Remove cover 6 (see fig. 42) air filter and filter element. Unscrew the nuts securing the filter housing 4 to the carburetor. Remove the housing assembly with the thermostat 3, disconnect the corrugated hose 2 and the crankcase ventilation exhaust hose, after loosening the fastening clamps.

Removing the carburetor

Disconnect from sector 15 (see fig. 51) throttle actuator cable and return spring 17, and also disconnect the rod 14 from the carburetor, the shell 10 of the air damper actuator rod. Unscrew the fastening screw and remove the carburetor heating block. Disconnect from the carburetor the electrical wires of the limit switch and the electromagnetic shut-off valve, as well as the vacuum extraction and crankcase ventilation hoses. Unscrew the carburetor mounting nuts, remove the carburetor, heat shield, heat-insulating spacer and close the outlet of the inlet pipe with a plug.

Dismantling the carburetor

Unscrew the screws securing the carburetor cover and carefully remove it so as not to damage the gasket, float, econostat tubes and the transition system of the second chamber.

Dismantle the carburetor cover, for which, carefully push out axle 1 with a mandrel (pic. 52) float 3 from the racks and, without damaging the float reeds, remove it. Remove the cover gasket 4, unscrew the needle valve seat 2, unscrew the fuel supply pipe 11 and remove the fuel filter 12. Unscrew the idle fuel jet housing with the electromagnetic shut-off valve 10 and remove the jet 9. Unscrew the axle 19, remove the ball 17 with the spring, remove the lever 18 choke control, disconnect the choke lever spring. If necessary, unscrew the screws securing the air damper, remove the damper 15 and shaft 16.

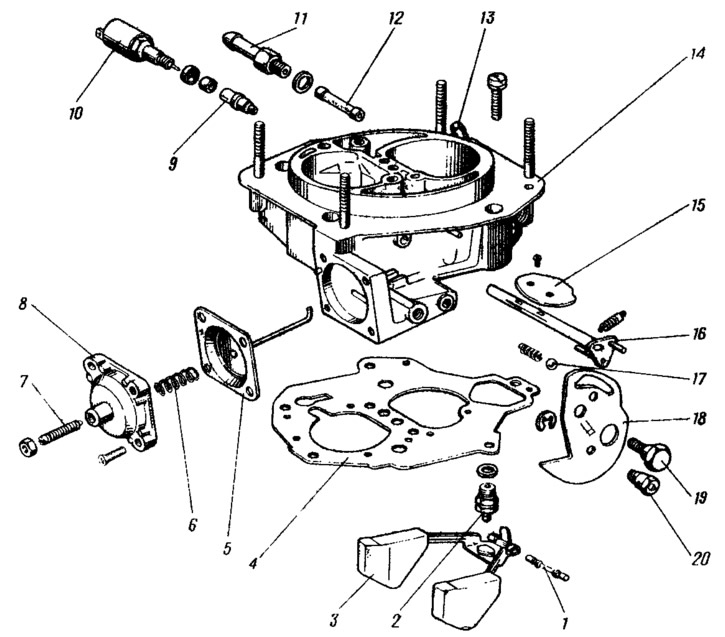

Pic. 52. Carburetor cap details:

1 - float axis; 2 - needle valve; 3 - float; 4 - gasket; 5 - diaphragm of the starting device with a rod, 6 - spring; 7 - adjusting screw; 8 - starter cover; 9 - idle fuel jet; 10 - electromagnetic clans; 11 - fuel supply pipe to the carburetor; 12 - fuel filter; 13 - fuel drain pipe; 14 - carburetor cover; 15 - air damper; 16 - axis of the air damper with a lever; 17 - ball for fixing the air damper control lever; 18 - air damper control lever; 19 - lever axis; 20 - bushing for fastening the air damper drive rod.

Disassemble the diaphragm starter by removing the cover 8 assembly with the adjusting screw 7. Remove the spring 6 and the diaphragm 5 with the stem.

Disassemble the carburetor body (pic. 53), for which remove the cover 3 of the accelerator pump with lever 2 and diaphragm 1. Remove the nozzles 10 of the accelerating pump and the nozzles 11 of the first and second chambers of the main dosing systems. Take out the accelerator pump nozzles only by the housing. Unscrew the nut of the throttle valve axis of the first chamber, remove the cam 4 of the accelerator pump drive and the washer. Unscrew the fastening screw, remove the electrical wire from the adjusting screw 30 for the amount of idling mixture and unscrew the screw 30. Remove the plastic plug 26 with a corkscrew and unscrew the adjusting screw 28 for the quality (composition) idle mixture. Remove cover 5 of the power mode economizer, diaphragm 6 and spring. Unscrew the fuel jet 7 of the economizer for power modes. Unscrew the main air jets 12 with emulsion tubes and the main fuel jets 13 of the main metering systems.

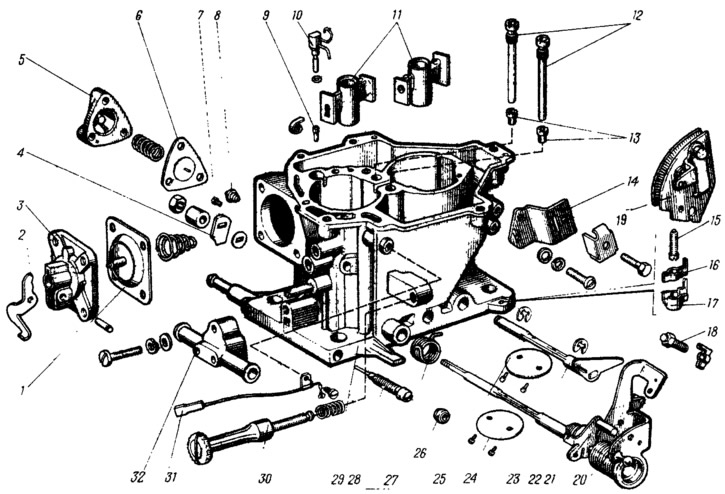

Pic. 53. Details of the carburetor body:

1 - accelerator pump diaphragm; 2 - accelerator pump drive lever; 3 - cover; 4 - accelerator pump drive cam; 5 - power modes economizer cover; 6 economizer diaphragm; 7 - economizer fuel jet; 8 - economizer valve; 9 - check valve of the accelerator pump; 10 - sprayers of the accelerator pump with a fuel supply valve; 11 - sprayers; 12 - main air jets with emulsion tubes; 13 - main fuel jets; 14 - bracket for fastening the shell of the draft of the air damper drive; 15 - adjusting screw of the second chamber; 16 - adjusting screw stopper: 17 - stopper cap; 18 - adjusting screw for slightly opening the throttle valve of the first chamber; 19 - carburetor throttle control sector; 20 - axis of the throttle valve of the first chamber with drive levers; 21 - lock lever of the second chamber; 22 - lock lever spring; 23 - axis of the throttle valve of the second chamber with a lever; 24 - throttle valve of the first chamber; 25 - throttle valve of the second chamber; 26 - plug quality adjusting screw (composition) mixtures; 27 - return spring of the throttle actuator lever of the second chamber; 28 - quality adjustment screw (composition) idle mixtures; 29 - carburetor body; 30 - adjusting screw for the amount of idle mixture; 31 - electrical wire of the forced idle economizer limit switch; 32 - carburetor heating block.

If necessary, unscrew the screws securing the throttle valve of the first chamber, remove the valve and remove the axle 20 as an assembly with the drive levers. After removing the lock washer and unscrewing the screws securing the throttle valve of the second chamber, remove the damper and remove the damper axle. Take out the bearings of the axes of the throttle valves of the first and second chambers.

Cleaning carburetor parts

Wash the carburetor fuel filter in gasoline and blow with compressed air. Check filter condition. If the filter or fuel supply pipe is damaged, replace it with new ones.

Rinse the parts of the float mechanism in gasoline, check their condition. On the sealing surface of the needle valve and its seat, no damage is allowed that violates the tightness of the valve. The valve should move freely in its seat, and the ball should not hang. The mass of the float must not exceed 6.23 g. Replace defective parts with new ones.

Clean the carburetor cover and all holes and channels in it from dirt and oil. Wash the cap in acetone or petrol and blow it out with compressed air. Inspect the sealing surfaces of the cover. If there is damage, replace the cap with a new one.

Clean all parts of the starting device, rinse with gasoline and blow with compressed air. Inspect parts, replace damaged.

Clean jets and emulsion tubes from dirt and resinous compounds, wash them with acetone or gasoline and blow with compressed air. Do not clean the jets with a metal tool or wire, and also wipe the jets and other parts of the carburetor with cotton, cloth or rags, as the villi can clog the jets and channels. In case of severe clogging, you can clean the jets with a soft wood needle moistened with acetone.

Clean the carburetor body from dirt and oil. Rinse its channels with acetone or gasoline and blow with compressed air.

Wash the parts of the accelerator pump in gasoline and blow with compressed air. Check the ease of movement of the ball in the atomizer and the mobility of the elements of the accelerator pump (lever, diaphragm parts). Eating is not allowed. The diaphragm must be intact.

Assembly and installation of the carburetor

The carburetor is assembled in the reverse order. At the same time, attention is paid to the mobility of the float on the axis, the ease of movement of the needle valve. In order not to confuse the jets during assembly, it is necessary to look at the marking of the jets and, when installing them, be guided by the table of basic data given earlier.

After tightening the screws for fastening the throttle valves on the axles, caulk the screws, preventing the axles from being deformed.

When assembling the accelerator pump, it is necessary to first tighten the cover fastening screws, press the drive lever all the way, tighten the screws and release the lever.

Install the carburetor in reverse order. Before installing, check the flatness and cleanliness of the planes of the connection between the intake manifold and the carburetor. Do not tighten the nuts of the heated carburetor.

After installing the carburetor, adjust the drive of its control, replace the air filter and adjust the engine idling.