Checking the oil level in the gearbox (see "Gearbox - oil level check"). In a gearbox operated with a low oil level in the crankcase, intensive wear of parts occurs and soon they may fail and, as a result, the gearbox should be replaced.

On an inspection hole or overpass, we inspect the gearbox from all sides, make sure that there is no oil leakage at the junctions of the crankcases and the gearbox cover, as well as through the oil seals of the wheel drives and the gear selector rod.

By pressing the clutch pedal, we turn on all the gears in turn, check the clarity of their inclusion and deactivation. If necessary, adjust the gearshift mechanism (see section "Gearshift drive - disassembly and assembly").

Set the gear lever to neutral position and start the engine on the car. Pressing the clutch pedal several times, we listen to the sound of the operation of the gearbox bearings. It appears when the clutch pedal is released and disappears when it is pressed. The loud noise of the bearings indicates wear.

We check the operation of the gearbox in motion. To do this, moving first with acceleration, and then with deceleration, we shift gears with an increase, and then with a decrease. We check the clarity of switching on and off gears while driving, the operation of synchronizers. We make sure that there are no crunches, knocks and other extraneous sounds during the operation of the box, as well as spontaneous disengagement of gears when the load changes.

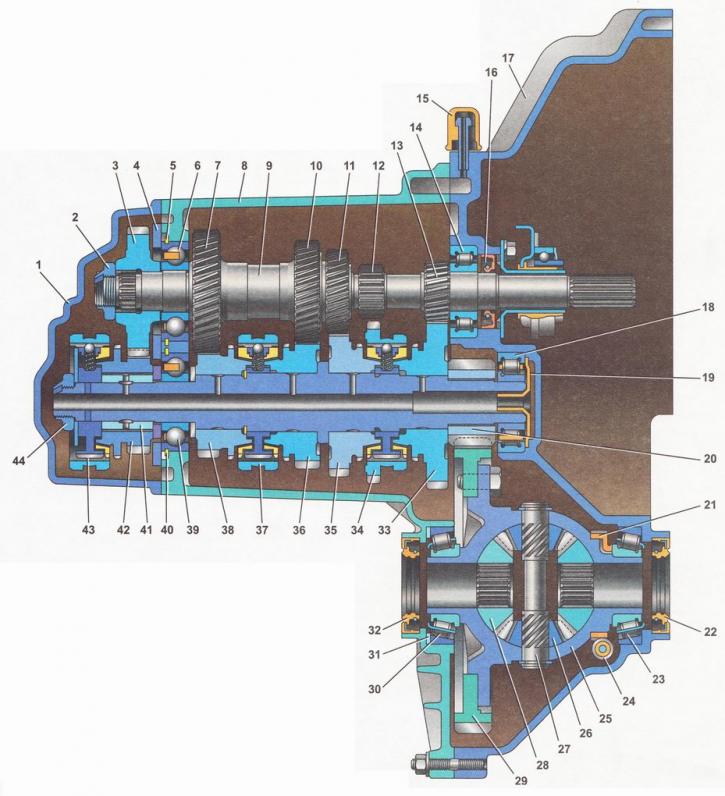

Scheme of the VAZ 2110 gearbox: 1 - rear cover of the gearbox housing; 2, 44 - nut; 3 - fifth gear drive gear; 4 - thrust plate; 5, 40 - bearing lock ring; 6 - ball bearing of the primary shaft; 7 - the drive gear of the fourth gear; 8 - gearbox housing; 9 - input shaft; 10 - third gear drive gear; 11 - second gear drive gear; 12 - reverse gear; 13 - drive gear of the first gear; 14 - roller bearing; 15 - breather; 16 - input shaft seal; 17 - clutch housing; 18 - roller bearing of the secondary shaft; 19 - oil collector; 20 - main gear drive gear; 21 - plastic drive gear of the speed sensor drive; 22, 32 - drive gland; 23, 30 - differential tapered roller bearing; 24 - speed sensor drive; 25 - differential box; 26 - differential satellite; 27 - axis of the satellites; 28 - side gear; 29 - driven gear of the main gear; 31 - adjusting ring; 33 - driven gear of the first gear; 34 - synchronizer of the first and second gears; 35 - driven gear of the second gear; 36 - driven gear of the third gear; 37 - synchronizer of the third and fourth gears; 38 - driven gear of the fourth gear; 39 - ball bearing of the secondary shaft; 41 - bushing; 42 - driven gear of the fifth gear; 43 - fifth gear synchronizer