The air entering the engine cylinders is cleaned of dust by an air filter. Air filter mounted in the engine compartment on three rubber mounts. The filter element of the filter is replaceable, made of special paper. To prevent the ingress of polluted air into the intake tract, there is a sealing border at the top of the element. To replace the filter element, the filter cover is made removable. Purified air through DMRV (mass air flow sensor) (see more details. "Engine control system - device, repair, diagram") passes through the air duct to the throttle valve.

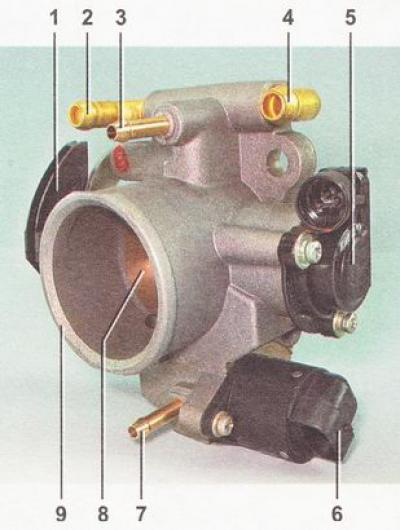

throttle valve regulates the amount of air entering the engine cylinders. Pedal throttle drive «gas» - cable. Throttle valve rotates on an axle in the housing (branch pipe). The throttle body is studded to the intake module flange. The housing has a channel for the coolant. The channel is connected to the cooling system by rubber hoses. The circulation of coolant through the throttle body prevents freezing of the internal air cavities of the body in winter. Fittings are installed in the housing for connection with the adsorber and the engine crankcase ventilation system.

Throttle body with TPS installed on it (throttle position sensor) and IAC (idle control) (see more details. "Engine control system - device, repair, diagram"), form throttle assembly.

The fuel supply is stored in a fuel tank with a capacity of 43 liters. Fuel tank - steel, welded from two stamped parts. The fuel tank is suspended from the bottom of the car on two steel clamps. The filler neck of the fuel tank is displayed on the right side of the car and is closed with a stopper. Fuel from the fuel tank is supplied by an electric fuel pump submersible type.

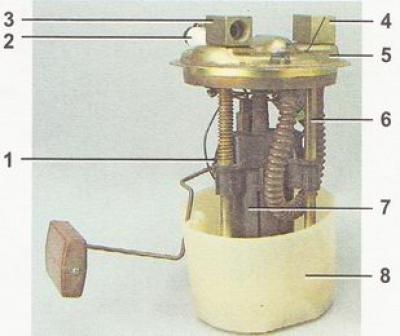

The fuel pump is installed in the fuel tank. To access the fuel pump in the bottom of the car under the rear seat cushions, a hatch with a cover is made.

A strainer is installed on the fuel pump inlet pipe to trap small solid particles of debris that have entered the fuel tank along with gasoline. The pump is energized by the ECU (see "Engine control system - device, repair, diagram") when the ignition is turned on. If at the same time no attempt is made to start the engine, then after 2-3 seconds the ECU will turn off the fuel pump.

Throttle assembly: 1 - throttle actuator sector; 2, 4 - fittings for connection with the engine cooling system; 3 - crankcase exhaust fitting; 5 - throttle position sensor; 6 - idle speed regulator; 7 - fitting for connection with the adsorber; 8 - throttle valve; 9 - branch pipe of the throttle body

Fuel pump: 1 - protrusion for attaching a mesh filter; 2 - fuel intake pipe for connecting a strainer; 3 - body; 4 - connector; 5 - day off (forcing) branch pipe for connection with the cover of the fuel module with a corrugated tube

Note. On a vehicle with an MP7.0 type ECU, the first attempt to start the engine after the battery is connected, the fuel pump can only be turned on simultaneously with the starter. In the future, the fuel pump will work as on vehicles with other types of ECU. However, after three ignitions in a row without starting the engine, the fuel pump will only be turned on at the same time as the starter.

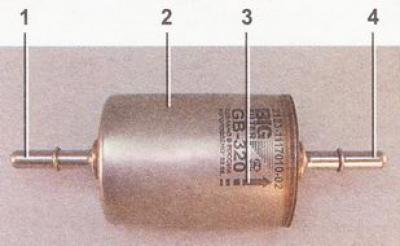

From the fuel pump through the corrugated tube of the fuel module (see below) gasoline enters the fuel line and then to the fuel filter, where the fuel undergoes a more thorough cleaning.

Fuel filter - paper, installed in a metal non-separable case.

The purified fuel enters the fuel rail through the fuel line.

Fuel filter engine VAZ 21124 (l,6i): 1 - inlet pipe; 2 - body; 3 - fuel flow direction arrow (painted on the filter body); 4 - outlet pipe

Note. Fuel filter engine VAZ 2112 (1,5i) has threaded fittings.

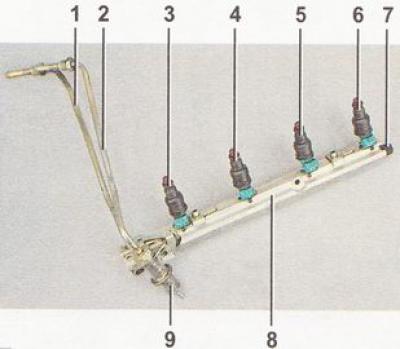

fuel rail holds four nozzles and brings fuel to them. The connection of the fuel rail with the injectors is sealed with rubber rings. The fuel rail is bolted to the cylinder head.

Fuel pressure control - a bypass valve that maintains in the system (fuel line) working pressure 284-325 kPa for the 2112 engine or 378-390 kPa for the VAZ 21124 engine, necessary for the correct operation of the injection system (see more details. "Engine control system - device, repair, diagram").

In accordance with the environmental requirements of EURO II, the car is equipped with fuel vapor recovery system, the above-fuel space of the fuel tank is connected with the atmosphere not directly, but through the elements of this system. The gasoline vapor recovery system consists of a separator, an adsorber, a gravity valve, an adsorber purge valve, a check valve, connecting pipes and hoses. The separator and gravity valve are fixed under the left rear fender of the car. Gasoline vapor is partially condensed in the separator and returned to the fuel tank. The gravity valve prevents fuel from escaping from the fuel tank when the vehicle is rolled over.

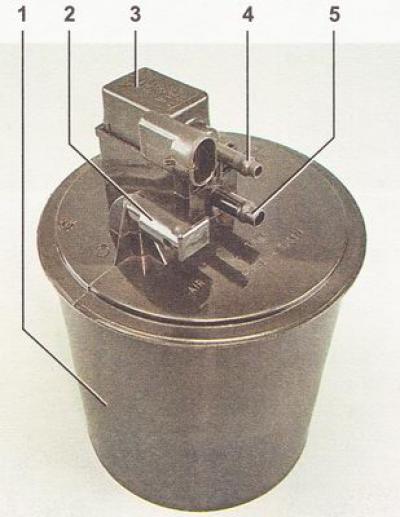

From the separator, uncondensed gasoline vapors through pipes and connecting hoses enter the adsorber, which prevents vapors from entering the atmosphere. An adsorber is a container where gasoline vapors are absorbed by activated carbon. When the engine is running at a high crankshaft speed, the ECU sends a signal to open the canister purge valve, and gasoline vapors are sucked into the intake module receiver.

Air to the intake valves of the VAZ 2112 engine cylinders (l,5i) supplied through receiver and inlet pipeline. These elements of the intake tract are interconnected by rubber couplings.

Fuel pump integrated with the fuel gauge sensor into a single unit - the fuel module (often referred to as an electric fuel pump). The pressurized fuel pump delivers fuel from the gas tank through the fuel filter to the fuel rail.

Fuel pressure control installed on the fuel rail. Excess fuel is returned to the gas tank through the fuel drain line.

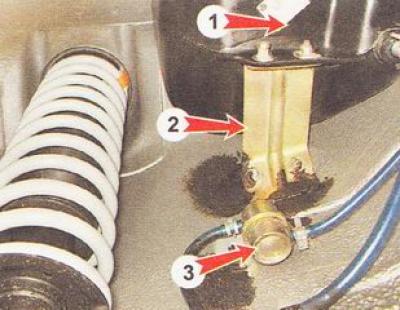

The location of the separator on a car with a VAZ 21124 engine (l,6i): 1 - separator; 2 - separator mounting bracket; 3 - gravity valve

Note. On a car with a VAZ 2112 engine, a safety valve is additionally installed here. On a car with a VAZ 21124 engine, the safety valve is made in the filler cap.

Adsorber: 1 - adsorber body; 2 - branch pipe for connecting the internal cavity of the adsorber with the atmosphere; 3 - adsorber purge valve; 4 - connecting branch pipe of the valve; 5 - adsorber connecting pipe

Fuel module of the VAZ 2112 engine (1,5i): 1 - fuel gauge sensor; 2 - connector; 3 - inlet pipe; 4 - day off (forcing) pipe branch; 5 - module cover; 6 - module cover guide; 7 - electric fuel pump in a plastic casing; 8 - intake chamber

Fuel rail of the VAZ 2112 engine (l,5i) complete with injectors: 1 - fuel supply pipe to the fuel rail; 2 - fuel line tube for draining fuel into the tank; 3, 4, 5 and 6 - nozzles; 7 - diagnostic fitting (for checking fuel pressure, closed with screw cap); 8 - fuel rail; 9 - fuel pressure regulator

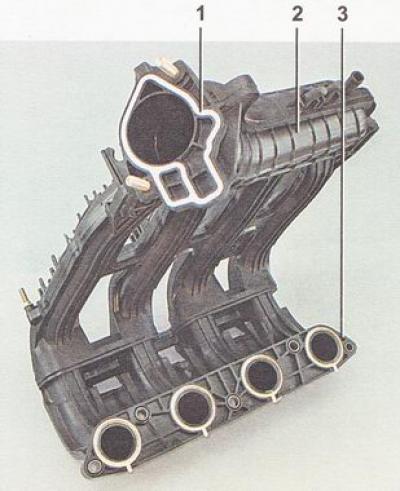

Intake engine module VAZ 21124 (l,6i): 1 - flange with a sealing ring for fastening the throttle pipe; 2 - receiver; 3 - intake manifold flange with sealing rings for connections to the cylinder head

Air is supplied to the intake valves of the engine cylinders through the intake module.

intake module engine VAZ 21124 is made of special plastic and is a non-separable element.

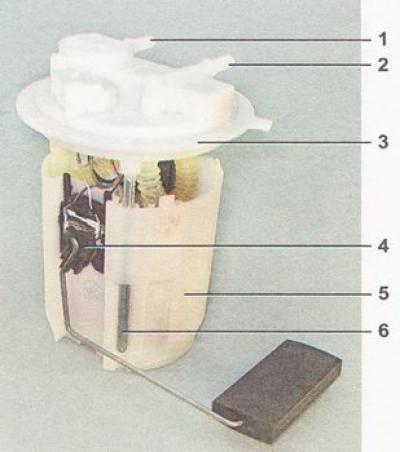

Fuel module of the VAZ 21124 engine (l,6i): 1 - inlet pipe (for supplying fuel to the pressure regulator); 2 - day off (forcing) pipe branch; 3 - module cover; 4 - fuel gauge sensor; 5 - intake chamber; 6 - module cover guide

The filler cap has two valves: one for emergency release of fuel vapor pressure from the tank (what happens when the ambient temperature rises), and the other - for the intake of air from the atmosphere when fuel is consumed from the gas tank (this eliminates the occurrence of a strong vacuum in the tank).

Fuel pump combined with the fuel level indicator sensor and the fuel pressure regulator into a single unit - fuel module (often referred to as an electric fuel pump).

Engine fuel pressure regulator VAZ 21124 (l,6i): 1 - hole for dumping excess fuel; 2, 4 - sealing rings; 3 - holes for supplying fuel to the regulator; 5 - body; 6 - output for connecting the regulator with «weight»

By car with a VAZ 21124 engine (l,6i) fuel from the pump (through the fuel module outlet) enters the fuel filter. The purified gasoline is again fed through the fuel line and through the tee to the inlet pipe of the fuel module and then fed into the fuel rail. Excess fuel is bled through the pressure regulator into the gas tank. The fuel pressure regulator is located in the fuel module cover.

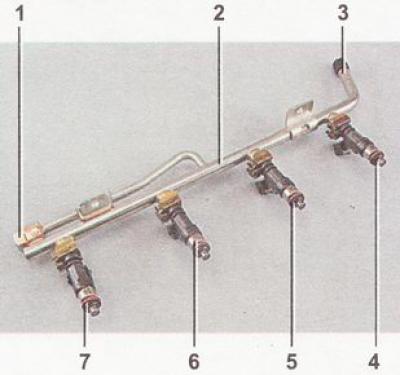

Fuel rail of the VAZ 21124 engine (l,6i) complete with injectors: 1 - fitting for connecting to the fuel line; 2 - fuel rail; 3 - diagnostic fitting (for checking the operating pressure, closed with a screw cap); 4, 5, 6 and 7 - nozzles

Features of the power supply system of the VAZ 2112 engine (1,5i)

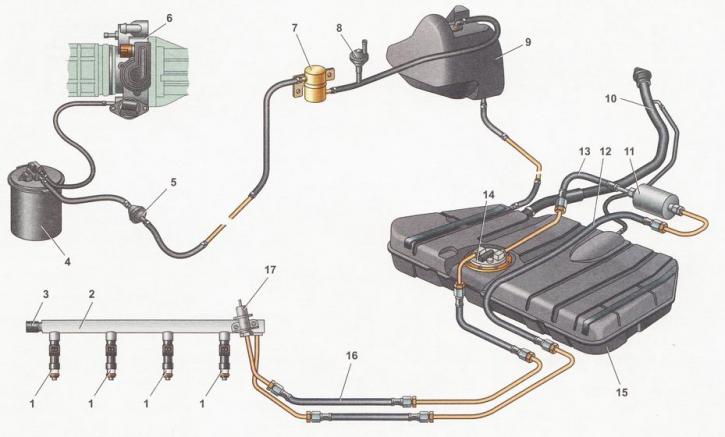

Scheme of the power supply system of the VAZ 2112 engine (l,5i): 1 - nozzles; 2 - fuel rail; 3 - diagnostic fitting of the fuel rail (for checking fuel pressure, closed with screw cap); 4 - adsorber; 5 - check valve; 6 - throttle assembly; 7 - gravity valve; 8 - safety valve; 9 - separator; 10 - filling pipe; 11 - fuel filter; 12 - fuel supply line; 13 - fuel line hose connecting the outlet pipe of the fuel module with the fuel filter; 14 - fuel module; 15 - fuel tank; 16 - drain fuel line; 17 - fuel pressure regulator

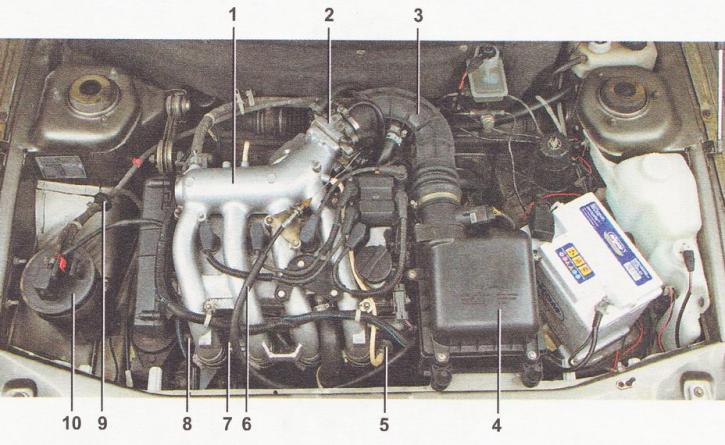

Location of elements of the engine power system * VAZ 2112 (l,5i) in the engine compartment: 1 - receiver; 2 - throttle assembly; 3 - air supply hose to the throttle valve; 4 - air filter; 5 - fuel pressure regulator; 6 - throttle cable; 7 - fuel rail; 8 - diagnostic fitting; 9 - adsorber check valve; 10 - adsorber

* Engine VAZ 2112 (1,5i) with decorative trim removed.

Features of the power supply system of the VAZ 21124 engine (l,6i)

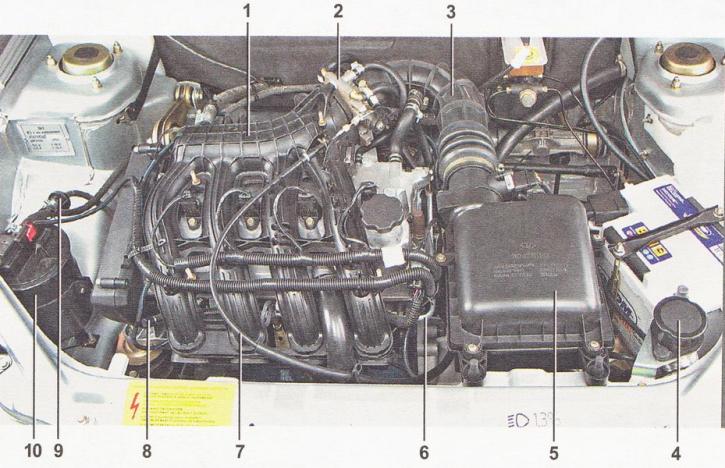

Location of elements of the engine power system * VAZ 21124 (l,6i) in the engine compartment: 1 - inlet module; 2 - throttle assembly; 3 - air supply hose to the throttle valve; 4 - air intake; 5 - air filter; 6 - fuel rail; 7 - throttle cable; 8 - fitting of the fuel rail; 9 - adsorber check valve; 10 - adsorber

* Engine VAZ 21124 (l,6i) with plastic cover removed.

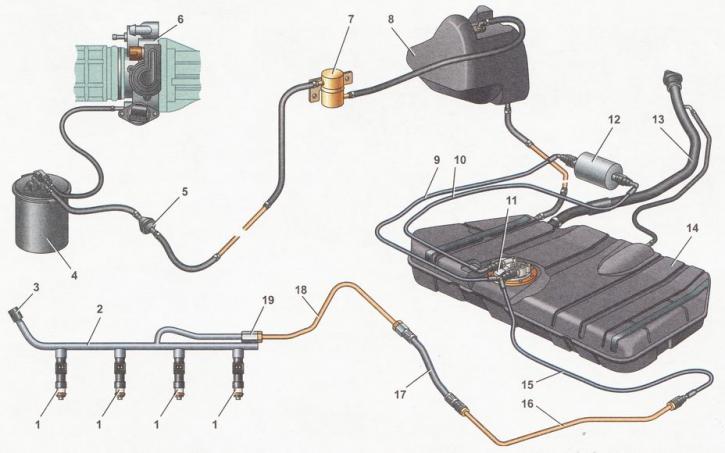

Scheme of the power supply system of the VAZ 21124 engine (1,6i): 1 - nozzles; 2 - fuel rail; 3 - diagnostic fitting of the fuel rail (for checking fuel pressure, closed with screw cap); 4 - adsorber; 5 - check valve; 6 - throttle assembly; 7 - gravity valve; 8 - separator; 9 - fuel line tube connecting the fuel filter to the tee; 10 - fuel line tube connecting the fuel filter with the outlet pipe of the fuel module; 11 - fuel module; 12 - fuel filter; 13 - filling pipe; 14 - fuel tank; 15 - hose connecting the fuel filter and the fuel module with the fuel line; 16, 18 - metal tubes of the fuel line; 17 - connecting hose; 19 - fitting for connecting the fuel rail to the fuel line