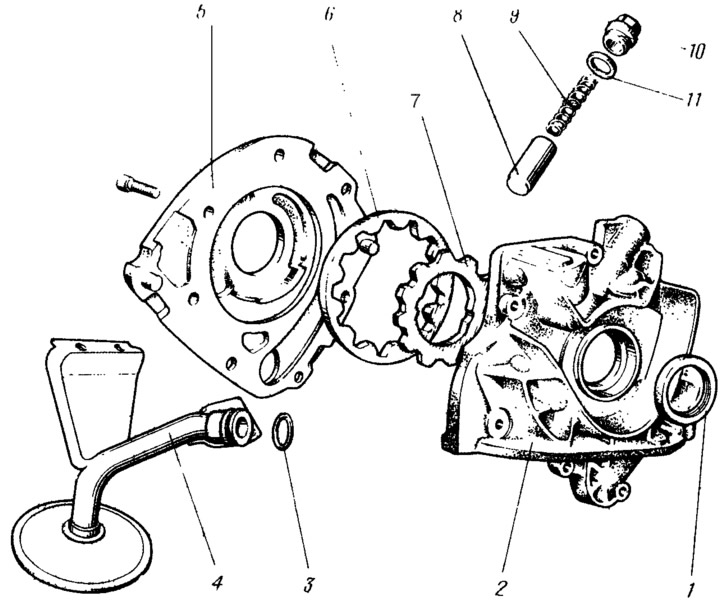

Pic. 37. Oil pump parts:

1 - front crankshaft oil seal; 2 - pump cover; 3 - rubber sealing ring; 4 - oil receiver; 5 - pump casing; 6 - driven gear; 7 - drive gear; 8 - pressure reducing valve; 9 - pressure reducing valve spring; 10 - cork. 11 - sealing ring.

The pump consists of a cover 2, a housing 5 with suction and discharge cavities, an oil receiver 4 and a pressure reducing valve 8. The driving 7 and driven 6 gears are placed in the housing. To ensure the necessary clearances between the gears and the housing when the temperature changes, the housing is cast from cast iron, and the gears are made of cermet with linear expansion coefficients close to each other.

In the housing, the suction cavity is separated from the discharge cavity by a sickle-shaped protrusion. The cover 2 of the pump is made of aluminum alloy. The pump body is connected to the cover with screws and sealed with liquid sealant type Loctite No. 329 or activator No. 738 (liquid gasket).

The drive gear of the pump is mounted on two flats of the crankshaft. The oil that has leaked to the stuffing box 1 is discharged into the engine crankcase through the grooves on the pinion flats. Trochoidal gear pump gears, which achieve a reduction in mechanical losses on the drive and an increase in the efficiency of the pump compared to involute gears.

Pump performance at 6000±120 rpm drive gear and back pressure 5 kgf/cm2 should be at least 34 l / min.

The oil receiver 4 is attached with one bolt to the pump cover and with two bolts to the cover of the second main bearing. The oil receiver tube in the pump cover is sealed with a rubber ring B. From the bottom, the oil receiver has a cup with a mesh and a spherical damper with a hole in the center, which reduces the possibility of air leakage when the engine is tilted.

The discharge channel in the pump cover is connected by a channel to the oil filter. The pressure reducing valve 8 of the piston type is located in the cover. The required valve actuation pressure is provided by spring 9. When the valve is actuated, oil is bypassed into the suction cavity of the pump.

When the engine is running, the gears of the oil pump suck oil from the crankcase through the oil receiver and the suction cavity. The cavities of the teeth of the pump gear distill the oil into the discharge cavity and supply it under pressure through the oil filter to lubricate the rubbing parts. After the engine is stopped, part of the oil remains in the discharge cavity of the pump and will allow the pump to quickly start working after the next engine start.