Attention! When checking with a voltage of 220 V, be careful not to touch parts of the starter that are energized with your hands.

1. Clean all starter parts.

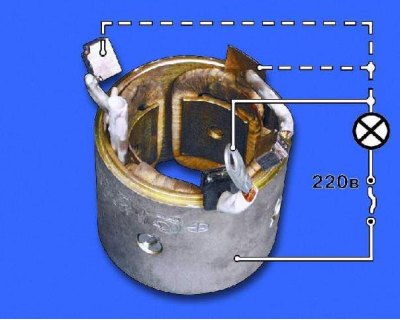

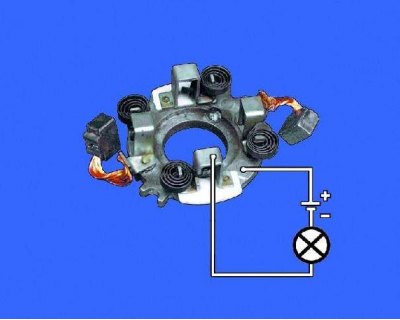

2. Check the condition of the stator winding. To do this, turn on the test lamp in an alternating current circuit with a voltage of 220 V and connect the wire to one of the stator winding terminals, close the other end of the circuit to the housing. If the lamp is on, then the insulation of the winding is damaged. Replace winding or stator. Check the second winding in the same way (see note).

The stator windings can be checked with a megger. Connect one lead to the terminal and the other to the stator housing. Winding resistance must be at least 10 kOhm. If it is less, replace the stator.

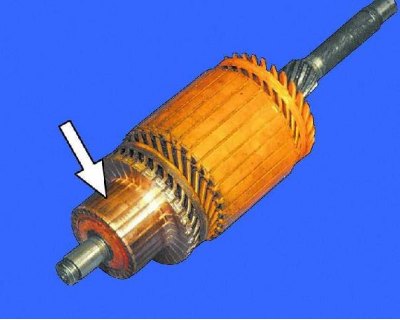

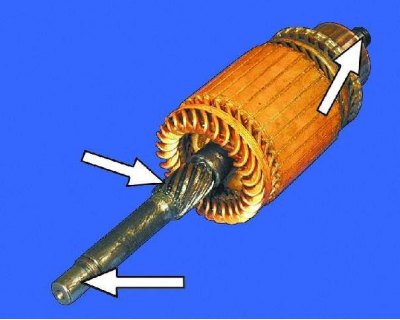

3. Examine the anchor. If the collector is dirty or has marks, scratches, etc., sand it with fine glass sand. With a significant roughness of the collector or if there are protrusions of mica between the plates, machine the collector on a lathe and then grind it with fine glass sandpaper. The runout of the core relative to the pins of the shaft should not exceed 0.08 mm. If the runout is greater, replace the armature.

4. If a yellow coating from the bearing is found on the armature shaft, remove it with a fine sandpaper, otherwise this will cause the gear to seize on the shaft. If there are scuffs or nicks on the surfaces of the pins and splines of the shaft, replace the anchor.

5. Check the reliability of the soldering of the armature winding leads to the collector plates. Inspect the winding at the ends of the armature: the diameter of the winding should be less than the iron package of the armature. If the diameter is larger, replace the anchor.

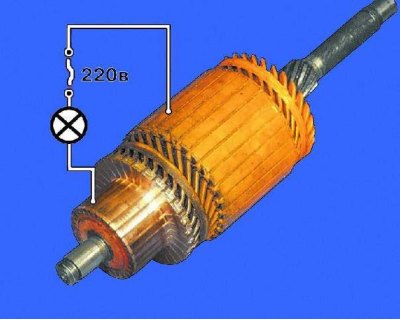

6. Check the condition of the armature winding with a test lamp in the 220 V AC circuit. Connect the wires to the collector plate and the armature core. If the lamp lights up, then there is a short circuit in the armature winding or collector plate on "mass". In this case, you need to replace the anchor (see note).

Step 6 Note: The armature windings can be checked with a megger. Connect one of its contacts to the collector, the other to the armature core. Winding resistance must be at least 10 kOhm. If there is less resistance, replace the armature.

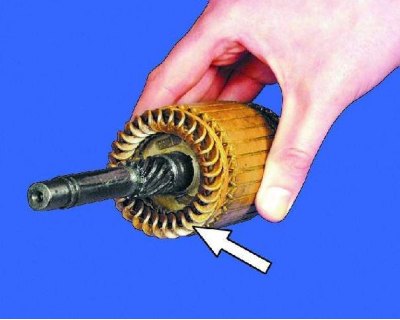

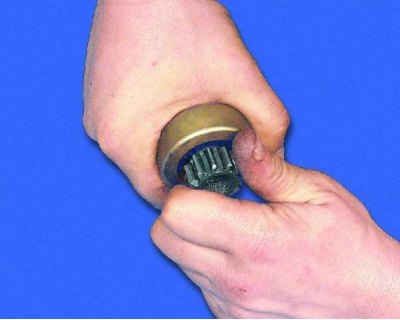

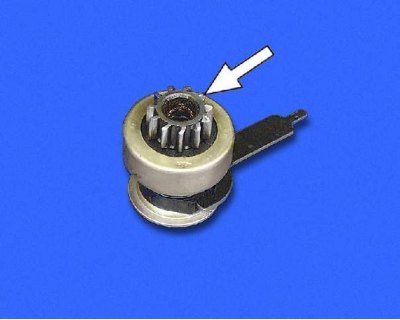

7. While holding the freewheel, try to turn the starter gear in both directions: it should rotate freely in a clockwise direction only. If the gear rotates in both directions, replace the drive.

8. Slide the starter drive onto the armature shaft. It should freely, without jamming, move along the splines of the shaft.

9. If drive parts are severely worn or damaged, replace drive. If nicks are found on the engagement part of the gear teeth, grind them with a fine-grained emery wheel of small diameter.

10. Examine a cover of a starter from a collector and an intermediate support. If cracks appear on these parts, replace them. Also inspect the bushings in the cover and in the support in which the armature shaft rotates. If severe wear or mechanical damage is found, replace the cover or support with defective bushings.

11. Inspect the bushing pressed into the clutch housing. If the bushing is worn or has nicks, pits, etc., replace the bushing.

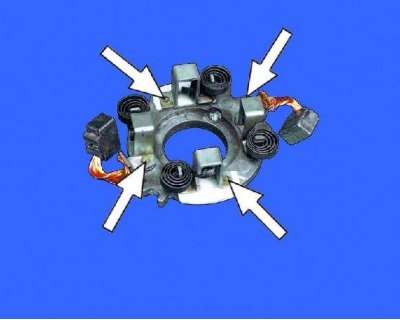

12. Brushes worn to a height of less than 12 mm must be replaced.

13. Check the movement of the brushes in the holders: the brushes should move easily, without jamming. Check the fastening of the brush holders: they must be firmly fixed.

14. Holders of insulated brushes must not have a short to ground. Check this with a test lamp.

15. Check up force of the springs pressing brushes, by means of a dynamometer. To do this, insert the anchor into the cover on the drive side, install the housing and brush holder. Insert the brushes into the brush holders. At the moment of separation of the spring from the brush, the force should be in the range of 9.0–11.0 N (0.9–1.1 kgf).

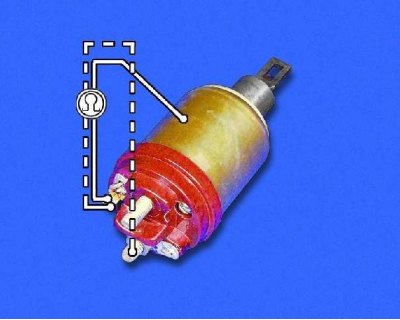

16. Check the resistance of the windings of the traction relay with an ohmmeter. The resistance of the retracting winding should be in the range of 0.52–0.59 ohms (Red color), and holding - 0.725–0.795 Ohm (yellow) at an ambient temperature of 15 to 25°C. The armature of the traction relay must move freely in the housing, without jamming.

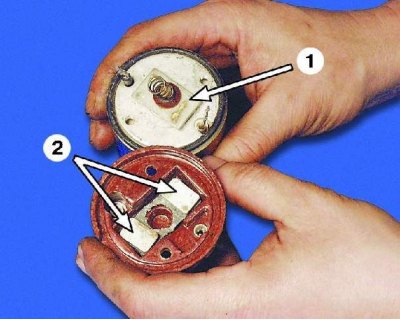

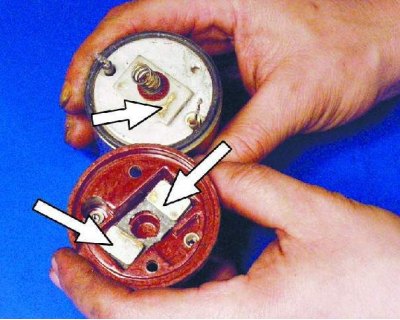

1 - contact plate

2 - rectangular heads of contact rings

Note. Simultaneously with checking the resistance of the winding, check whether the contact plate closes the contact bolts of the traction relay. If the ohmmeter shows "∞", then either a break in the winding, or the plate does not close the contact bolts. In both cases, the traction relay must be replaced.

17. Check the contact bolts. Clean the burnt heads of the bolts with a fine sandpaper. If the heads are severely burned out, the bolts can be rotated 180°so that they are pressed against the contact plate with the unburned side. If the surface of the contact plate is heavily worn, then it can be turned to the other side of the contact bolts.