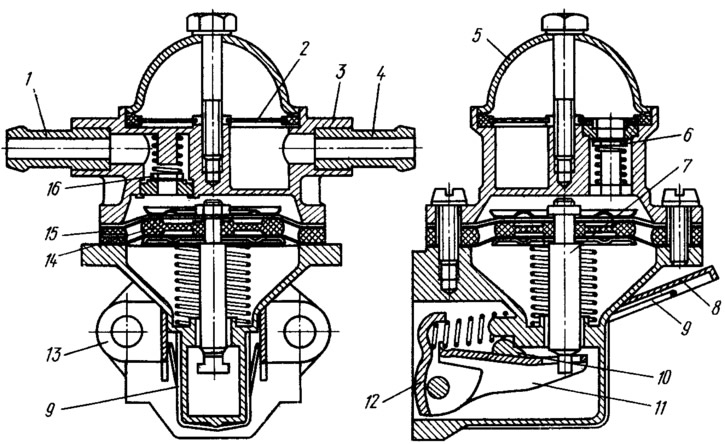

Pic. 40. Fuel pump:

1 - discharge pipe; 2 - filter; 3 - upper body; 4 - suction pipe; 5 - cover; 6 - suction valve; 7 stem; 8 - lever for manual fuel pumping; 9 - spring; 10 cam; 11 - balancer; 12 - mechanical fuel pumping lever; 13 - lower body; 14 - internal spacer; 15 - spring spacer; 16 - discharge valve.

The fuel pump consists of a lower housing 13 with drive levers, an upper housing 3 with valves and pipes, a diaphragm assembly and a cover 5. Three diaphragms are installed between housings 3 and 13: the upper two - working - for supplying fuel, the lower - safety - to prevent ingress of fuel into the drive housing in case of damage to the working diaphragms. Diaphragms are made of membrane fabric. Between the working and safety diaphragms there are outer 15 and inner 14 spacers. The outer gasket has a hole for fuel to escape to the outside in case of damage to the working diaphragms. Diaphragms with plates are mounted on stem 7 and fastened from above with a nut. There is a compressed spring on the stem under the diaphragm assembly. The rod with a T-shaped shank is inserted into the slot of the balancer 11, which allows you to remove the diaphragm assembly without disassembling.

In the lower case, levers 12.8 and a balancer 11 are installed. In the upper case 3, valves are installed: suction 6 and discharge 16. Gaskets made of diaphragm material are placed under the valves. The valves are pressed against the seats by springs. From above, a cover 5 is attached to the pump housing with a central bolt. A plastic mesh filter is installed between the cover and the housing. The upper housing 3 has a discharge 1 and suction 4 pump nozzles.

When the engine is running, the camshaft eccentric through the pusher acts on the lever 12 and turns the balancer 11, which pulls the pump diaphragms. In this case, the diaphragm spring is compressed. The diaphragms create a vacuum, as a result of which the fuel through the suction valve 6 fills the working cavity of the pump above the diaphragms. When the eccentric runs off the pusher, the lever 12, the balancer 11 and the rod with diaphragms are released. The diaphragms, under the action of a spring, create pressure in the working cavity, close the suction valve 6 and supply fuel to the carburetor through the discharge valve 16.

With a small fuel consumption, the diaphragm stroke is incomplete, so the lever stroke with the balancer will be partially idle.

The supply of fuel by the lever 8 of manual pumping is carried out by the action of the cam 10 on the balancer And and the diaphragm of the fuel pump.

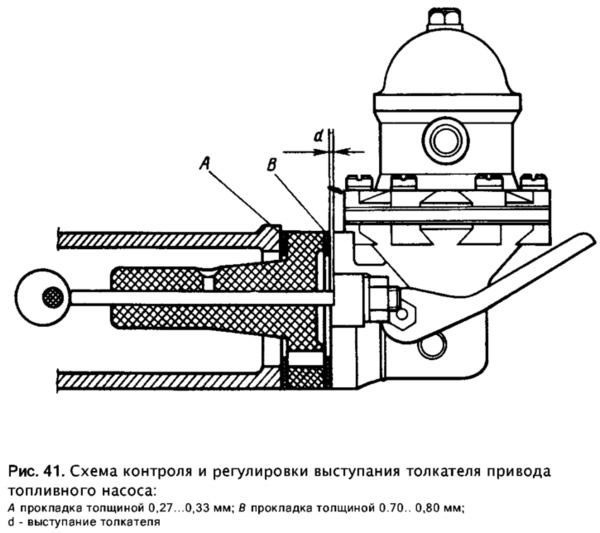

A heat-insulating spacer and shims are installed between the pump and the drive housing. For proper installation of the pump, two of the three gaskets below are used: gasket A - 0.27... 0.33 mm thick; gasket B - 0.7... 0.8 mm thick; gasket C - 1.1... 1.3 mm thick. The setup diagram is shown in fig. 41.

The pump is installed in the following order. A heat-insulating spacer is installed by placing gasket A under it, and gasket B is placed on the plane in contact with the pump. Measure the distance d (the minimum amount that the pusher protrudes, set by slowly turning the crankshaft). If the size d is in the range of 0.80... 1.30 mm, then the pump is attached to the engine; if d is less than 0.80 mm, gasket B is replaced by gasket A; if d is greater than 1.30 mm, then gasket B is replaced with gasket C. Dimension d is measured again and the pump is mounted on the engine.

Gasket A must always be placed between the drive housing and the heat-insulating spacer.