Open large image in new tab »

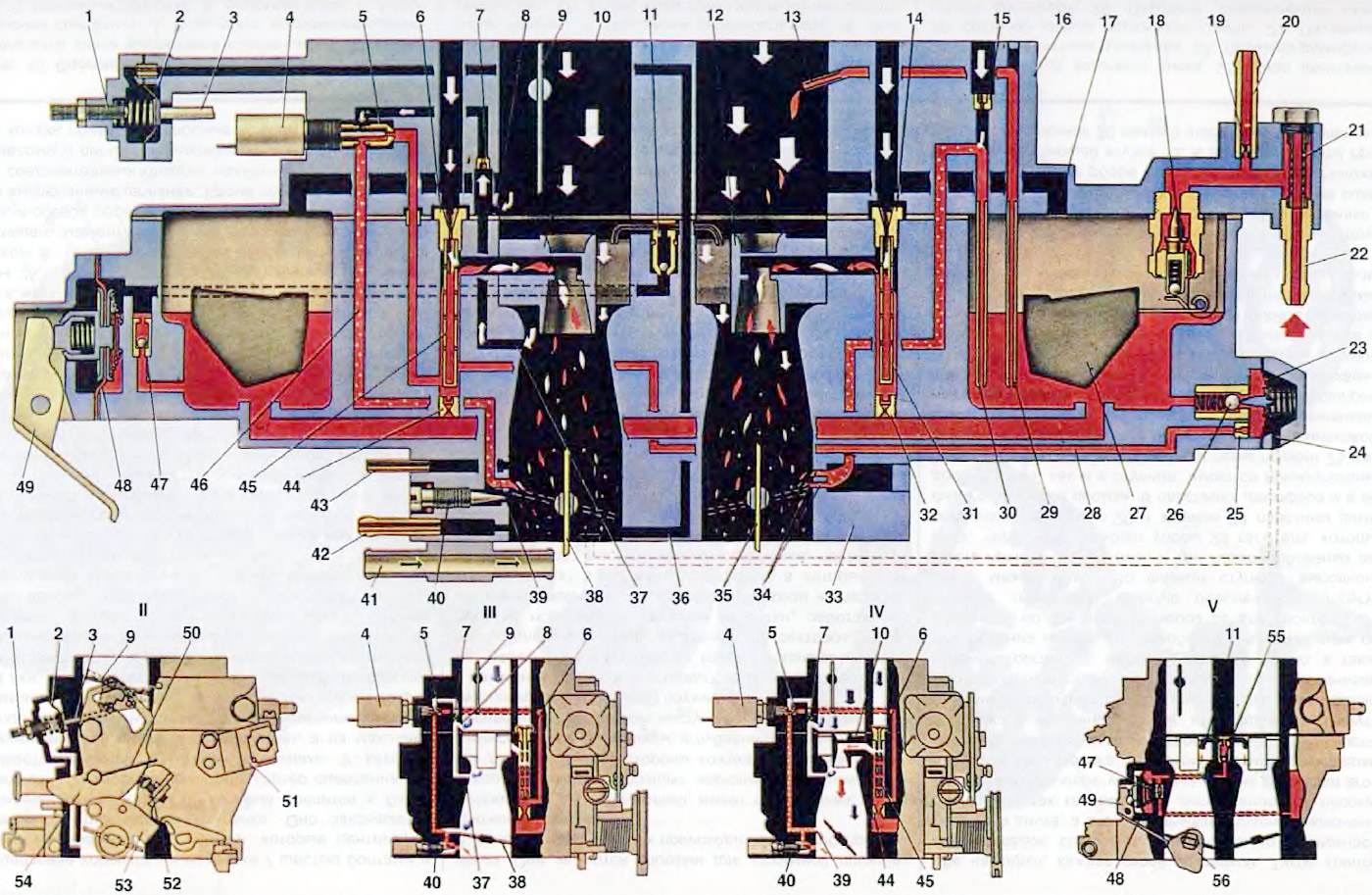

Pic. 15. Scheme of the carburetor: 1. Trigger adjustment screw; 2. Diaphragm of the starting device; 3. Trigger rod; 4. Shut-off solenoid valve; 5. Fuel jet idling; 6 Main air jet of the first chamber; 7. Air jet idling; 8. Idle flow channel; 9. Air damper; 10. Atomizer of the main dosing system of the first chamber; 11. Accelerator pump nozzles. 12. Atomizer of the main dosing system of the second chamber: 13. Econostat injection tube; 14. The main air jet of the second chamber; 15. Air jet of the transitional system of the second chamber. 16. Carburetor cover; 17 Float chamber balancing hole; 18. Needle valve; 19. Calibrated hole for bypassing fuel into the tank; 20. Pipe for draining fuel into the tank; 21. Fuel filter; 22. Fuel supply pipe; 23. Economizer diaphragm power modes; 24. Air channel of the economizer of power modes, 25. Fuel jet of the economizer of power modes; 26. Ball valve economizer power modes; 27. Float; 28. Fuel channel economizer power modes; 29. Econostat fuel jet with tube; 30. Fuel jet of the transition system of the second chamber with a tube; 31. Emulsion tube of the second chamber; 32. The main fuel jet of the second chamber; 33. Carburetor body; 34. Outlets of the transition system of the second chamber; 35. Throttle valve of the second chamber; 36. Air channel of the starting device; 37. Opening of the air channel of idling; 38. Throttle valve of the first chamber; 39. The slot of the transition system of the first chamber; 40. Adjusting screw for the quality of the idle mixture; 41. Carburetor heating block; 42. Pipe for suction of crankcase gases; 43. Pipe for supplying vacuum to the vacuum regulator of the ignition distributor; 44. The main fuel jet of the first chamber; 45. Emulsion tube of the first chamber; 46 Idle emulsion channel; 47. Accelerator pump ball valve; 48. Accelerator pump diaphragm; 49. Accelerator pump drive lever; 50 Thrust of the handle of the air damper drive; 51. Arm of fastening of a cover of draft of a drive of the air damper; 52. Adjusting screw for slightly opening the throttle valve of the first chamber; 53. Throttle actuator lever; 54. Choke control lever; 55. Accelerator pump fuel supply ball valve; 56. Accelerator pump drive cam; I. Carburetor operation at maximum engine power; II. The operation of the starting device; III. Carburetor operation at idle speed of the engine; IV. Carburetor operation during the transition to medium engine loads; V. Operation of the accelerating pump.

The main metering system is fed from the float chamber, into which fuel enters through the needle valve 18. Through the main fuel jets 44 and 32, the fuel enters the emulsion wells. With sufficient vacuum in the sprayers of the main metering systems, the fuel is mixed in emulsion wells with air entering through the main air jets 6 and 14, and is sucked into the diffusers of the mixing chambers in the form of an emulsion. Only the main dosing system of the first chamber operates in the throttling mode. The second chamber begins to open and operate when the throttle valve of the first chamber is more than two-thirds open.

The idle system provides the necessary composition of the combustible mixture at idle. In this case, the throttle valves 38 and 35 are closed. Fuel from the emulsion well of the main metering system rises through the fuel channel, passes through the fuel jet 5, mixes with air from the air jet 7 and the flow channel, and then enters under the mixture quality screw 40 and into the throttle space.

The transition system of the first chamber provides a smooth transition of the engine from idling to throttling modes. At the moment of opening the throttle valve of the first chamber, the gap 39 of the transition system falls under vacuum. An emulsion will also flow from it, providing a smooth transition.

The transitional system of the second chamber ensures a smooth transition of the engine operation at the moment the throttle valve of the second chamber begins to open. At this point, holes 34 are under vacuum; fuel from the float chamber through the jet 30 rises up the tube, air is mixed from the air jet 15, and the emulsion enters through the emulsion channel through the outlet openings under the throttle valve.

The econostat enriches the combustible mixture at fully open throttle valves at speeds close to maximum. With open throttle valves, the vacuum in the mixing chambers and the tube 13 of the econostat increases significantly. Fuel from the float chamber enters through the econostat jet 29 and the injection tube 13 into the second mixing chamber.

The power economizer prevents changes in the degree of mixture enrichment due to vacuum pulsation under the throttle valve, especially when the crankshaft speed is reduced, when the pulsation increases and the vacuum decreases. The economizer ball valve 26 is closed as long as diaphragm 23 is held by vacuum under the throttle. With a significant opening of the throttle valve 38, the vacuum decreases slightly, and the diaphragm spring opens the valve. The fuel passes through the valve, the economizer jet 25, is added to the fuel passing through the main fuel jet 44, and equalizes the enrichment of the mixture.

Accelerator pump diaphragm type driven by a cam on the axis of the throttle valve of the first chamber. With a sharp opening of the throttle valve, the cam presses the lever 49 and through the spring in the pusher acts on the diaphragm 48, overcoming the resistance of the return spring. The diaphragm supplies fuel through the supply ball valve and injects it through the nozzles 11 into the mixing chambers. During the reverse stroke of the diaphragm, under the action of a return spring, fuel is sucked from the float chamber through the check ball valve 47 into the working cavity of the accelerator pump.

The starting device ensures the preparation of a rich combustible mixture when starting a cold engine. When the air damper control lever 54 is turned by the rod 50 counterclockwise, the throttle valve 38 of the first chamber is slightly opened by the outer edge of the adjusting screw 52. At the same time, the expanding groove of the lever 54 releases the pin of the air damper lever, and it will be held completely closed due to the return spring. The axis of the air damper is displaced, therefore, after starting the engine, the air damper can be slightly opened by the air flow, stretching the spring, which ensures that the mixture is leaner.

The vacuum from the throttle space acts on the diaphragm 2 and can slightly open the air damper by the stem 3. The adjusting screw 1 allows you to adjust the amount of opening of the damper.

The overrun economizer disables the overrun idle system (during engine braking, when driving downhill, when shifting gears), excluding emissions of carbon monoxide into the atmosphere.

The economizer includes a limit switch mounted on an adjusting screw 18 (see fig. 12) idle mixture quantity, solenoid shut-off valve 10, electronic control unit and electrical wires for connecting devices.

At forced idle, if the speed begins to increase, then the voltage to the winding of the electromagnetic shut-off valve 4 (see fig. 13) is supplied until the electronic control unit, until the crankshaft speed exceeds 2100 rpm, although the limit switch is closed to "mass". At higher engine speeds, the ECM cuts off power to the solenoid shut-off valve, cutting off fuel supply to the idle system.

When the engine crankshaft speed decreases at forced idle to 1900 rpm, the electronic control unit again starts supplying power to the valve winding, and it opens the fuel supply through the idle jet, the engine gradually enters the idle mode, although the limit switch is closed on "mass".