Trigger Adjustment

When turning lever 4 (see fig. 50) control of the air damper 5 fully counterclockwise, the air damper must be completely closed under the action of the spring 7. If the damper is not closed, eliminate the cause of jamming. With the air damper fully closed, manually press the trigger rod 3 as far as it will go. In this case, the air damper 5 should open by the value V (see table. 2). If necessary, adjust this gap with the adjusting screw 2.

Throttle valve 12 of the first chamber with a fully closed air damper should be ajar by the value C (see table. 2). It is necessary to adjust this gap with screw 10.

Carburetor Drive Adjustment

With pedal fully depressed 1 (see fig. 51) throttle control, the throttle valve of the first chamber must be fully open and sector 15 must not have an additional stroke. When the pedal is released, the throttle should be fully closed. If this is not the case, adjust the position of the pedal and throttle with adjusting nuts 13 on the front end of the drive cable. The drive should run without jamming.

In the air damper drive, fix the shell 10 of the rod 14 so that the shell protrudes 40 mm beyond the carburetor bracket, as shown in the figure. Fix the rod 14 on the lever 16 of the air damper control so that when the handle 8 is extended, the damper is completely closed, and when the handle is recessed, it is completely open.

Engine idle adjustment

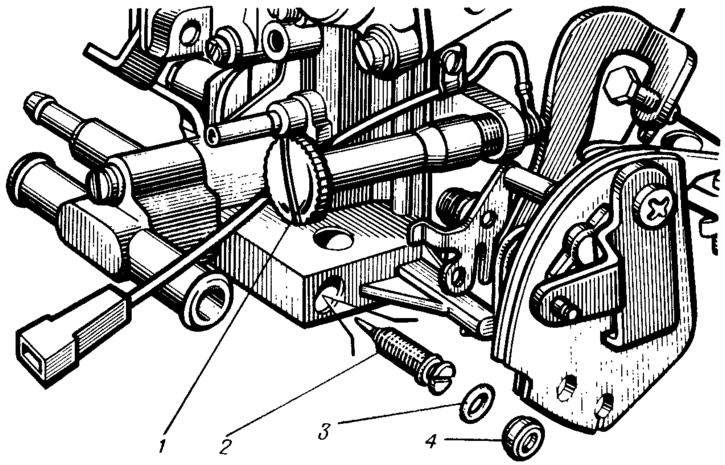

The idle speed control system has an adjusting screw 2 (pic. 55) quality (composition) mixture and adjusting screw 1 of the mixture amount. To access the adjusting screw 2, it is necessary to break the plug 4 with a corkscrew type tool.

Pic. 55. Screws for adjusting the idle system:

1 - adjusting screw for the amount of the mixture; 2 - quality adjusting screw (composition) mixtures; 3 - sealing ring: 4 - plug of the adjusting screw.

Idle speed adjustment should be done with the engine warm (coolant temperature 90...95°С) with adjusted gaps in the gas distribution mechanism, with a correctly set advance angle and with a fully open air damper.

Using the adjusting screw 1 of the mixture amount, set the engine crankshaft rotation speed within 750... 800 rpm using the stand tachometer. Then adjusting screw 2 quality (composition) mixture to achieve a concentration of carbon monoxide (SO) (reduced to 20°C and 760 mm Hg. Art.) in exhaust gases within 0.5... 1.2% at a given position of screw 1.

Using screw 1, restore the crankshaft speed to 750... 800 rpm. If necessary, use the adjusting screw 2 to restore the CO concentration to 0.5... 1.2%.

At the end of the adjustment, sharply press the throttle pedal and release it, the engine should increase the crankshaft speed without interruption, and when it decreases, it should not stall. If the engine is stopped with screw 1, increase the crankshaft speed within 750... 800 rpm.

Install a new plastic plug 4 into the hole for adjusting screw 2 of the mixture quality.

Checking the forced idle economizer

Checking the forced idle economizer consists in checking the operation of the carburetor solenoid shut-off valve (see chapter «Carburetor Solenoid Valve Control System»; chapter «electrical equipment») .

Checking the operation of the locking mechanism of the second chamber of the carburetor

Turn the choke control lever counterclockwise until the choke is fully closed. Then rotate sector 19 (see fig. 53) throttle control until the first chamber damper is fully opened, while the second chamber damper must remain in the closed position.

Turn the choke control lever clockwise, and the throttle control sector until they are fully open. If the second chamber throttle does not open, repair the problem. The reason may be jamming of the second chamber blocking lever 21 or disconnection of the spring 22 of the blocking lever.