- caliper;

- mandrel for piston rings.

Disassembly

1. Remove the piston rings from the piston (see "Piston rings - replacement").

2. With an awl, pry off the retaining ring of the piston pin...

... and remove the retaining ring from the groove.

3. Using a soft metal bar of suitable diameter, push the piston pin out of the piston.

4. Remove the piston from the connecting rod.

Selection of pistons and block cylinders

For new engines installed on cars, the clearance between the piston and the cylinder is 0.025-0.045 mm and is set by installing pistons of the same class as the cylinders.

Note. For correct use of the caliper, refer to the instructions supplied with the instrument.

With a bore gauge, we check the wear of the walls of the engine cylinders.

Measurements are carried out in four belts (5, 12, 62 and 112 mm from the top edge of the cylinder) in the longitudinal and transverse directions of the engine. In the upper belt, the cylinder does not wear out. By the difference in readings of the caliper in different belts, we determine the degree of wear of each cylinder.

Engine cylinder diameters are divided into five size classes (see table. 8.1.31.1). The class of each cylinder is stamped on the lower mating surface of the cylinder block.

Recommendation. Small uniform cylinder wear (within 0.05mm) you can try to compensate by installing a piston of another class with a larger diameter.

If the maximum wear of the cylinder is 0.15 mm or more, it is necessary to bore the cylinders and install oversized pistons.

Cylinder bore of 0.4 mm and 0.8 mm is provided for the dimensions of the repair pistons.

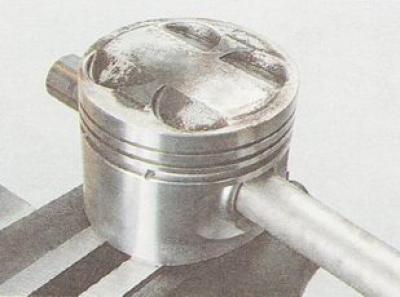

On the bottom of the piston are marked, where:

2 - hole class for the piston pin;

C - piston class;