1. Loosen the mounting screw and disconnect the heating fitting from the carburetor. If the screw cannot be removed, loosen the clamp and remove the hose from the fitting.

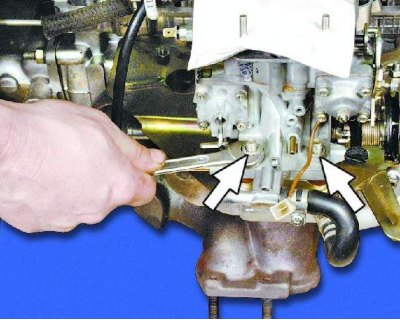

2. Loosen the four nuts securing the carburetor (two of them are located on the opposite side).

3. Remove the carburetor from the intake pipe.

4. Carefully remove the carburetor gaskets.

5. Loosen the two nuts securing the carburetor heat shield.

6. Loosen the nut on the fitting.

7. Remove the heat shield.

8. Loosen the two nuts securing the hot air intake pipe.

9. Loosen the ring nut.

10. Remove the eye and the warm air intake pipe.

11. Remove the nine nuts securing the intake pipe and exhaust manifold.

12. Remove the exhaust manifold.

13. Remove the intake pipe.

14. Remove two gaskets (see note).

Note. Remove gaskets carefully. If the gaskets are not damaged and not heavily compressed, they can be reused. Carefully pry off burnt gaskets with a screwdriver.

Note. After removing the exhaust manifold and intake pipe, place wooden shims under the head of the block so as not to damage the valves protruding from the head of the block.

15. Remove spark plugs.

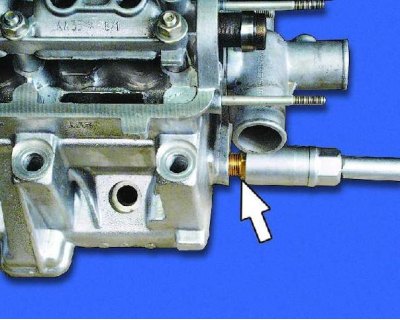

16. Remove the coolant temperature sensor.

17. Turn out the gauge of a control lamp of emergency pressure of oil.

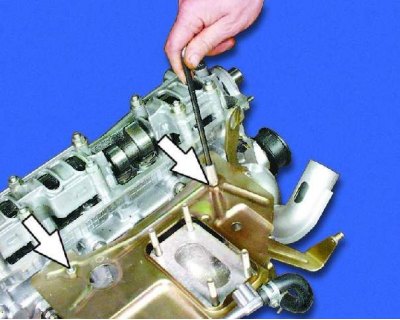

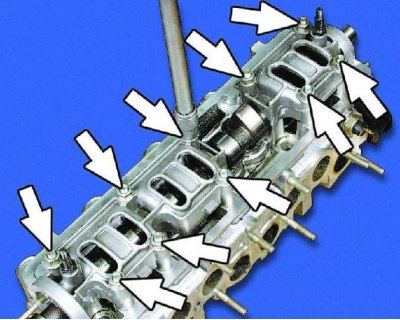

18. Remove the ten nuts securing both camshaft bearing housings.

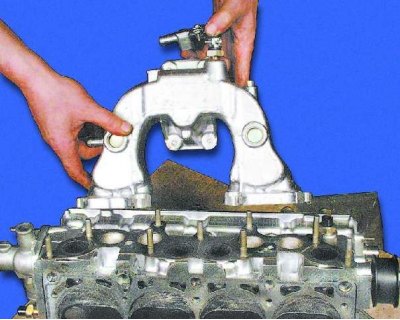

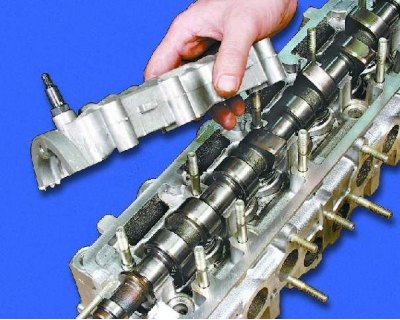

19. Remove both camshaft bearing housings from the cylinder head.

20. Remove the camshaft.

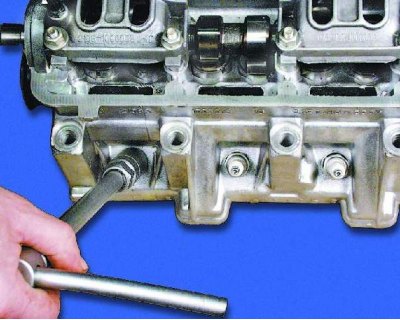

Warning. Having taken out the next pusher, mark it and the adjusting washer with a serial number in order to install them in their place during assembly.

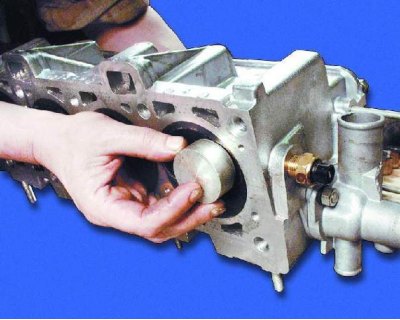

21. Remove the oil seal from the front end of the camshaft.

22. Turn away a nut of fastening of a tension roller.

23. Remove the tension roller and the thrust washer installed under it.

24. Take out pushers of valves together with adjusting washers.

Valve actuator details: 1 - exhaust valve; 2 - inlet valve; 3 - outer spring; 4 – internal spring; 5 - a plate of springs; 6 - crackers; 7 - spring washer

25. Mark the valves with the cylinder number so that they can be reinstalled when reassembling. Marking can be applied with a core as close as possible to the center of the valve: the valves of the first cylinder - one point, the second - two, etc.

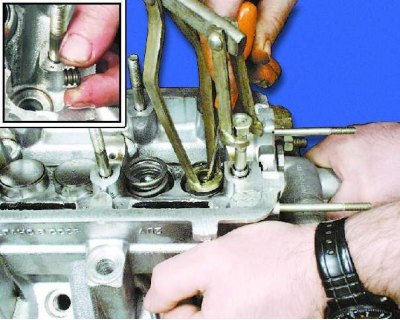

26. Place a suitable stop under the valve to be removed.

27. Install the valve spring compressor on the head. Compress the valve springs with it and remove the crackers. Gradually loosening the pressure on the tool handle, fully decompress the valve spring and remove the tool from the head.

28. Remove the outer spring with the plate.

29. Remove the inner spring.

30. Remove the valve from the block head.

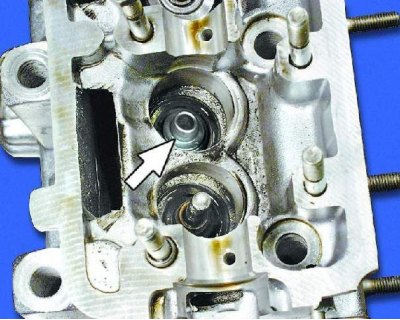

31. Carefully remove the valve stem seal without damaging the valve guide.

32. Take out the support washer (plate) valve springs. Remove the rest of the valves in the same way.