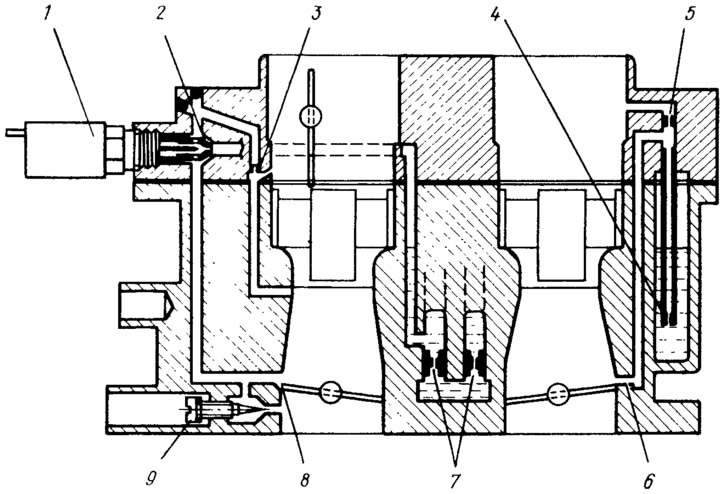

Pic. 48. Scheme of the idle system and transitional systems:

1 - electromagnetic shut-off valve; 2 - idle fuel jet; 3 - idle air jet; 4 - fuel jet of the transition system of the second chamber; 5 - air jet of the transition system of the second chamber; 6 - outlet of the transition system of the second chamber; 7 - main fuel jets; 8 - slot of the transition system of the first chamber; 9 - quality adjusting screw (composition) idle mixture.

When the engine is idling, the throttle valves are closed, the vacuum from under the throttle valve of the first chamber will be transmitted to all channels of the system. Under the action of vacuum, the fuel enters from the float chamber through the main fuel jet 7 of the first chamber and the emulsion well, rises through the fuel channel to the fuel jet 2 (while the jet is not closed by solenoid valve 1), the jet passes, mixes with air from the jet 3 and exits through the emulsion channel in the form of an emulsion under the quality adjusting screw 9 (composition) mixture into the throttle space, Additionally, on the path of the emulsion through slot 8, air is sucked in from the mixing chamber. Blend quality (compound) at idle, it is regulated by screw 9, and the amount of the mixture is regulated by the mixture amount screw, when screwed in, the throttle valve opens slightly.

When the ignition is turned off, the solenoid valve 1 is turned off, the valve needle closes the fuel jet 2 under the action of the spring and prevents the system from operating with the ignition off when the engine overheats.

Transition systems

Transitional systems of the first and second chambers provide a smooth transition from one engine operation mode to another at the moment of opening the throttle valve of the first chamber, and then the second chamber.

The transition system of the first chamber includes a slot 8 (see fig. 48), located just above the closed throttle, and elements of the idle system. At the moment the throttle valve begins to open, the gap falls under vacuum. The emulsion begins to flow not only under screw 9, but also through the slot under the throttle valve, preventing depletion of the combustible mixture. The emulsion flow rate increases to compensate for the increase in air flow in the carburetor mixing chamber. As the throttle valve opens, the gap opening increases and, accordingly, the amount of emulsion increases until the main dosing system comes into operation, thereby eliminating «failures» in engine operation.

The transition system of the second chamber consists of a fuel jet 4 with a tube, an air jet 5, an emulsion channel with outlets 6 above the throttle in the closed position. The air jet is connected by a channel to the air pipe of the second chamber. At the moment the throttle valve starts to open, holes 6 fall into the vacuum zone. Fuel is sucked from the float chamber through the jet, rises up the tube, mixes with air from the air jet and exits in the form of an emulsion through the emulsion channel through the holes for the throttle valve of the second chamber, ensuring a smooth transition to the operation of the main dosing system.