Clearance is measured on a cold engine (at 20°C) between the camshaft cam (the cam must be pointing up from the pusher) and adjusting washer of the valve lifter.

The nominal clearance for the intake valve is (0,2+0,05) mm, for graduation - (0,35+0,05) mm. The gaps are adjusted by selecting the thickness of the shims. As spare parts, washers with a thickness of 3 to 4.5 mm are available in increments of 0.05 mm.

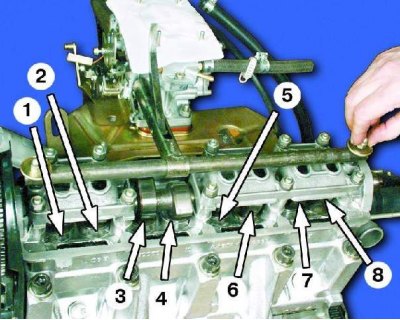

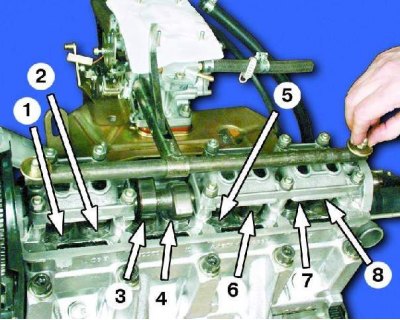

Counting from the camshaft drive, the first, fourth, fifth and eighth valves are exhaust; the second, third, sixth and seventh are inlet.

Notes. It is recommended to unscrew the spark plugs to make it easier to turn the crankshaft.

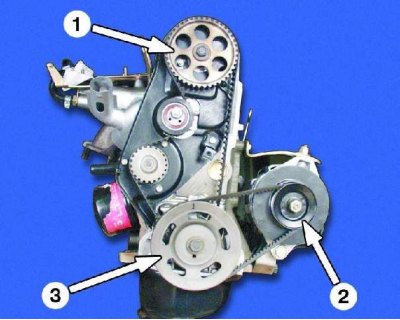

1 - camshaft gear

2 - generator pulley

3 - crankshaft pulley

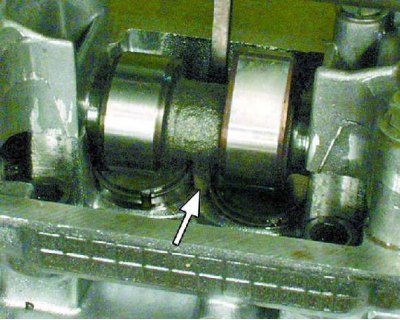

The retainer must be installed between the camshaft and the end of the tappet.

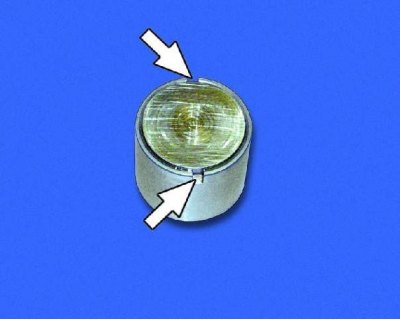

In order to make it easier to remove the adjusting washer, two grooves are machined in the pusher. Turn the pusher so that it is more convenient to pick up the washer.

The thickness of the new washer is calculated by the formula: H = B + A - C,

where A is the measured gap, mm;

B is the thickness of the old washer, mm;

C – nominal gap, mm;

H is the thickness of the new washer, mm.

Example (for intake valve): A=0.26mm, B=3.75mm, C=0.2mm, then

H = 3,75 + 0,26 – 0,2 = 3,81 (mm).

Within the clearance tolerance of +0.05 mm, we select the closest washer in thickness (3.8mm).

Attention! Turn the crankshaft clockwise with a wrench on the crankshaft pulley bolt or alternator pulley bolt. Do not turn the crankshaft using the camshaft pulley bolt.

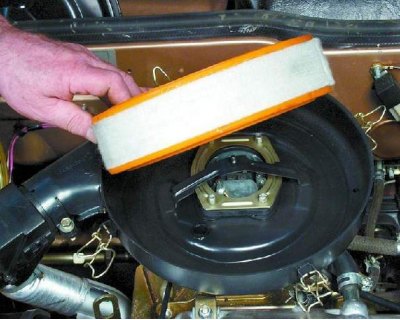

1. Loosen the filter cover nut and remove the washer.

2. Release the four spring clips.

3. Remove the air filter cover.

4. Remove the filter element from the housing.

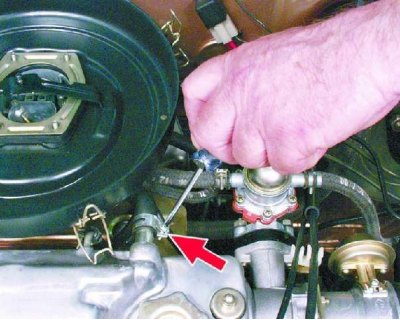

5. Loosen the clamps and remove the hoses from the nozzles on the valve cover.

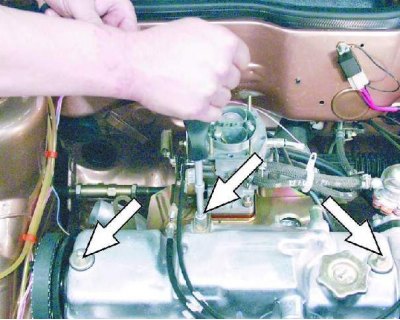

6. Remove four nuts.

7. Remove the filter housing and the warm air intake hose from the nozzle from the studs. Disconnect the hose from the filter housing, after loosening the clamp.

8. Disconnect the plastic holder from the hose, loosen the clamp and remove the hose from the nozzle on the valve cover.

9. Loosen the nut and remove the accelerator cable bracket, leaving it hanging on the cable. Loosen the two cap nuts.

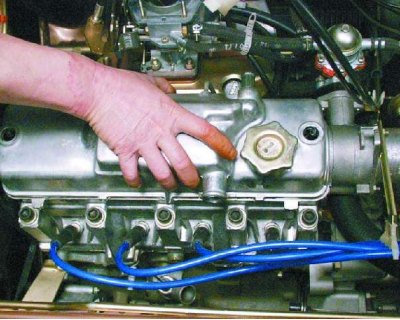

10. Remove the valve cover.

11. Remove oil from the top of the block head (around the valve lifters). Install tappet recessing tool onto valve cover studs and secure with nuts.

12. Remove the three bolts and remove the camshaft drive front cover.

13. Set the piston of the first cylinder to the top dead center. compression stroke. To do this, turn the crankshaft so that the mark on the camshaft pulley matches the mark (tendril) on the rear cover of the camshaft drive (see notes). Then turn the crankshaft another 40-50°. In this case, the camshaft cams will turn away from the pushers.

14. Measure the gaps at the first, second, third and fifth valves with a set of probes.

15. If the gap of any valve differs from the nominal, drown the pusher of this valve by pressing the fixture handle.

16. While holding the pusher in the recessed position, install the retainer (see notes).

17. Move the recessing device away from the pusher and remove the adjusting washer by prying it with a thin screwdriver (see notes).

18. Record the thickness of the shim that is marked on one side. If the thickness of the washer is not visible, measure it with a micrometer.

19. Install a new washer of the required thickness in the pusher (see notes). Install the washer with the inscription down (to the pusher). Drown the pusher with a tool and remove the retainer.

20. To check, measure the gap with a feeler gauge: if it differs from the nominal, repeat the adjustment.

21. Rotate the crankshaft one revolution (360°) and adjust the clearances of the fourth, sixth, seventh and eighth valves in the same order. Then pour oil into the top of the block head.

22. Install the front camshaft drive cover, valve cover, air filter and install the spark plugs. Tightening torques see Appendix 3.