Work sequence

1. We prepare the car for repair work (see points 1 and 2a "Preparing the car for maintenance and repair")

2. Holding the adjusting nut of the clutch drive with a 13 mm wrench, with the second key of the same we unscrew the lock nut a few turns.

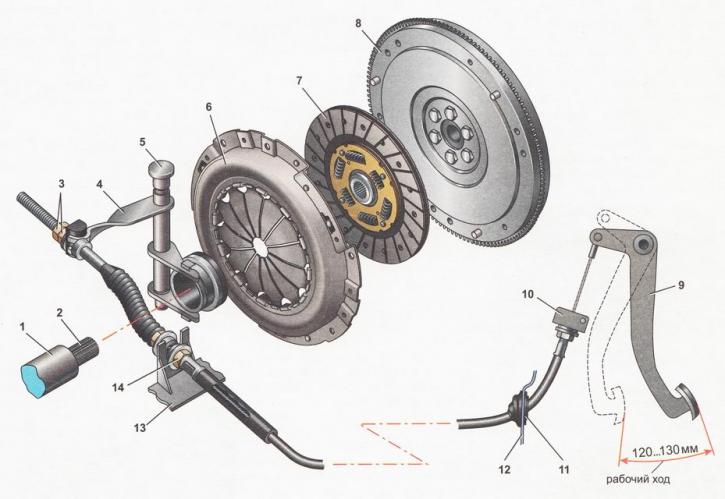

3. By screwing or unscrewing the adjusting nut, we ensure that the clutch pedal travel is 120-130 mm (see fig.).

4. Having completed the adjustment of the drive, we stop the adjusting nut with a lock nut.

Device, clutch drive circuit on VAZ 2110 cars: 1 - guide sleeve of the clutch release bearing; 2 - the input shaft of the gearbox; 3 - cable adjusting nuts; 4 - clutch release fork; 5 - sleeve of the axle of the clutch release fork; 6 - pressure plate assembly (clutch basket); 7 - driven clutch disc; 8 - engine flywheel; 9 - clutch pedal; 10 - cable sheath bracket; 11 - anther; 12 - partition of the engine compartment; 13 - bracket on the gearbox housing; 14 - nuts for fastening the cable sheath