning clutch consists of an outer ring with rollers 3 and an inner drive united with gear 2. The outer ring has three grooves of variable depth. In the deeper part of the groove, the rollers can rotate freely, in the shallower part they are wedged between the outer and inner rings. The rollers are pressed into the less deep part of the groove by springs.

Covers 6 and 14 are cast from aluminum alloy. Four brush holders with copper-graphite brushes are riveted to cover 14 on the inside. Two brush holders with positive brushes are isolated from the cover with textolite washers and bushings. The other two brush holders with negative brushes are riveted directly to the cover, i.e. connected to «weight».

A plastic lever 5 is installed in the cover 6 on the axle, which transmits the traction force from the relay to the starter drive. The grooves of the lever include the ears of the driving ring 19, mounted on a plastic centering disk. This disc, together with the restrictor ring and the buffer spring, is fixed with a retaining ring on the hub riveted to the outer ring of the overrunning clutch 4.

The traction relay, attached with three screws to cover 6, serves to engage the drive gear with the flywheel ring and to close the power circuit of the armature and stator windings. The relay has two windings: retracting and holding, wound in one direction. The beginning of the windings are soldered to the plug «50» on the relay cover. The end of the holding winding is welded to the relay flange (i.e. connected to «weight»), and the end of the retracting winding is connected to the lower contact bolt of the relay.

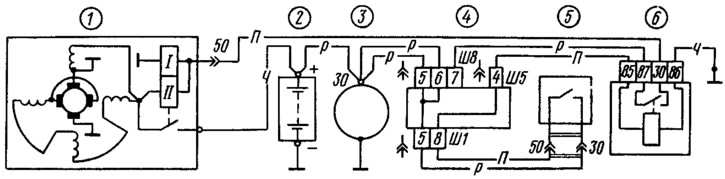

On fig. 104 shows the starter switching circuit using auxiliary relay 6 type 113.3747-10, installed in the engine compartment on the bulkhead. At the beginning of the production of VAZ-2108 cars, this relay was not installed, and the voltage from the ignition switch was applied directly to the starter traction relay.

Pic. 104. Starter connection diagram:

1 - starter; 2 - battery; 3 - generator; 4 - mounting block; 5 - ignition switch; 6 - starter relay.