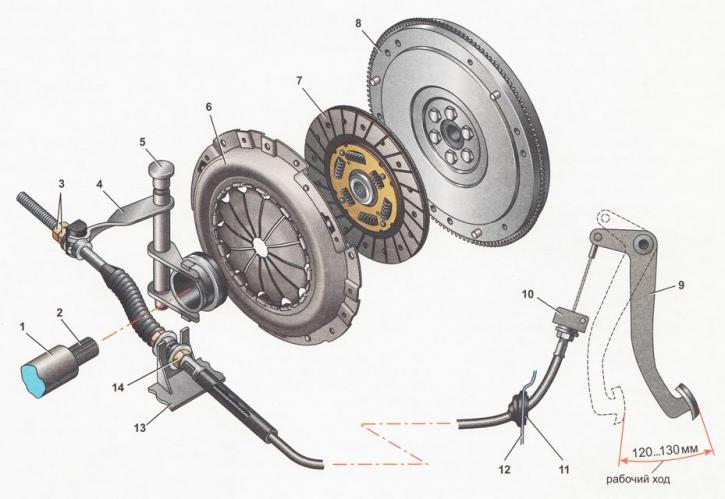

The clutch is mounted on the flywheel and is covered by an aluminum crankcase that is bolted to the cylinder block. On the other hand, the clutch housing is connected to the gearbox housing.

On the splines of the input shaft of the gearbox, a clutch driven disk is freely installed, divided by radial slots into twelve sectors. Friction linings made of a special material are riveted to the clutch disc on both sides. The torque from the clutch disc to its hub is transmitted through a spring damper (vibration damper).

Leading part of the clutch (basket) attached to the flywheel with six bolts. The clutch basket includes a pressure plate, a casing and a diaphragm pressure spring. The pressure plate is movably fixed on elastic plates inside the casing. Under the action of the diaphragm spring, the clutch disc is clamped between the pressure plate and the flywheel.

The clutch is disengaged when the clutch pedal is depressed. The upper tip of the cable is pivotally attached to the clutch pedal. The lower tip of the cable is pivotally connected to the clutch release fork, the axis of which is mounted on two plastic bushings in the clutch housing.

Clutch release bearing - ball, angular contact. The clutch release bearing sleeve is put on the guide sleeve and is pressed against the clutch release fork by a spring. When the clutch fork is turned, the release bearing moves longitudinally along the guide sleeve.

The clutch release bearing is constantly pressed against the petals of the diaphragm pressure spring and rotates with it.

When the clutch is engaged, its driving and driven parts rotate as one, transferring torque from the engine crankshaft to the gearbox input shaft. When the clutch pedal is pressed, the clutch release fork, turning, moves the release bearing with its clutch along the guide sleeve. The clutch release bearing acts on the diaphragm spring, which, bending, takes the pressure plate away from the driven one and the transmission of torque stops. When the pedal is released, all parts of the clutch return to their original position under the action of the springs.

Clutch drive adjustment (pedal travel) is carried out by changing the position of the lower tip of the cable sheath in the bracket for its fastening.

On vehicles with VAZ 2112 engines (1,5i) and VAZ 21124 (1,6i) the drive and pressure plates of the clutch are installed, which are not interchangeable with other front-wheel drive VAZ models. You can distinguish them by the hole between the petals of the diaphragm spring...

...and two offset damper springs.

Device, clutch scheme on a VAZ 2110 car: 1 - guide sleeve of the clutch release bearing; 2 - the input shaft of the gearbox; 3 - cable adjusting nuts; 4 - clutch release fork; 5 - sleeve of the axle of the clutch release fork; 6 - pressure plate assembly (clutch basket); 7 - driven clutch disc; 8 - engine flywheel; 9 - clutch pedal; 10 - cable sheath bracket; 11 - anther; 12 - partition of the engine compartment; 13 - bracket on the gearbox housing; 14 - nuts for fastening the cable sheath