Open large image in new tab »

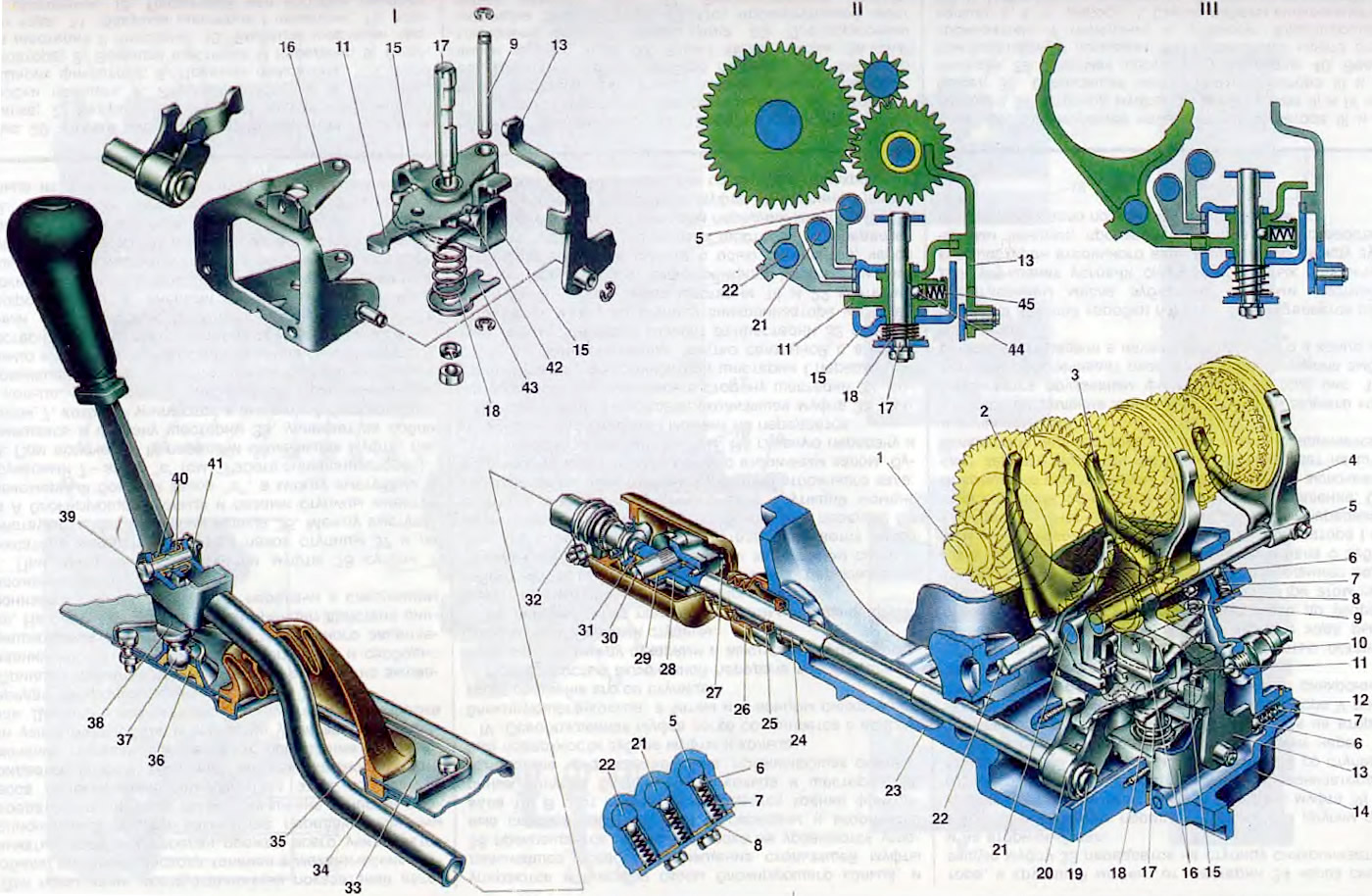

Pic. 19. Gearshift drive: 1. Secondary shaft; 2. Switching fork of I and II gears; 3. Switching fork III and IV gears; 4. Fork of inclusion of V transfer; 5. The rod of the fork of inclusion of the V transfer; 6. Retainer ball; 7. Detent spring; 8 Gear shift rod retainer cover; 9. The guide axis of the locking bracket; 10. Reversing light switch; 11. Three-arm gear selection lever; 12. Stopper of a clamp of a plug of inclusion of a backing; 13. Reverse fork; 14. Gearbox housing; 15. Locking bracket; 16. Housing gear selection mechanism; 17. Axis of gear selection lever; 18. Spring gear selection lever; 19. Gear selection rod; 20. The lever of a rod of a choice of transfers; 21. Stem fork switching III and IV gears; 22. The rod of the shift fork of I and II gears; 23. Clutch housing, 24. Sleeve; 25. Seal of the gear selection rod; 26. Protective cover of the hinge; 27. Tapered hinge screw; 28. Gearshift drive rod hinge housing; 29. Hinge bushing; 30. Hinge axis; 31. Hinge tip; 32. A collar of draft of a drive of a gear change; 33 Gear lever housing; 34. Gearshift drive rod; 35. Protective cover of the gearshift drive rod; 36. Ball bearing gear lever; 37. Spherical finger of the gear lever; 38. Gear lever; 39. The axis of the gear lever; 40. Sleeve axis of the gear lever; 41. Locking bracket; 42. Gear selector lock; 43. Thrust washer gear selection lever; 44 Gear selector lock ball; 45. Detent spring; I. Details of gear selection mechanism; II. Reverse selection; III. Front code selection.

The gear shift drive consists of a lever 38 with a ball pin 37, a ball bearing 36, a rod 34, a hinge, a gear selection rod 19 and gear selection and shift mechanisms.

The gear lever 38 is connected to the rod 34 by the axle 39, which passes through the plastic bushings 40 and is locked by the bracket 41. The ball head of the lever is located in the spherical seat of the ball bearing 36, made of plastic. It has four radial slots to facilitate the insertion of the lever into the support. The support is located in the nest of the body 33 of the lever, which is bolted to the floor of the body. Rod 34 is tubular, with a welded lug for connection to the gear lever. At the other end of the rod, a slot is made for fastening the hinge with a clamp 32. The place where the rod exits under the floor of the body is sealed with a cover 35. The hinge does not allow the transfer of forces to the drive from oscillation and movement of the power unit. It consists of a body 28 and a tip 31, pivotally connected to each other by an axis 30. The hinge body is mounted on the rod 19 with a conical screw 27, and the tip of the hinge is attached to the rod 34 with a clamp 32. Small slots are cut on the tip for strength. The hinge is closed with a protective cover 26, which is fastened on one side with a flange on the tip of the hinge, and on the other hand, on the stuffing box body 25. To prevent damage to the cover when moving the rod 19, corrugations are made on it. The gear selection rod 19 is installed in the holes of the clutch housing, and its outer end rests on the sleeve 24 and is sealed with an oil seal 25 at the outlet. The gear selection lever 20 is attached to the inner end of the rod with a conical screw. It consists of a two-arm lever and a plate having a single hub. Between the short arm and the plate there is one arm of the three-arm lever 11 of the gear selection mechanism. Therefore, when the axial movement of the rod 19 is the rotation of the lever 11 on its axis. The long arm of the lever 20 of the gear selection rod also interacts with the lever 11, but moves it along the axis.

The gear selection mechanism is made as a separate unit, fixed with three bolts on the clutch housing. It consists of a housing 16, a three-arm gear selection lever 11, an axis 17 of the gear selection lever, two locking brackets 15, an axis 9 of the locking brackets, a reverse fork 13, a spring 18, a thrust washer 43. Two axles are fixed on the housing 16 of the gear selection mechanism 17 and 9: one with a nut, the other with circlips. A spring 18 is installed on the axle 17, a three-arm lever 11 and locking brackets 15, which have a single hub. Axis 9 passes through the holes of the hub, fixing them from turning. A retainer ball 44 is mounted in the hub of the three-arm lever. One arm of the three-arm lever serves to engage forward gears, the other to engage reverse gear, and the lever 20 of the gear selection rod acts on the third arm.

Locking brackets block the forward shift fork rods when the reverse gear is engaged, and when the forward gears are engaged, the reverse fork and other forward gear shafts. In the neutral position of the gear lever, the spring 18 moves the lever 11 and the locking brackets 15 on the axles until the ball 44 of the latch stops against the step of the axle 17. In this position, the brackets lock the reverse fork 13 with one end, entering its groove, and the other end locks the fork 1st and 2nd gears, as well as the 5th gear stem: the forward gear selection lever is set to the 3rd and 4th gears, i.e. 3rd or 4th gear is selected. Longitudinal movement of the gear lever engages one of the indicated gears. When the gear lever is moved transversely in the direction of the reverse gear, the rod 19 rotates on its supports and the long arm of the lever 20 moves the lever 11 and the locking brackets 15 on the axles. In this case, the spring 18 is compressed, one end of the bracket comes out of the groove of the reverse fork and instead of it the shoulder of the lever 11 enters the groove, and instead of the lever 11, the other end of the bracket enters the groove of the III and IV gear rod. Thus, the rods with the forward gear forks will be blocked and it will be possible to engage only the reverse gear.

The shift mechanism transmits the force from the shift lever to the synchromesh clutches and the reverse idler gear. It consists of rods 5, 21, 22 and forks 2, 3, 4, as well as ball clamps. The rods are located in the sockets of the gearbox and are fixed in the neutral and on positions by ball clamps 6, which are located in three channels and are closed by a common cover. Forks 2, 3 and 4 are bolted to the rods, which cover the synchronizer couplings. The shift fork of I and II gears has a groove into which one shoulder enters when choosing gears (forward gear lever) three-arm gear selector. For rods of III and IV gears, the grooves for the selector lever are made in the bosses of the rods themselves. The fork 13 of the reverse gear is located on the axis of the housing of the gear selection mechanism and is locked on it with a lock washer. The reverse fork is fixed with a separate latch, into the socket of which a plug 12 is screwed. When the reverse gear is turned on, the fork 13 acts on the stem of the reverse light switch 10, which is screwed into the gearbox housing. This closes the reversing light circuit.

To ensure a clear engagement of gears, the drive is adjusted, for which: loosen the coupling bolt of the clamp 32 and set the rod 19 to the neutral position. With the decorative cover raised, lever 38 is installed so that its lower part is perpendicular to the floor of the body, and the handle is from the right seat at a distance of 1/3 of the distance between the seats and tighten the clamp nut 32.