- jerk - short-term spontaneous change in engine speed, regardless of the position of the pedal "gas". In daily operation, as a rule, there are a series of jerks;

- failure - a noticeable delay in the response of the engine to pressing the pedal "gas". Approximately, it can be considered as the limiting case of a jerk.

Conventionally, three types of jerks can be distinguished:

- at the moment of the beginning of the movement;

- during acceleration;

- with steady motion, i.e. with constant pedal position "gas".

Attention! When using a carburetor DAAZ "Solex" there is a very unpleasant defect: when you press the pedal "gas" there is a strong failure, the engine stalls, often there is no idling. Movement is possible only when the pedal is pressed "gas" to the floor or accounted for continuously "sway" pedal. The reason is clogging of the fuel jet of the main metering system of the first chamber.

Experienced car enthusiast it is necessary to remove the top cover of the carburetor, as described above, unscrew the two air jets, unscrew the two fuel jets with a thin screwdriver and remove them from the wells with a long wooden toothpick or pointed stick. Do not mix up the jets when reinstalling! Then, with a syringe or a clean, lint-free rag, remove gasoline from the float chamber and blow the carburetor with compressed air, especially carefully - the wells of the fuel jets.

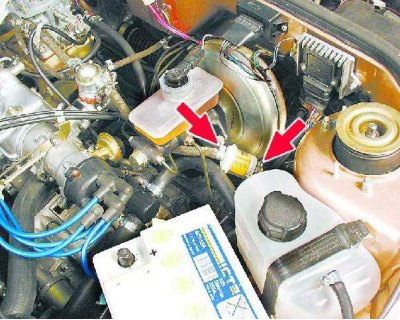

For an inexperienced car enthusiast it is better to immediately contact a car service. To get to the service, cut a piece of PVC tubing 1–1.5 cm long (at least from the washer tubes) and put on the second chamber drive stop lever. The engine speed will be approximately 2000 min–1. Use the clutch and brake pedals to maintain a safe speed.

Jerk at the moment of the beginning of the movement

At the moment of the beginning of the movement, there is more often an extreme case of a jerk - a failure. The most unpleasant sensations are associated precisely with the delay in the response of the engine to pressing the pedal "gas". Sometimes the engine even stalls.

The cause of the failure may be either a malfunction of the carburetor accelerator pump, or a malfunction of the vacuum corrector of the ignition distributor.

Required for work: wrenches on "8" And "10", Phillips and slotted screwdrivers, a clean rag, a piece of thin copper wire with no insulation with a diameter of less than 0.3 mm, a compressor, a can of WD40 liquid, possibly a portable lamp.

1. Remove the air filter housing cover by unscrewing the nut with a spanner "10" and unfasten the spring clips.

Remove the air filter. Loosen the four nuts with a spanner "8", use a screwdriver to loosen the crankcase ventilation hose clamp at the connection to the valve cover and remove the air filter housing.

2. Disconnect the vacuum corrector drive hose of the ignition distributor and, creating a vacuum with your mouth, check the tightness.

Does air flow freely?

No: see point 4.

3. Contact a car service to replace the vacuum corrector of the ignition distributor.

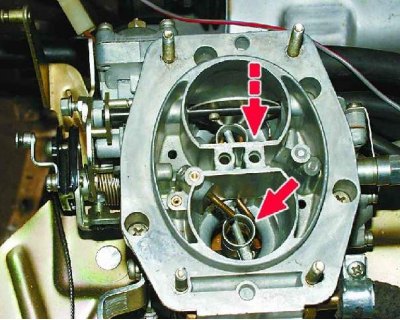

4. Look inside the carburetor. The air damper must be fully open. Press the throttle control lever. A trickle of fuel should appear from both tubes of the accelerator pump sprayer. The jets should be even and directed into the gap between the diffuser wall and the opening damper. If necessary, use a portable lamp.

Are there jets?

Is the fuel spray direction correct?

No: see point 6.

5. Contact a car service for diagnostics.

6. Without spilling fuel, remove the fuel supply hose to the carburetor and the fuel drain hose. Remove the choke control cable and wire from the idle air solenoid valve. Remove the five screws securing the top cover of the carburetor.

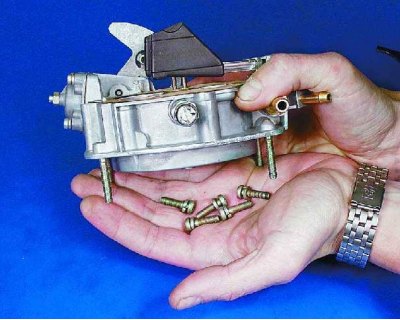

Remove the carburetor cap, carefully invert (the mounting screws will fall out - do not lose them!) and place it upside down.

Warning! Do not damage the floats!

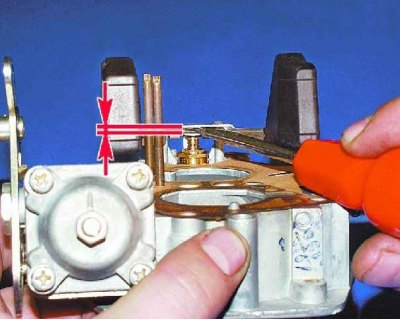

7. Gently pry with a screwdriver as close as possible to the place where the accelerator pump atomizer tube is terminated and, pressing from the bottom up, remove the atomizer from the socket.

8. Clean both holes of the atomizer jet with a thin copper wire.

Blow the atomizer with air in the direction opposite to the direction of fuel flow.

9. Insert the atomizer into place. Without installing the carburetor cover, press the throttle control lever. A trickle of fuel should appear from both tubes of the accelerator pump sprayer.

Are there jets?

No: see point 11.

10. Reassemble the carburetor and keep in mind that it's time to service it, replace the fuel fine filter or change the place of gas station.

11. Check the ease of movement of the accelerator pump drive lever and the absence of play in the drive. If necessary, lubricate the parts with WD40 type fluid, replace the defective parts. Check the operation of the accelerator pump again.

Are there jets?

No: see point 13.

12. Reassemble the carburetor and keep in mind that it's time for maintenance.

13. Contact a car service for diagnostics and repairs.

Jerks during acceleration

The cause of jerking may be a low fuel level or a clogged fuel filter in the carburetor, a fuel pump malfunction or a clogged additional fuel filter, or a malfunction of the ignition system.

Required for work: wrenches on "8", "10" And "13", Phillips and slotted screwdrivers, a clean rag, a piece of thin copper wire with no insulation with a diameter of less than 0.3 mm, a compressor, a can of WD40 liquid, possibly a portable lamp.

1. Remove the air filter housing cover by unscrewing the nut with a spanner "10" and unfasten the spring clips.

Remove the air filter. Loosen the four nuts with a spanner "8", use a screwdriver to loosen the crankcase ventilation hose clamp at the connection to the valve cover and remove the air filter housing.

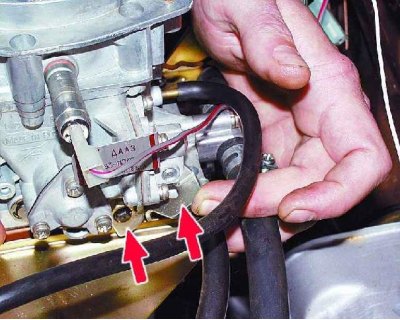

2. Without spilling fuel, remove the fuel supply hose to the carburetor and the fuel drain hose. Remove the choke control cable and wire from the idle air solenoid valve.

Remove the five screws securing the top cover of the carburetor. Remove the carburetor cap, carefully invert (the mounting screws will fall out - do not lose them!) and place the lid upside down.

Warning! Do not damage the floats!

Look inside the carburetor. The gasoline level should be about 22-23 mm below the cap connector and carburetor body.

Is the level normal?

Yes: see point 4.

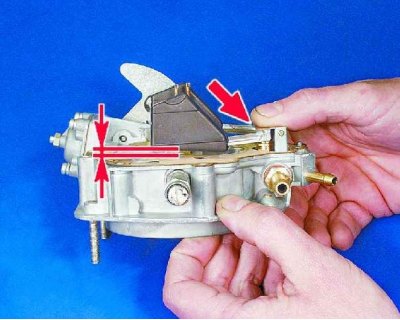

3. Adjust the fuel level by bending the float. To do this, gently press your thumb on the float bracket where it touches the carburetor needle valve. The gap between the cover gasket and the floats should be 1.5–2 mm.

If the fuel level is high (clearance between cover gasket and floats less than 1mm), use a screwdriver to bend the tongue of the float bracket and increase the gap.

4. Key on "13" unscrew the carburetor fuel filter plug.

Remove the plug together with the mesh filter and take out the filter.

Warning! Don't lose the copper O-ring!

Inspect the filter carefully.

Do you have any doubts about the cleanliness of the filter?

No: see point 6.

5. At the slightest doubt, wash the filter with gasoline and blow it with compressed air inside and out. A heavily soiled filter should be replaced.

6. Check additional fuel filter.

Do you have any doubts about the cleanliness of the filter?

No: see point 8.

7. At the slightest doubt, it is better to replace a dirty filter.

8. Reassemble the carburetor in reverse order and test drive.

Are the fish left?

Yes: see point 11.

10. Bon Voyage!

11. Fuel pump malfunction - too little fuel pressure, or a malfunction of the ignition system. The need for diagnostics go to car service. The only thing you can try to do yourself is to replace the spark plugs, regardless of mileage and condition. Pay attention to the condition of the candles - if it is abnormal, you may need to contact a car service (cm. "Diagnostics of the engine condition by the appearance of spark plugs").

Jerks in steady motion

Such jerks are often caused by a malfunction of the ignition system. The need for diagnostics go to car service. The only thing you can try to do yourself:

- carefully inspect the underhood space. Turn off the ignition and check the reliability of fastening and landing of all wires and connectors at the switch, coil and ignition distributor. Start the engine and listen to its work - crackling during a breakdown of high voltage "to ground" weak but distinct. In complete darkness, a spark is clearly visible during breakdown;

- replace spark plugs regardless of their condition and mileage. Pay attention to the condition of the candles - if it is abnormal, you may have to go to car service.