The front suspension strut consists of a housing in which a hydraulic telescopic shock absorber is installed, a coil spring and an upper strut support. Outside, a bracket for attaching the steering knuckle, a swing arm and a lower spring support cup are welded to the strut body.

The coil spring rests with its lower coil on the lower support cup, and with its upper coil on the upper support cup fixed on the shock absorber rod. Also on the shock absorber rod, the upper support of the strut is installed, consisting of a housing, a rubber cushion and a bearing. The support body is attached to the car body with three nuts. The bearing allows the shock absorber rod to rotate in the support when the strut is turned, and the rubber buffer prevents the transmission of vibrations to the car body.

The shock absorber rod is protected from dirt and dust by a boot (corrugated casing). When the front suspension breaks down, the shock absorber's downward stroke is limited by the compression stroke buffer.

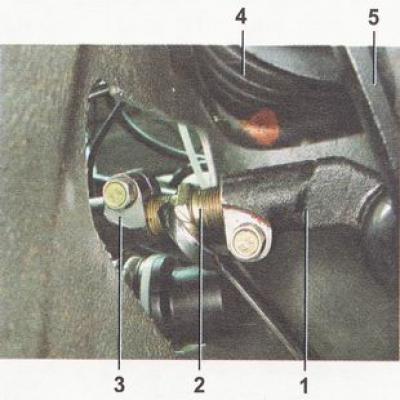

The strut pivot arm is connected to the tie rod via a ball pin. Changing the length of the rod with its threaded insert allows you to adjust the toe of the front wheels.

1 - tie rod end 2 - threaded insert; 3 - tie rod; 4 - telescopic stand; 5 - rotary lever

The steering knuckle is attached to the strut bracket with two bolts and nuts. The upper hole of the bracket is oval, and the bolt installed in it has an eccentric belt and an eccentric washer. When the top bolt is turned, the knuckle moves radially using the bottom bolt as the axis of rotation. Due to this, the angle between the strut and the fist changes, which in turn allows you to adjust the camber of the front wheel on the car.

1 - bracket for mounting the steering knuckle; 2 - rack body; 3 - top (eccentric) steering knuckle bolt; 4 - the lower bolt of fastening of a rotary fist; 5 - steering knuckle

A double-row ball bearing is pressed into the hole of the steering knuckle and fixed with two circlips. The wheel hub is pressed into the inner ring of the bearing.

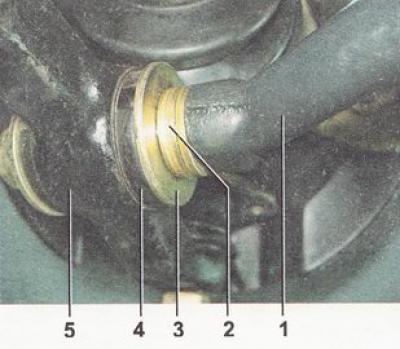

From below, the steering knuckle is connected to the transverse suspension arm by means of a ball joint. The transverse lever is kept from moving by an extension, which, with its rear end, is attached through a silent block (rubber-metal joint) to the lever, and the front ones - through the pillow to the cross member. By changing the number of washers in the front and rear fastening of the extension, you can change the position of the lever, thereby adjusting the angle of the longitudinal inclination of the axis of rotation.

1 - rear end of the longitudinal extension; 2 - adjusting washers; 3 - thrust washer; 4 - silent block (rubber-metal joint); 5 - transverse arm of the front suspension

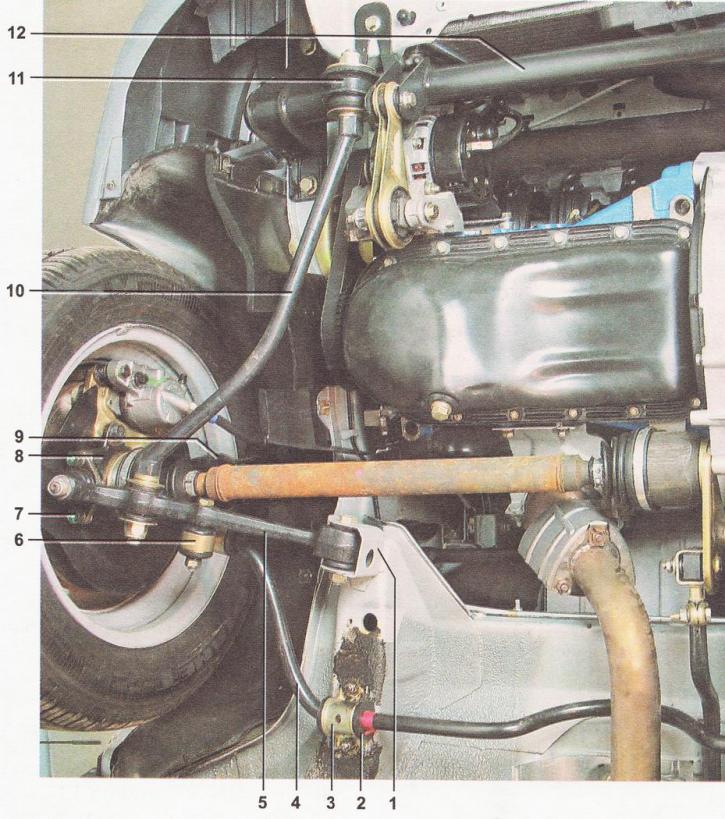

The ends of the anti-roll bar, with the help of struts, are connected to the transverse levers of the front suspension. The central part of the stabilizer is fixed through rubber pads on the body. The movement of one of the levers through the stabilizer is transmitted to the second. This allows you to partially synchronize the work of both sides of the suspension and thereby reduce the swaying of the car on rough roads and rolls in corners.

Front suspension device: 1 - bracket for fastening the transverse lever; 2 - stabilizer bar cushion; 3 - rod cushion bracket; 4 - stabilizer bar; 5 - transverse lever; 6 - stabilizer bar; 7 - ball bearing; 8 - rotary fist; 9 - telescopic stand; 10 - stretching the transverse lever; 11 - bracket for the front mounting of the extension of the transverse lever; 12 - cross member