Attention. Do not touch the ECU terminals with your hands, as the engine control system is microprocessor-based, its electronic components may be damaged by electrostatic discharge.

Getting Started with Car Repair (especially if the work is related to the dismantling of elements of the engine control system), disconnect the terminal from the negative battery terminal.

Warning. When the battery is disconnected from the vehicle's network, fault codes will be deleted from the computer's memory. Therefore, before checking the engine management system using diagnostic equipment (for example, DST-2M) do not remove the terminals from the battery terminals.

In many cases, to check the elements of the engine control system, it is necessary to have a supply voltage in the electrical circuit of the system. At the same time, disconnect the wire connectors from the sensors

and actuating elements is allowed only after switching off the ignition.

Attention. Disconnect the wiring harness connector from the computer only after removing the terminal from the negative battery terminal.

If you need to connect the battery to the car's electrical network during repairs, first make sure that the disconnected wires (connector pins, wire ends) not closed to «mass», and the ignition is off. Connect the battery positive terminal first and then the negative terminal. Switch on the ignition only for the duration of the measurements.

Attention. The car system uses electronic components, the supply voltage of which is 5 V. Supplying voltage to them from the car's electrical network (voltage in which more than 12 V) will damage the engine control system.

To check the engine management system, use a multimeter; the internal resistance of the device in voltmeter mode must be at least 10 MΩ. If necessary, to check the 12 V power supply circuits, you can use a test lamp, but the lamp power must be less than 4 watts. A control lamp for the instrument panel A 12-1.2-1 with a power of 1.2 W or a cigarette lighter lamp AMN 12-3-1 is suitable (3 W).

Before starting the engine, make sure that the terminals are securely fastened to the battery terminals.

Attention. To avoid failure of the electronic components of the computer, do not disconnect the wire terminals from the battery terminals while the engine is running.

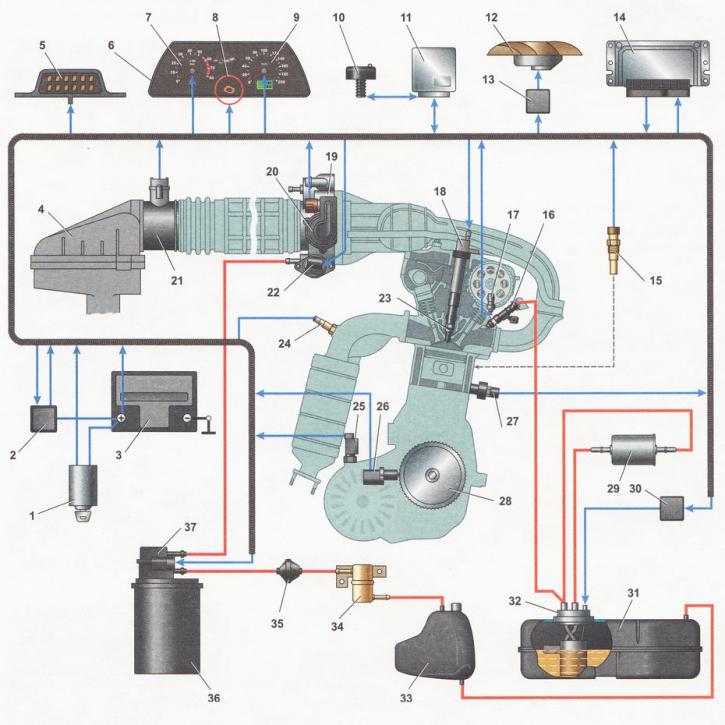

Scheme of the injection engine control system *: 1 - ignition lock; 2 - main relay; 3 - battery; 4 - air filter; 5 - diagnostic connector; 6 - instrument panel; 7 - tachometer; 8 - control lamp for a malfunction of the engine management system; 9 - speedometer; 10 - immobilizer sensor with indicator; 11 - immobilizer control unit; 12 - electric fan of the engine cooling system; 13 - electric fan relay; 14 - electronic control unit (ECU); 15 - coolant temperature sensor; 16 - nozzles; 17 - camshaft position sensor (phase sensor); 18 - ignition coil *; 19 - throttle assembly; 20 - throttle position sensor (TPS); 21 - mass air flow sensor (DMRV); 22 - idle speed controller (IAC); 23 - spark plug; 24 - oxygen concentration sensor *; 25 - vehicle speed sensor; 26 - crankshaft position sensor (DPKV); 27 - knock sensor (DD); 28 - crankshaft pulley; 29 - fuel filter; 30 - fuel pump relay; 31 - fuel tank; 32 - fuel module; 33 - separator; 34 - gravity valve; 35 - check valve; 36 - adsorber; 37 - adsorber purge valve

* The diagram is shown on the example of a car with an injection engine VAZ 21124 (l,6i). By car with a VAZ 2112 engine (l,5i) instead of four coils, an ignition module is installed; the oxygen concentration sensor is installed in the intake pipe.