Open large image in new tab »

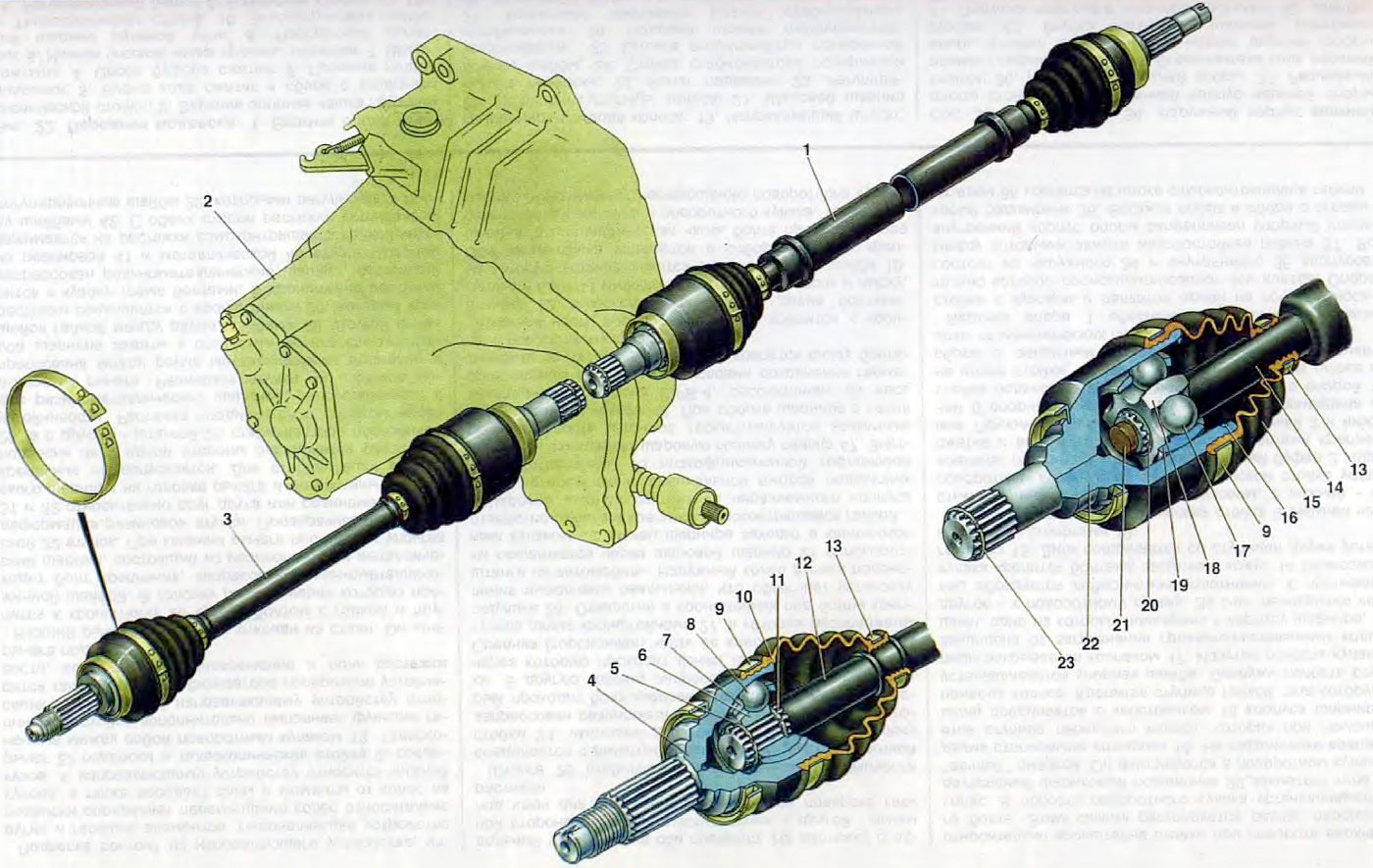

Pic. 21. Front wheel drive: 1. Right front wheel drive; 2. Gear box; 3 Left front wheel drive; 4. External hinge housing; 5. Retaining ring of the hinge cage; 6, 18. Hinge holder; 7, 19. Hinge separator; 8, 17 ball joint; 9. Outer collar of the cover; 10, 15. Protective cover of the hinge; 11. Thrust ring; 12, 14. Left wheel drive shaft; 13. Internal collar of a cover; 16. Internal hinge retainer; 20. Retaining ring of the inner joint holder; 21. Shaft buffer; 22. Internal hinge housing; 23. Retaining ring side gear.

A front-wheel drive car is characterized primarily by the fact that the front steered wheels are simultaneously driving. To turn the drive wheels on the shafts (axle shafts) drive are ball joints, which must allow the wheels to turn without changing the speed of their rotation. This condition is satisfied by cardans of equal angular velocities (synchronous ball joints). Under these conditions, a conventional cardan joint quickly fails, since when its driving and driven links deviate, rotation is transmitted to the driven link unevenly in angular velocity. This causes an overload of the drive shafts and rapid wear of the cardan joint.

In modern front-wheel drive vehicles, axle shafts with two synchronous ball joints are used to drive the front wheels: the drive wheel has a rigid type (with angular degree of freedom), and for the power unit - universal type (with angular and axial degrees of freedom).

The front wheel drive used on the car is compact and reliable. Its durability with proper operation of the car is high. This is ensured by the perfection of the design of the hinges, the selection of improved materials, the accuracy of manufacturing parts, good tightness of the hinges and the use of special lubricants.

The drives of the right 1 and left 3 wheels have the same design and differ in shafts, which are solid for the left wheel drive, and tubular for the right one, and also in length. The latter is explained by the shift of the gearbox to the left side of the vehicle axis.

The drive of each wheel consists of two cardan joints of equal angular velocities and a shaft. The outer hinge, connected to the wheel hub, consists of a housing 13, a separator 6, an inner cage 4 and six balls. In the body of the hinge and in the cage there are radial raceways, the curvature of which has a meridian direction. In these paths there are balls that connect the body 4 and the inner cage 6. The balls are placed in the windows of the separator 7 and are held in the same plane. As a result, the inner race and the hinge body are centered. The working angle of rotation of the outer hinge is up to 42°.

The inner cage is mounted on the splines of the shaft 8 until it stops in the ring 11. The cage is held on the splines of the shaft by a retaining ring 5. The separator has a spherical surface and windows for balls. It ensures synchronous rotation of the shafts connected by the hinge due to the installation of balls in the sectorless plane of the angle of the intersecting axes of the hinge links, that is, it acts as a divider. As a result, regardless of the angle of rotation of the hinge, the balls are always kept in the plane of constant speed. At the same time, torque is transmitted through the separator.

To seal the hinge cavity, a corrugated rubber boot 10 is used, which is fastened to the hinge body and to the wheel drive shaft 12 with clamps 9 and 13. The tightness of the boot seats is ensured by annular grooves on the hinge housing, into which the boot is pressed when the clamp is tightened. On the other hand, the grooves are made in the case itself, they create a labyrinth seal. Axial fixation of the cover on the shaft is achieved by thrust collars on the drive shaft. Tightening collars are made of steel tape, on which three nests and one fixing tooth are stamped. Two nests are used to tighten the clamp with a special device, the third one includes a fixing tooth. The front wheel hub is mounted on the splined tip of the hinge housing. It is secured with a self-locking nut.

The inner joint is connected to the side gear of the differential. It has minor design differences compared to the external hinge. This is primarily due to the fact that the tracks in the hinge body and in the cage are made straight, not radial, which allows the hinge parts to move in the longitudinal direction. This is necessary to compensate for movements caused by oscillations of the front suspension and power unit. The longitudinal movement of the cage in the hinge body is limited on one side by a wire retainer 16, on the other hand, by a plastic buffer 18. The retainer is installed in the groove of the hinge body, and the buffer is installed in the end of the wheel drive shaft. The shank of the hinge housing is connected by splines to the side gear of the differential. The side gear is held on the splines of the shaft by a retaining ring 23.

Protection of hinge parts from moisture and dirt is carried out in the same way as for the outer hinge.

When assembling the cardan joints, a special lubricant SHRUS-4 is laid in them. When operating the car, the lubricant is not replaced if the covers ensure the tightness of the hinges.

Front wheel drives operate under the most severe and adverse conditions, as they are located in the area of the greatest exposure to moisture and dirt and transmit torque to the wheels at constantly changing angles and loads. High precision manufacturing of hinge parts, the use of high-quality materials and lubricants ensure reliable operation of the unit even under these conditions, but only while maintaining the tightness of the hinges. Therefore, it is necessary to periodically check the condition of protective covers and clamps in order to timely detect cracks, deformations or traces of rubbing against the road surface on them and take measures to replace them. This prevents premature wear of the hinges.